Multi-loop coupled heat conduction passive waste heat discharging system test simulation device

A simulation device, passive waste heat technology, applied in cooling devices, nuclear power generation, climate sustainability, etc., can solve the problems that do not meet the experimental requirements of passive waste heat removal system, and achieve the effect of improving the ability of heat removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

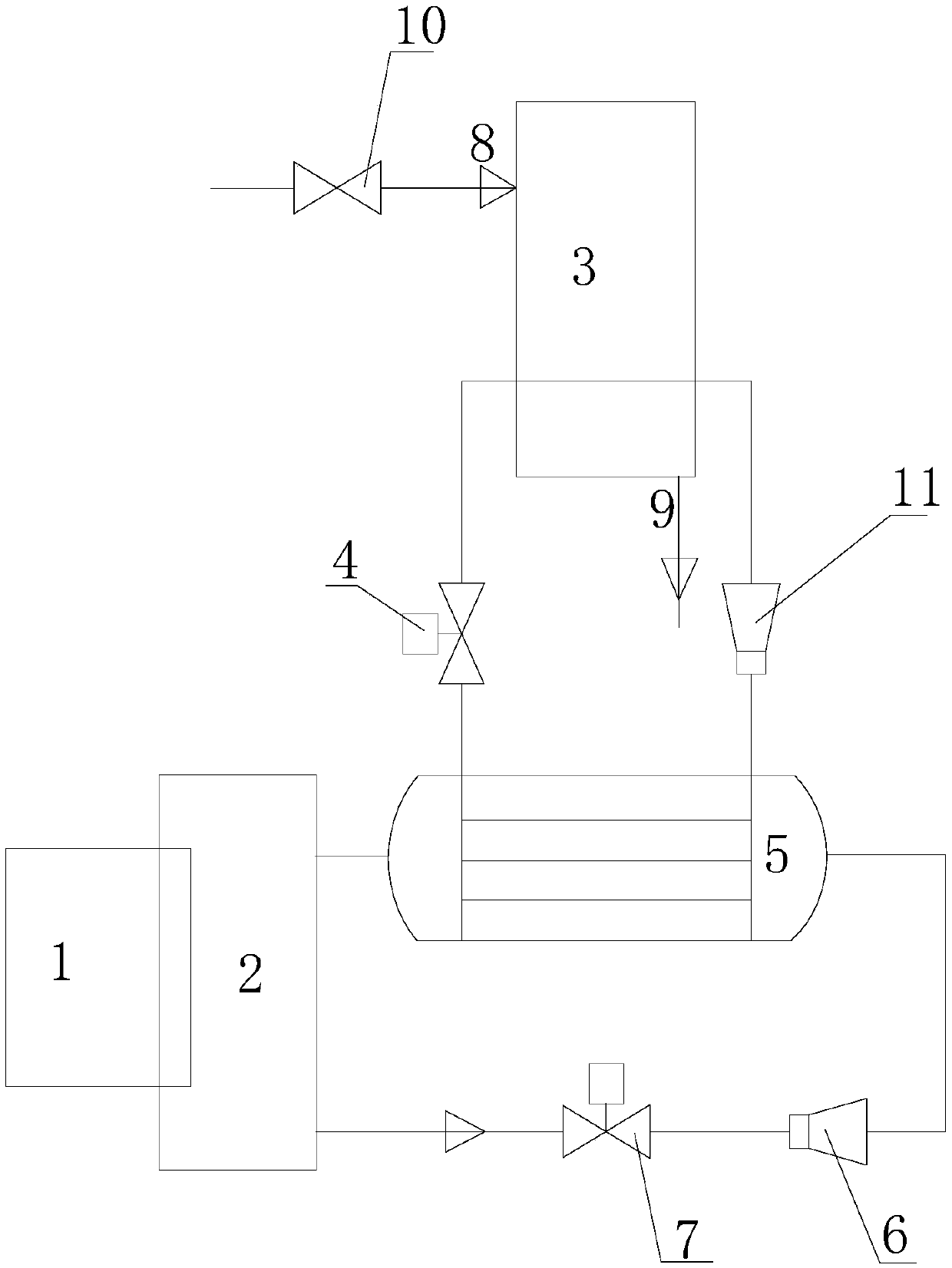

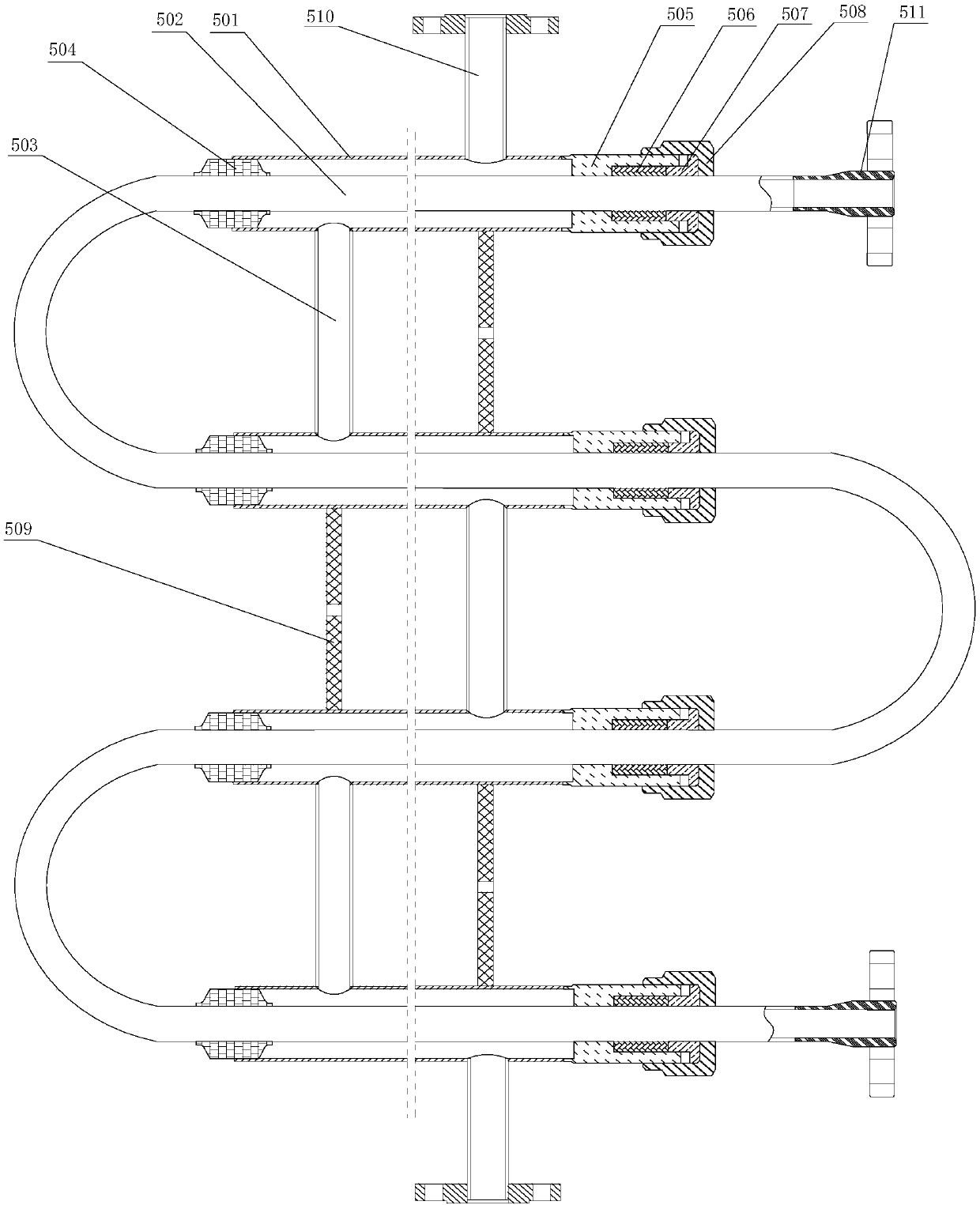

[0028] Such as Figures 1 to 2As shown, the test simulation device of the multi-loop coupled heat conduction passive waste discharge system of the present invention includes a reactor simulation body and a primary loop system 1, a passive waste heat discharge system, and a seawater system, wherein the reactor simulation body and the primary loop system include a reactor Core, steam generator, ascending section, hanging basket simulation piece, lower section of pressure vessel, middle section of pressure vessel, and upper section of pressure vessel. The hanging basket simulation piece is in the lower part of the pressure vessel. In the ascending section above the simulated part, the steam generator is evenly arranged in the annular cavity formed by the outer wall of the simulated part in the ascending section and the inner wall of the pressure vessel, which is used to simulate the thermodynamic state of the reactor in the shutdown or working condition accident state; the passive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com