Bridge pier and abutment construction equipment with automatic construction correction of circular sunk well

A technology for construction equipment and caissons, which is applied in the fields of caissons, infrastructure engineering, construction, etc., can solve the problems of artificially built scaffolds that cannot be moved, complicated operation of caissons and scaffolds, and unstable scaffolds, etc., achieving small engineering volume and short time-consuming , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

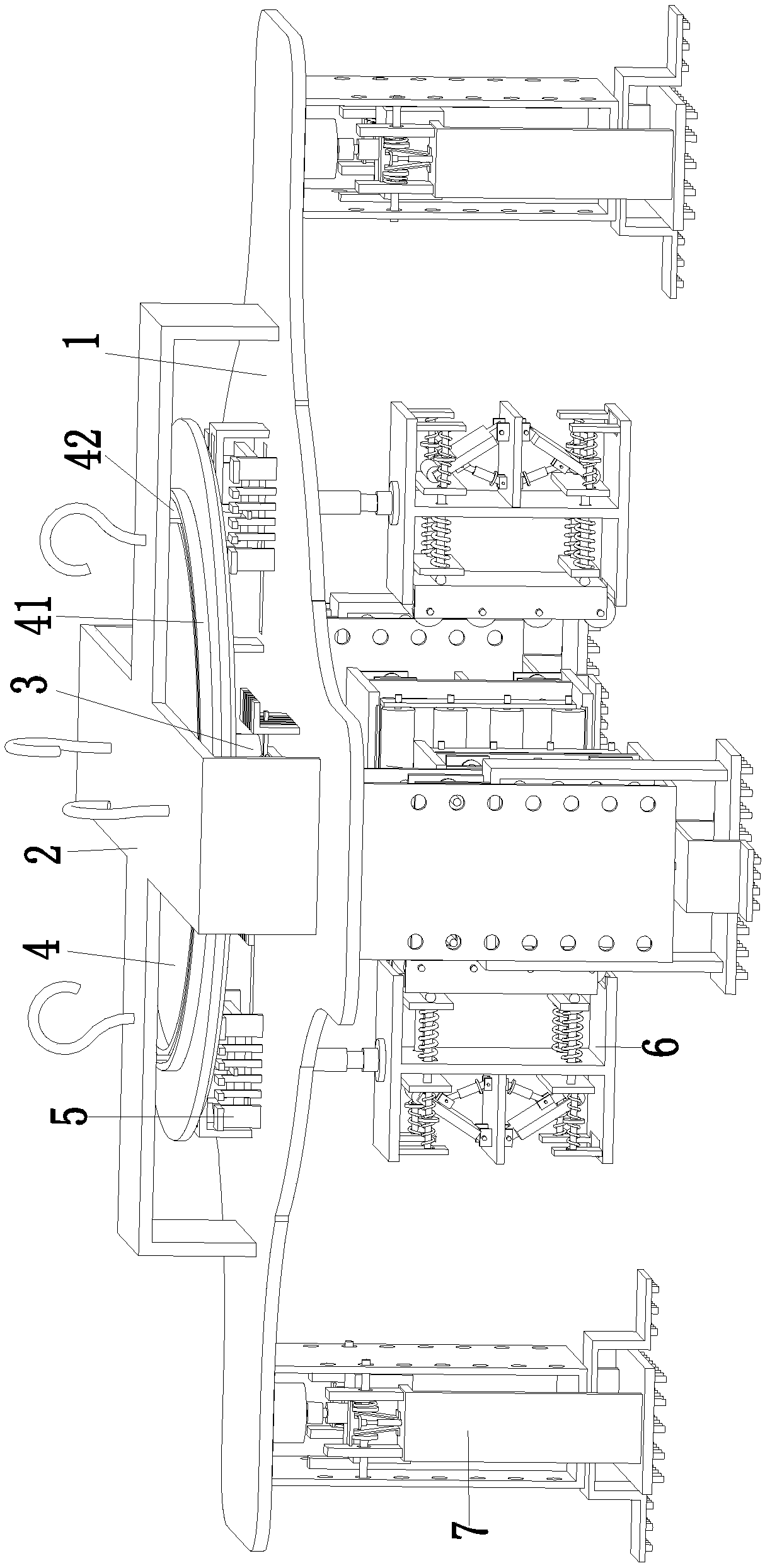

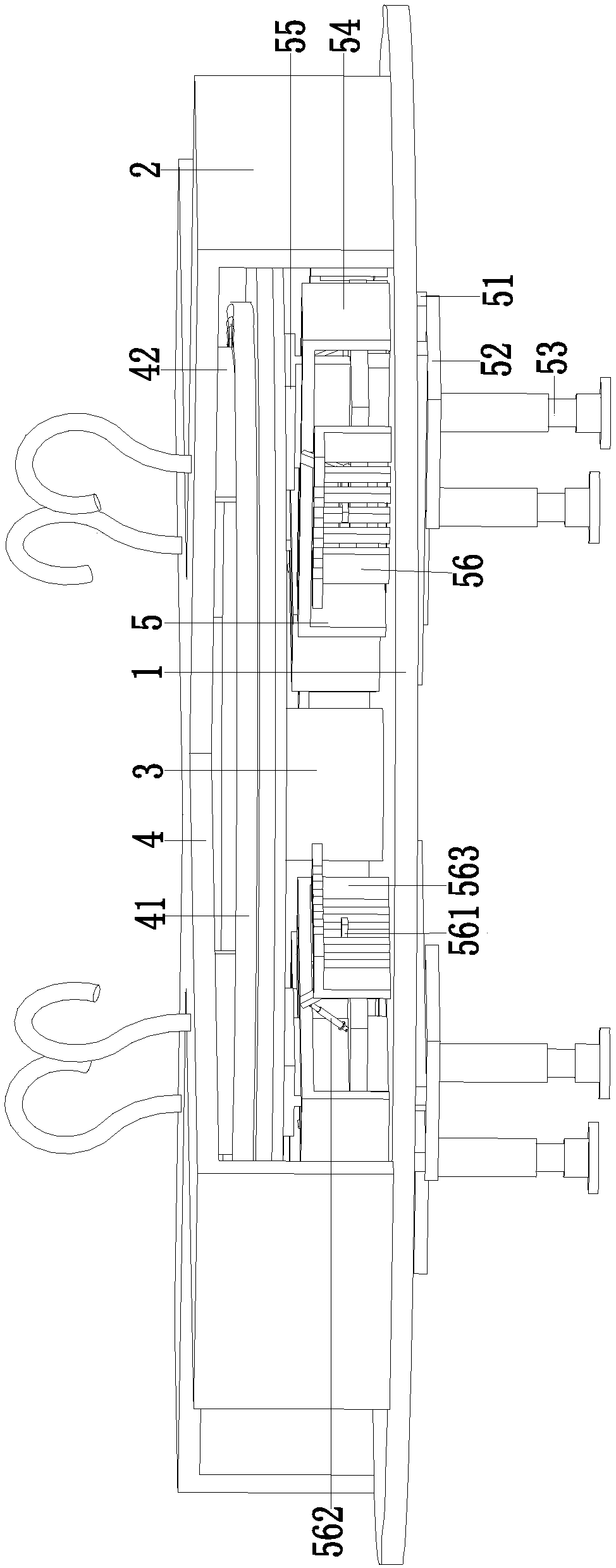

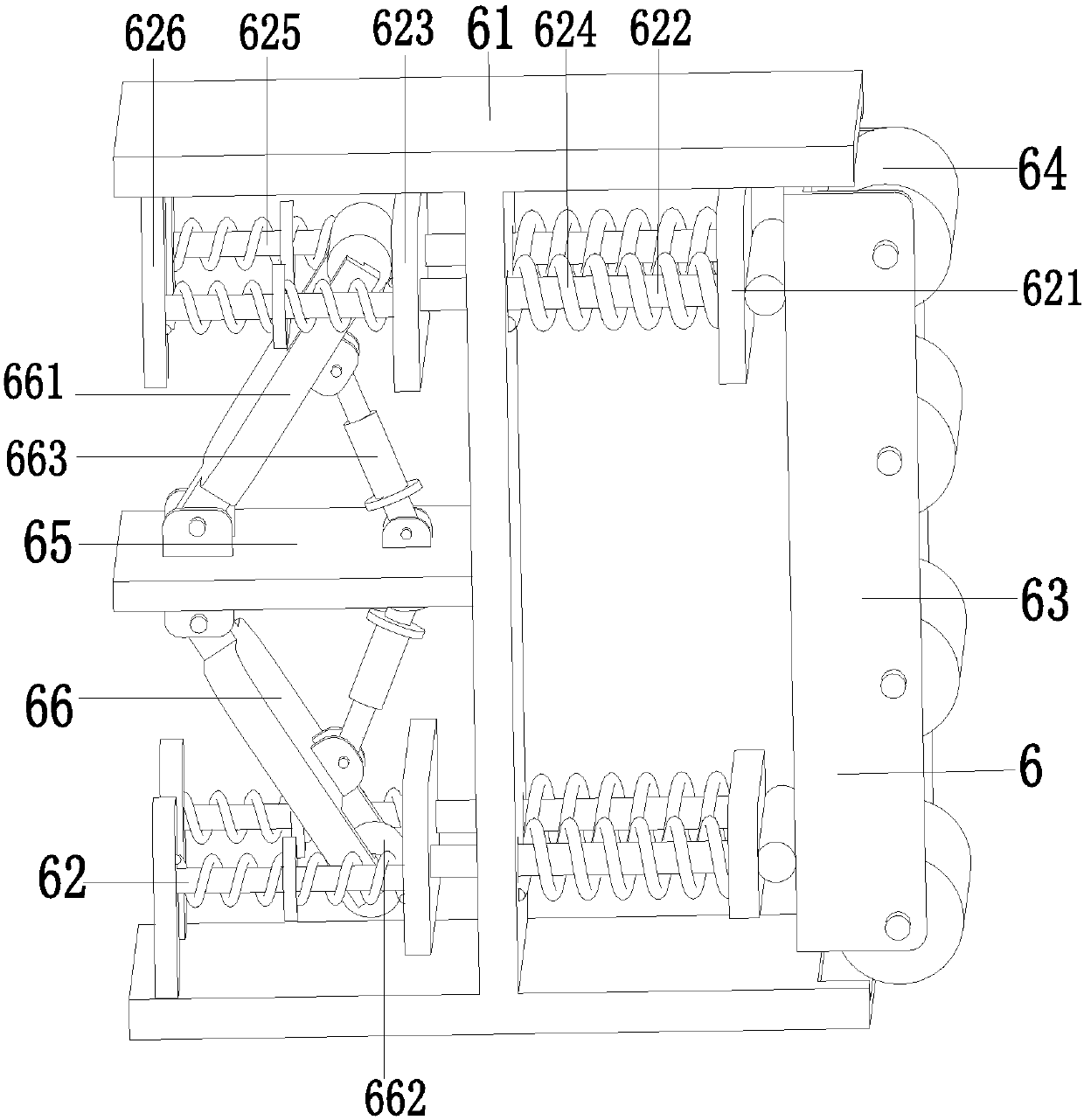

[0027] Such as Figure 1 to Figure 4 As shown, a circular caisson can be automatically constructed and corrected bridge pier construction equipment, including a hoisting plate 1, a hoisting frame 2 is installed on the hoisting plate 1, and the hoisting frame 2 can ensure that the existing hoisting equipment can be hoisted stably In the present invention, the inner side of the hoisting plate 1 is provided with a correction moving groove along its circumferential direction, the hoisting drive motor 3 is installed on the hoisting plate 1 through the motor base, and the hoisting drive plate 4 is installed on the output shaft of the hoisting drive motor 3, and the hoisting drive The lower end of the plate 4 is provided with a plane thread, and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com