Preparation method of ternary positive electrode material NCA precursor

A positive electrode material and precursor technology, which is applied in the field of precursor preparation, can solve the problems such as the inhomogeneous particle size of nickel hydroxide, cobalt and aluminum substances, affecting quality stability and production efficiency, and the inability to fix and unify the process. Equipment maintenance, conducive to stable operation and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] The invention as figure 1 As shown, a preparation method of NCA precursor of ternary positive electrode material is characterized in that it includes the following steps: (1) mixing the water-soluble salt of Ni, the water-soluble salt of Co and the water-soluble salt of Al and preparing an aqueous solution , to obtain a mixed ion solution; (2) fix NaOH and NH 3 ·H 2 O The flow rate of the mixed solution is 300-600L / h. The mixed ion solution described in step (1) is continuously added to the reactor for equimolar synthesis reaction, and the flow rate is constantly adjusted to stabilize the pH value of the reaction, and then heated and stirred. Obtaining a mixed alkali solution; (3) performing solid-liquid separation on the mixed alkali solution in step (2), washing and drying the obtained solid to obtain an NCA precursor of a ternary positive electrode material.

[0014] In this embodiment, the mixed ion solution includes Ni 2+ 、Co 2+ and Al 3+ , the concentration o...

Embodiment 1

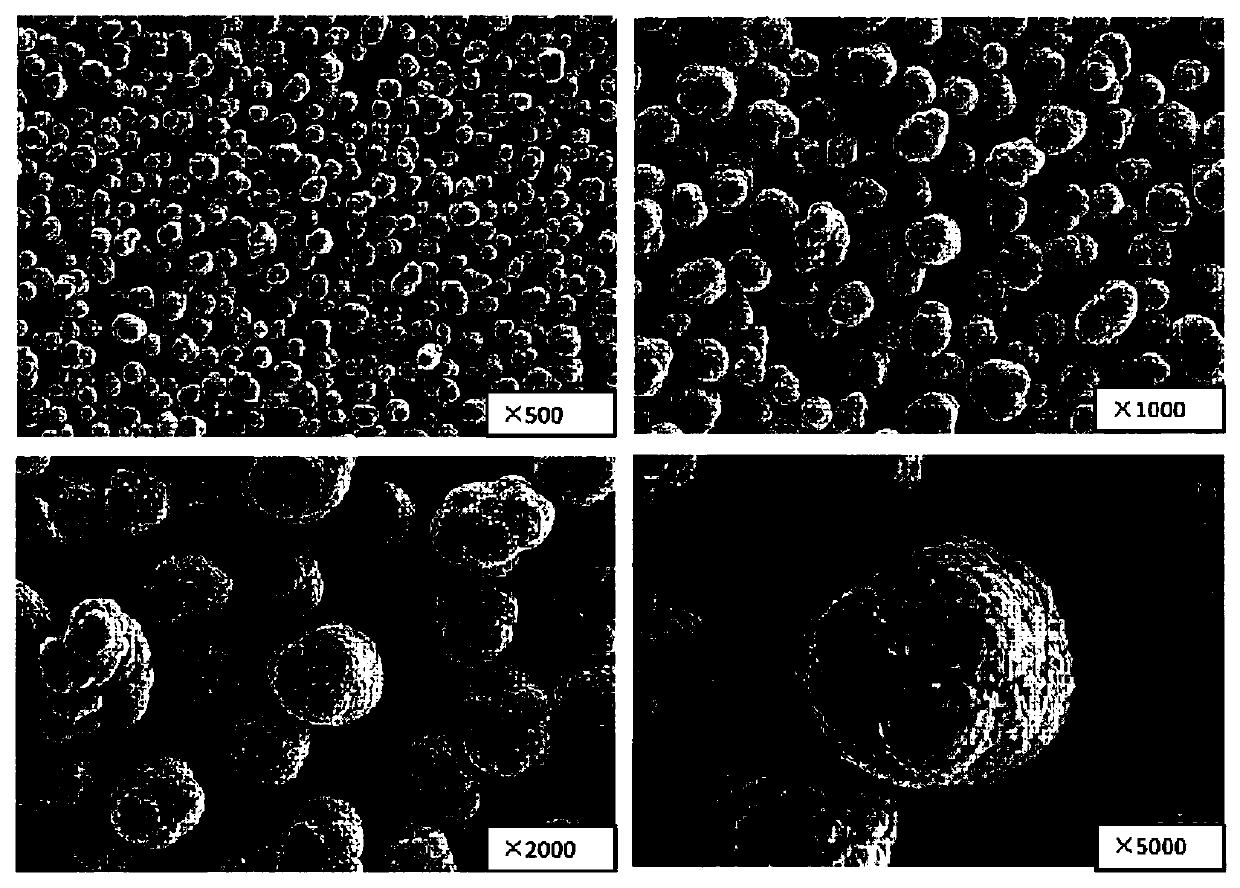

[0019] Example 1: (1) The water-soluble salt of Ni, the water-soluble salt of Co and the water-soluble salt of Al are mixed and formulated into an aqueous solution to obtain a mixed ion solution; wherein the mixed ion solution includes Ni 2+ 、Co 2+ and Al 3+ The concentration of mixed ions is 0.8mol / L; (2) fix NaOH and NH 3 ·H 2 The flow rate of the O mixed solution is 300L / h. The mixed ion solution described in step (1) is continuously added to the reactor for equimolar synthesis reaction, and the flow rate is constantly adjusted to stabilize the pH value of the reaction. The temperature of the reactor is 30°C , the stirring speed is 600r / min; wherein, the NaOH concentration of the mixed alkali solution is 1.6mol / L, NH 3 ·H 2 The concentration of O is 0.05mol / L; (3) The synthetic product of step (2) is subjected to solid-liquid separation, and the obtained solid is washed and dried to obtain the NCA precursor of the ternary cathode material, and the obtained ternary precu...

Embodiment 2

[0020] Example 2: (1) The water-soluble salt of Ni, the water-soluble salt of Co and the water-soluble salt of Al are mixed and formulated into an aqueous solution to obtain a mixed ion solution; wherein the mixed ion solution includes Ni 2+ 、Co 2+ and Al 3+ The mixed ion concentration is 2mol / L; (2) fix NaOH and NH 3 ·H 2 O The flow rate of the mixed solution is 500L / h. The mixed ion solution in (1) is continuously added to the reactor for equimolar synthesis reaction, and the flow rate is constantly adjusted to stabilize the pH value of the reaction. The temperature of the reactor is 55.3°C. Stirring speed is 900r / min; Wherein, the NaOH concentration of described mixed alkali solution is 4mol / L, NH 3 ·H 2 The concentration of O is 0.8mol / L; (3) The synthetic product of step (2) is subjected to solid-liquid separation, and the obtained solid is washed and dried to obtain the NCA precursor of the ternary cathode material, and the obtained ternary precursor—Nickel Cobalt Al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com