Variable-speed driving system

A technology of variable speed drive and deceleration transmission, applied in the field of vehicle wheel hub and two-stage variable speed drive system, can solve the problems of energy-consuming and time-consuming, and achieve the effect of compact structure, improved reliability, and optimized structure setting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In the following detailed description, reference is made to the accompanying drawings, which form a part of this specification. In the drawings, identical or similar reference numbers typically identify identical or similar components, unless the text indicates otherwise. The embodiments described in the detailed description and drawings are not meant to be limiting. Other embodiments may be utilized and other changes may be made without departing from the spirit and / or scope of the invention. It should be understood that the aspects of the invention generally described in this specification and shown in the drawings can be arranged, replaced, combined, separated and designed in various configurations.

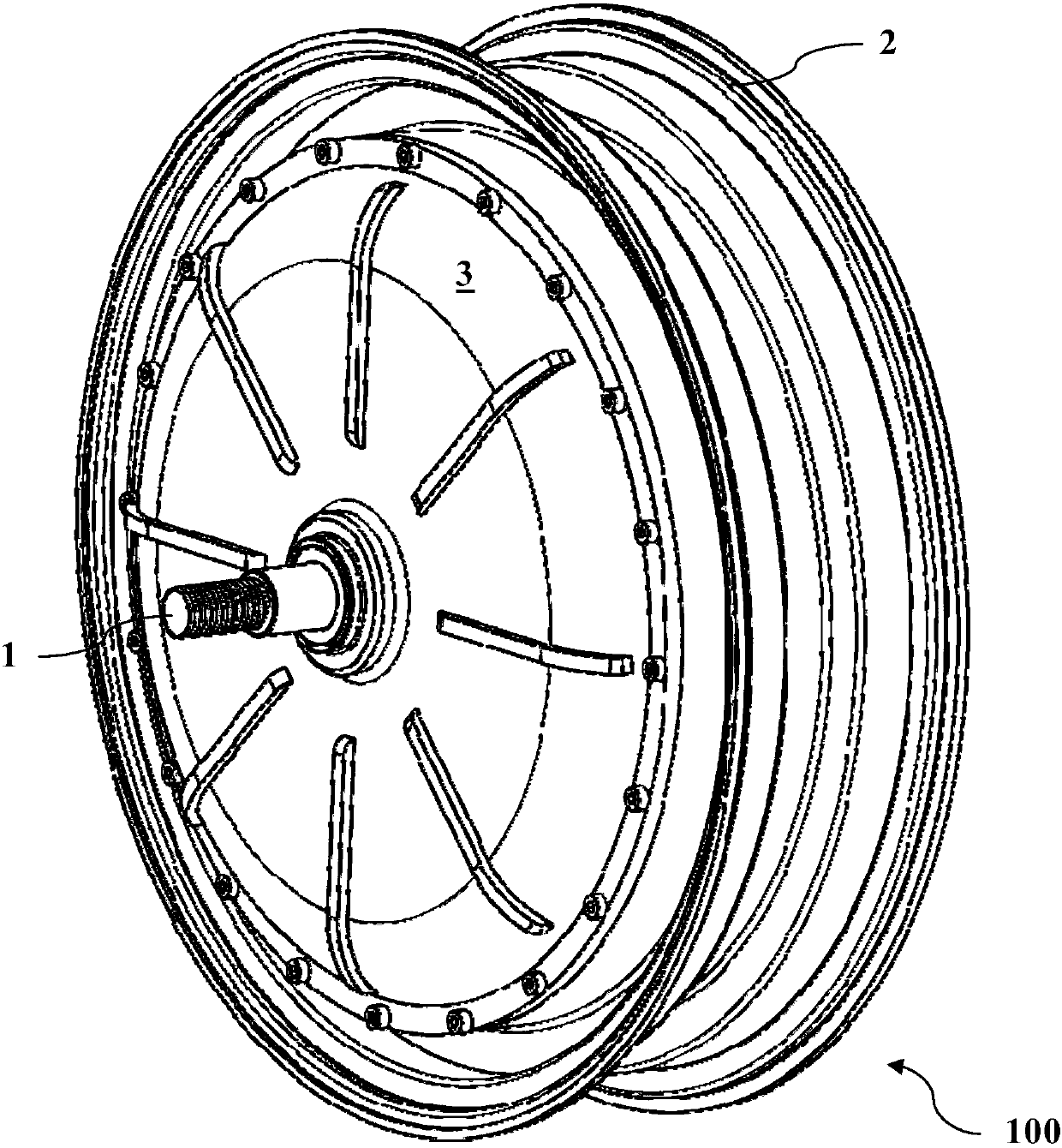

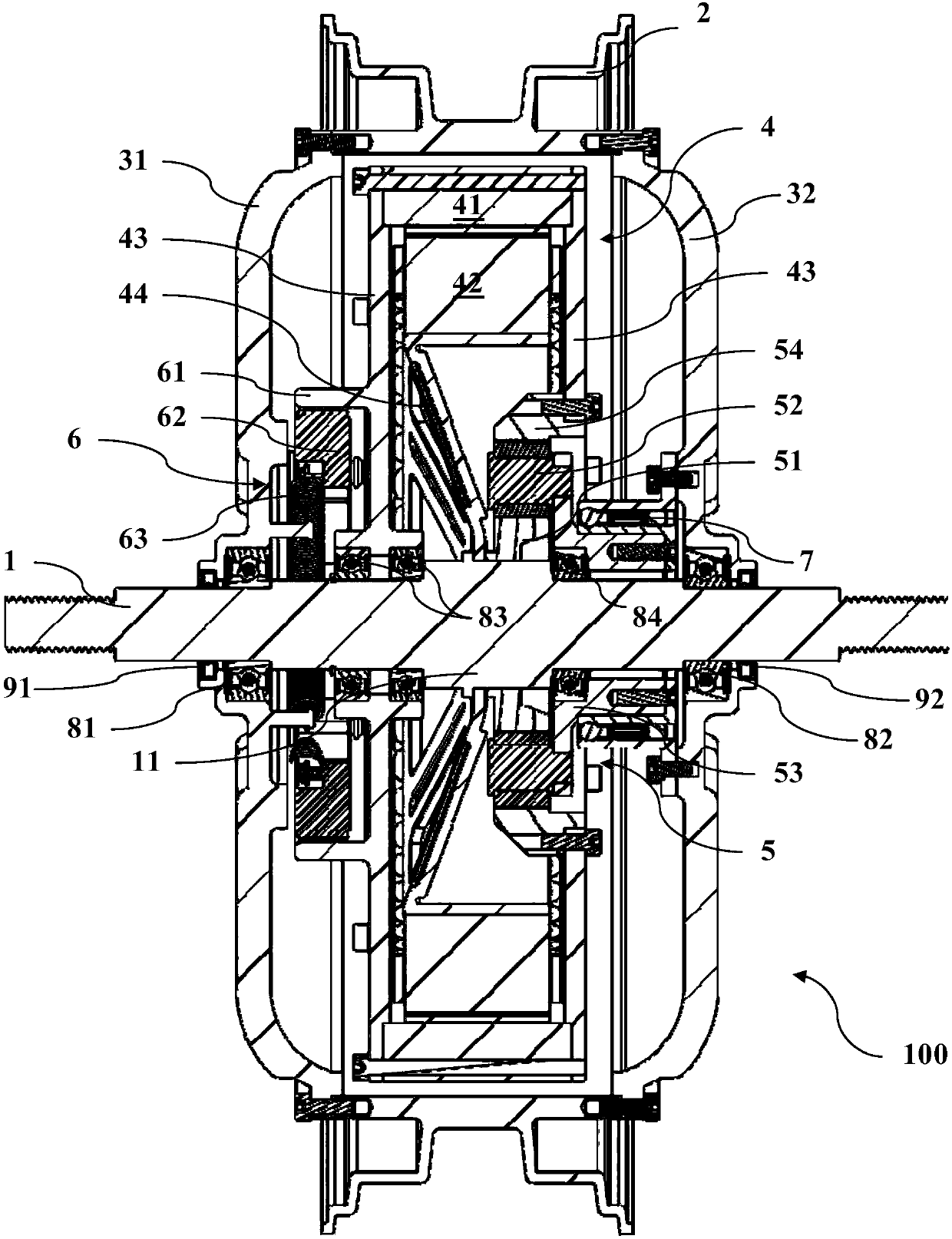

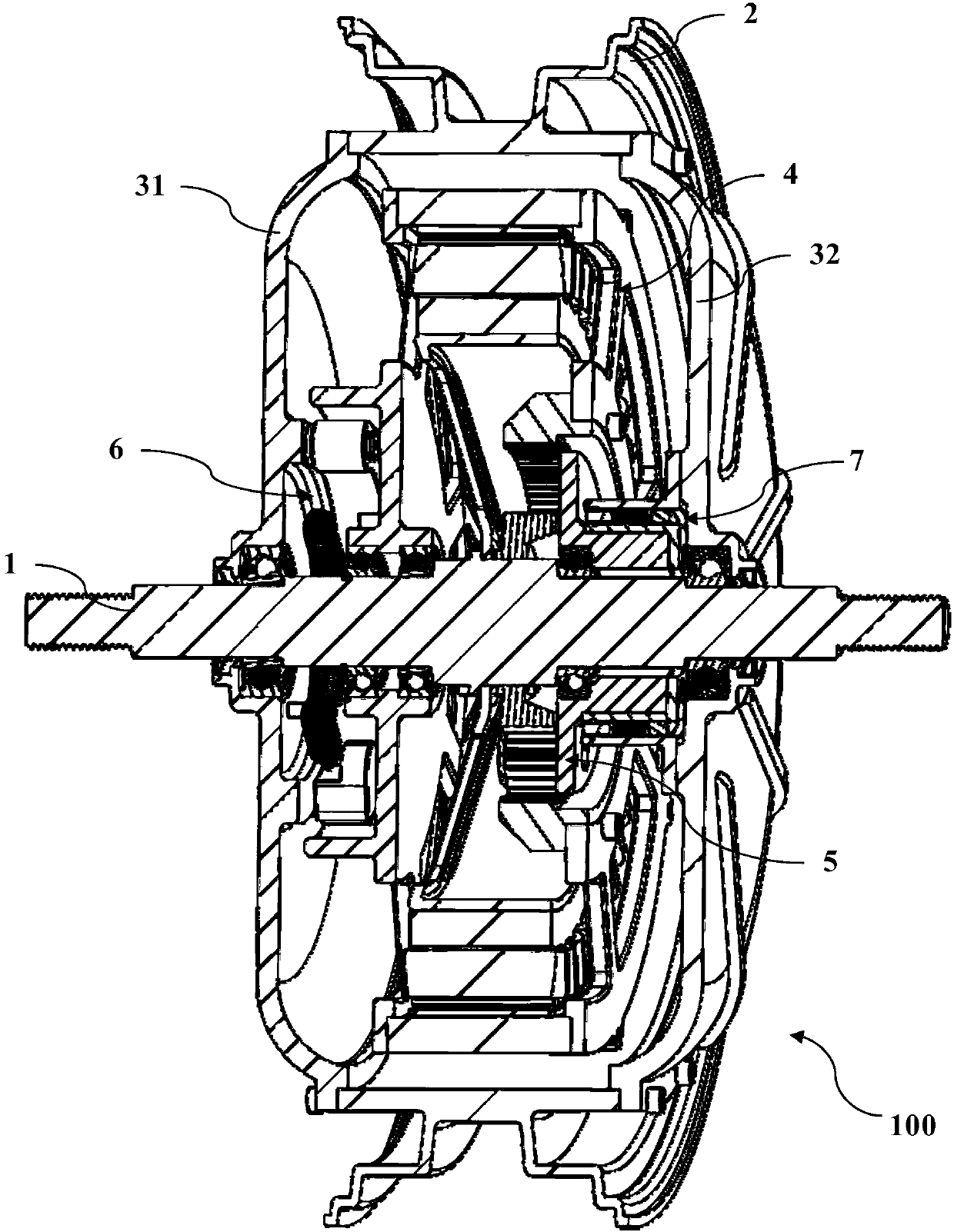

[0028] figure 1 A schematic perspective view of a variable speed drive system 100 according to the invention is shown. figure 2 show figure 1 A schematic longitudinal section view of a variable speed drive system 100, image 3 show figure 2 A vertical cross-sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com