A method for igniting and starting a boiling chlorination furnace with a plasma gun

A boiling chlorination furnace and plasma gun technology, applied in the direction of combustion, titanium tetrachloride, incandescent ignition, etc., can solve the problems of aggravated equipment, corrosion, and high heating of local raw materials, so as to prevent overheating and sintering, shorten reaction time, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

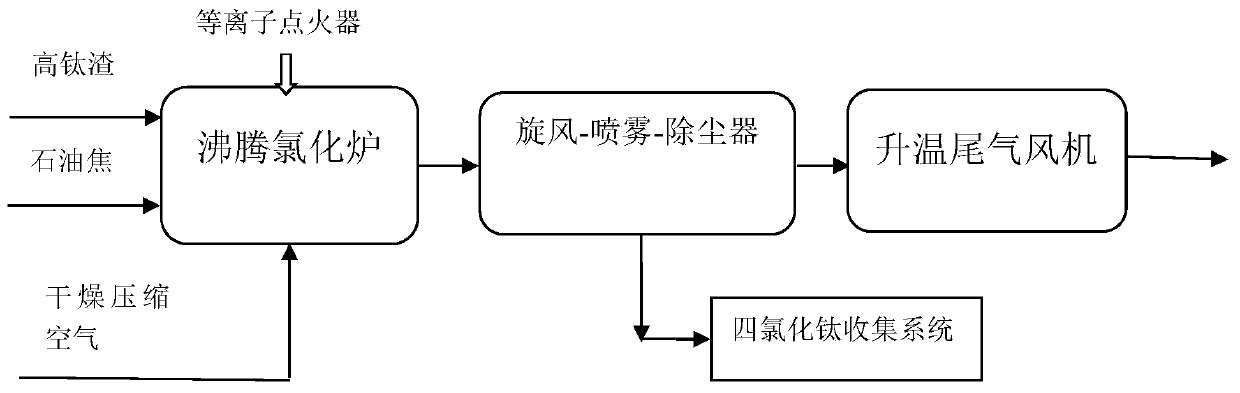

Image

Examples

Embodiment 1

[0065] In this embodiment, at 6000kg / d TiCl 4 The fluidized fluidized furnace is ignited and opened on the industrial test device. The specific implementation is as follows:

[0066] 1) After the plasma gun ignition device is debugged outside the furnace, connect the plasma gun ignition device with the boiling chlorination furnace device system, and complete the inspection and debugging of the entire device system and make preparations;

[0067] 2) According to the ratio of high-titanium slag:petroleum coke=100:20, pre-mix the bed material, manually spread and fill it into the boiling chamber to form a raw material bed with an average thickness of 600mm, and the ignition port of the fluidized chlorination furnace is located above the raw material bed 400m-500mm.

[0068] 3) Debugging and setting the gas flow parameters of the four fluidized states of the fluidized fluidized furnace:

[0069] S1: Set the compressed air flow and pressure indicators of the bubbling bed: slowly o...

Embodiment 2

[0081] The specific implementation of this embodiment is as follows:

[0082] 1) With step 1 specific operation steps in embodiment 1, debug instrument, meter, equipment, and do the preparatory work;

[0083] 2) According to the ratio of high-titanium slag:petroleum coke=100:40, pre-mix the bed material, manually spread and fill it into the boiling chamber to form a raw material bed with an average thickness of 700mm, and the ignition port of the fluidized chlorination furnace is located above the raw material bed 450m.

[0084] 3) Debug and set the gas flow parameters of the four fluidized states of the raw material bed in the fluidized fluidized furnace:

[0085] s1: Set the compressed air flow rate and pressure index of the bubbling bed: slowly open the furnace bottom ventilation valve, feed dry compressed air into the gas distribution chamber of the fluidized fluidized furnace, and visually observe the raw material bed of the furnace through the observation hole to reach ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com