Centrifugation and dynamic adsorption combination oil-water separation device

An oil-water separation device and oil-absorbing cotton technology, which is applied in the field of oil pollution treatment, can solve the problems that oil cannot be recycled and reused, there is no high oil-water separation efficiency, and oil-water selectivity is poor, so as to improve the reuse performance and oil-water separation Efficiency, recovery effect of oil absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

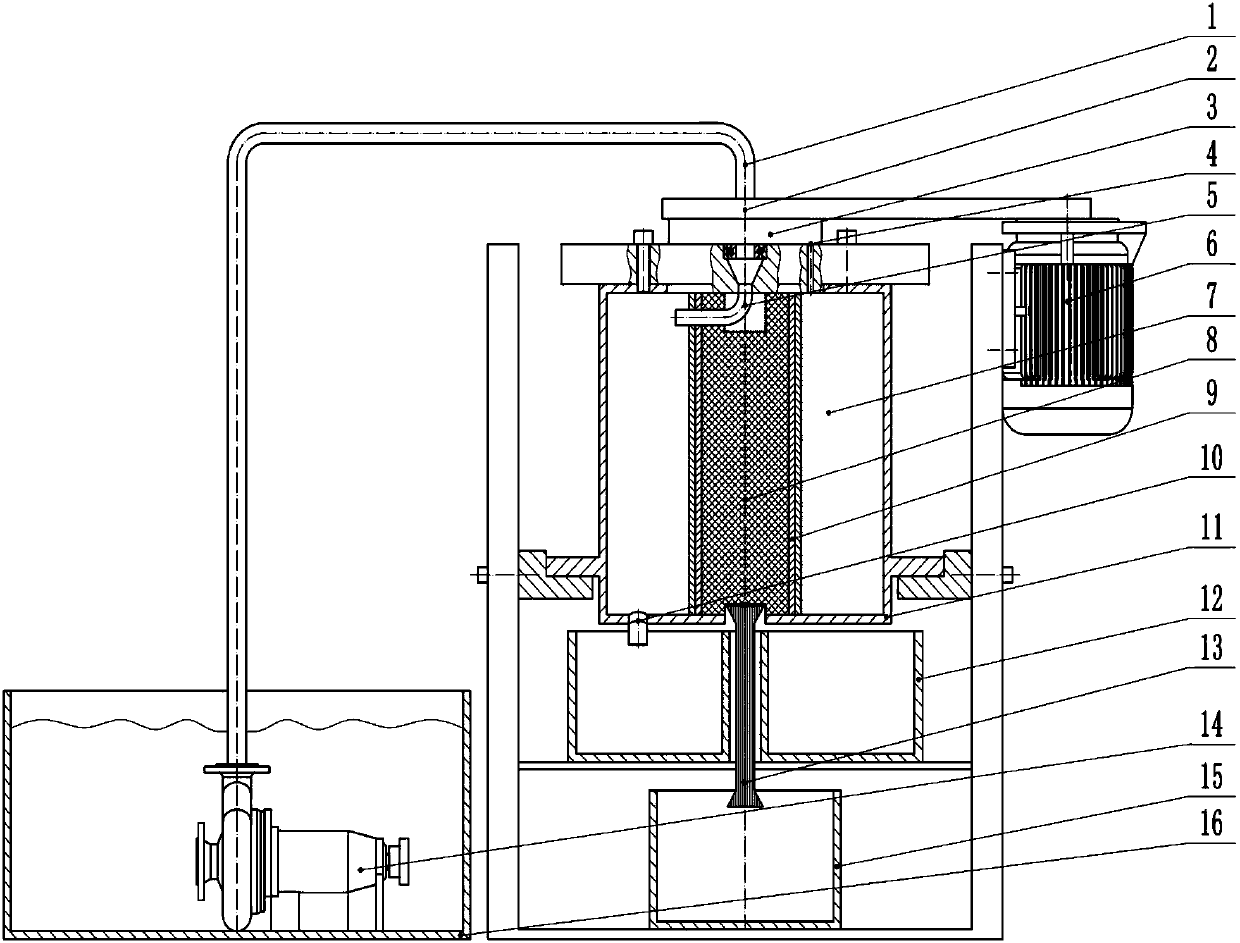

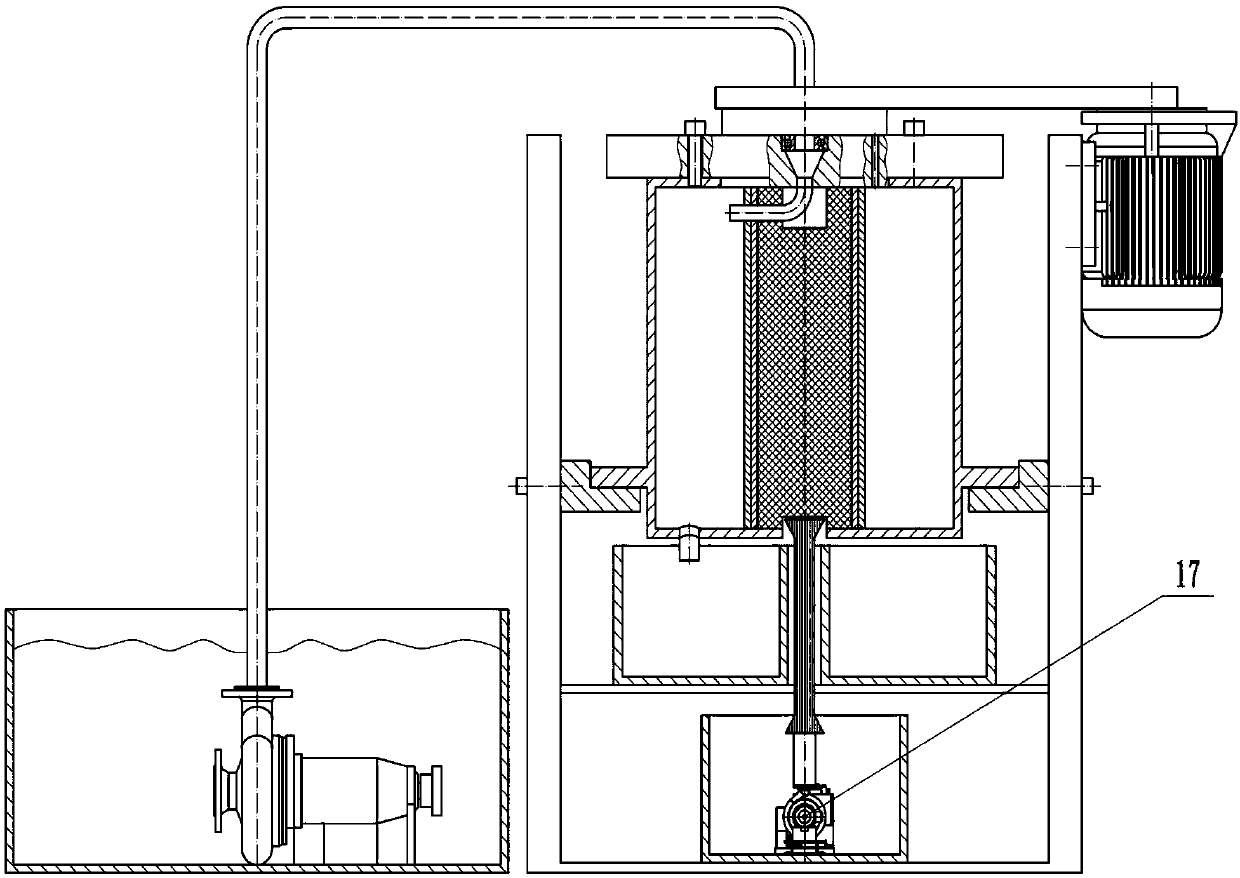

[0016] The present invention is an oil-water separation device combined with centrifugal and dynamic adsorption, such as figure 1 As shown, it mainly includes: a rotating device 3, a motor 6, an oil-water separation device 7, an oriented nanofiber oil delivery pipe 13 and a collecting device. The collection device is mainly composed of a drainage cylinder 12 and an oil storage cylinder 14 . The oil-water separation device 7 mainly includes: a nanofiber oil-absorbing cotton layer 8 , a demulsification filter membrane 9 , a water outlet 10 and a casing 11 . The shell 11 is made of transparent plastic to facilitate observation of the oil-water separation process; 2-3 layers of demulsification filter mesh 9 are arranged inwardly. This filter mesh is a porous composite membrane with a fiber drawing structure on the surface. The average particle size of emulsified oil is similar. When the emulsified oil-water mixture between the filter mesh and the shell passes through the filter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com