Staged flow constraining debris flow drainage slot and application thereof

A debris flow and drainage channel technology, which is applied in water conservancy projects, artificial waterways, embankments, etc., can solve the problems of reducing the movement speed of debris flow and cannot effectively reduce the flow energy of debris flow, so as to reduce the movement speed, increase protection efficiency, and enhance turbulence. Use the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

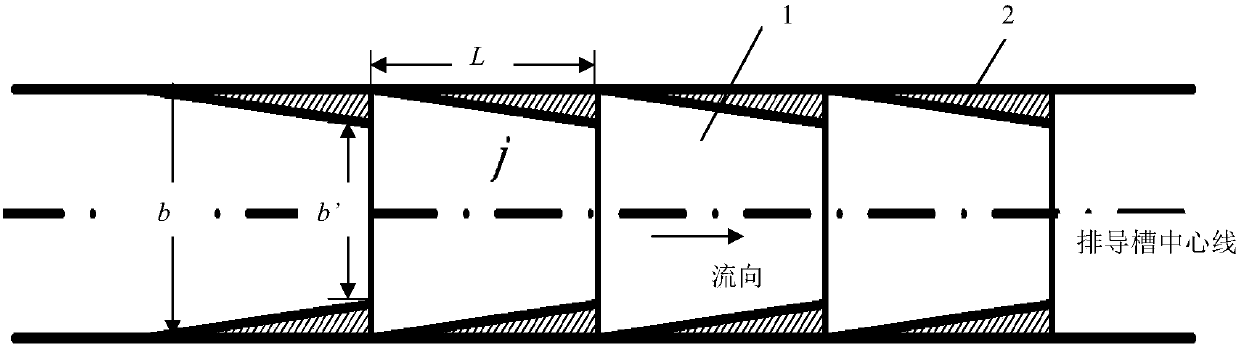

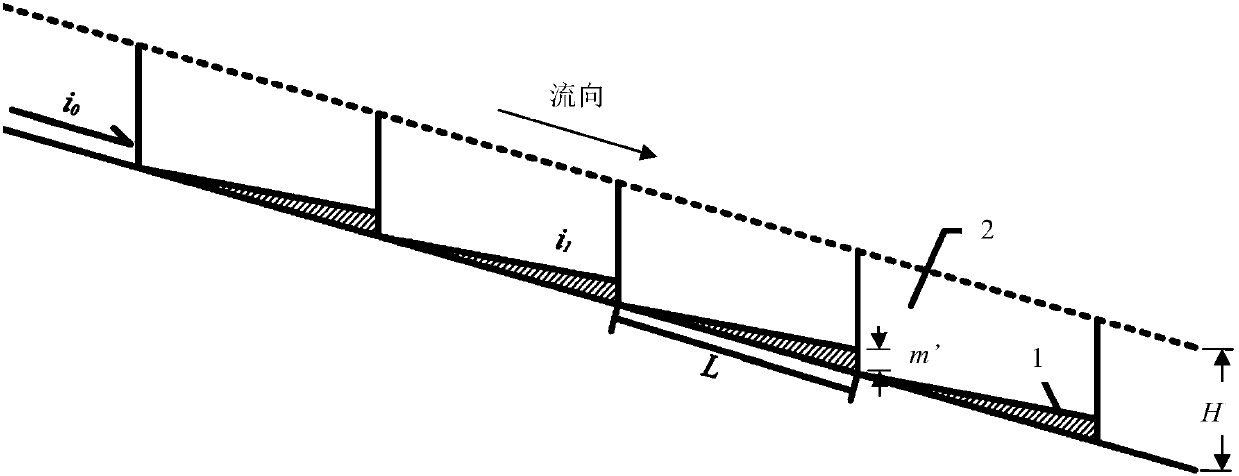

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 shown. The drainage area of a debris flow is 0.65km 2 , Debris flow ditch bed longitudinal gradient i 0 15% at P 2% Under the design standard, the flow of debris flow is 60m 3 / s, it is planned to build a debris flow drainage channel for protection. Due to the large slope of the channel, the debris flow will generally not be deposited in the drainage channel when it is released. On the contrary, due to the high kinetic energy of the debris flow, when it reaches the downstream protection area, it will cause serious damage. One of the important functions of building the drainage channel is to consume part of the kinetic energy in the debris flow, reduce the velocity of the debris flow, and reduce the damage of the debris fluid to the downstream. Therefore, the stage beam type debris flow drainage channel of the present invention is adopted.

[0024] The beam-type debris flow drainage trough of the stage include...

Embodiment 2

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 shown. A debris flow basin area of 6.0km 2 , Debris flow ditch bed longitudinal gradient i 0 30% at P 2% Under the design standard, the flow of debris flow is 200m 3 / s, it is planned to build the stage beam type debris flow drainage channel of the present invention along the debris flow channel for protection.

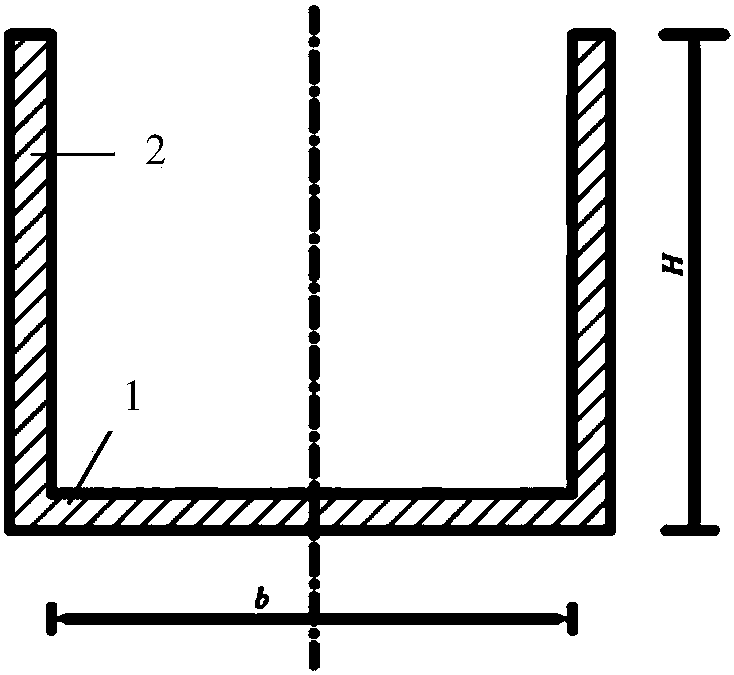

[0027]The beam-type debris flow drainage trough of the stage includes 20 sections of beam structures connected end to end; The flow section is exactly the same; the beam structure includes the bottom 1 of the tank and the side walls 2 on both sides. The bottom 1 of the tank gradually rises along the flow direction of the debris flow, and the side walls 2 on both sides gradually narrow toward the center line of the drainage channel along the flow direction of the debris flow. Tank bottom 1 vertical slope i 1 is 20%, the lifting rate of the tank bottom 1 is 0.063; the shrinkage width of the side wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com