Finite element-based pitch and tooth profile optimization method for 8M arc tooth synchronous belt

An optimization method and technology of timing belts, applied in design optimization/simulation, instrumentation, geometric CAD, etc., can solve problems such as low optimization efficiency, inaccurate contact stress calculation, and repeated production, so as to save R&D costs and reduce interference stress , The effect of saving the R & D cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

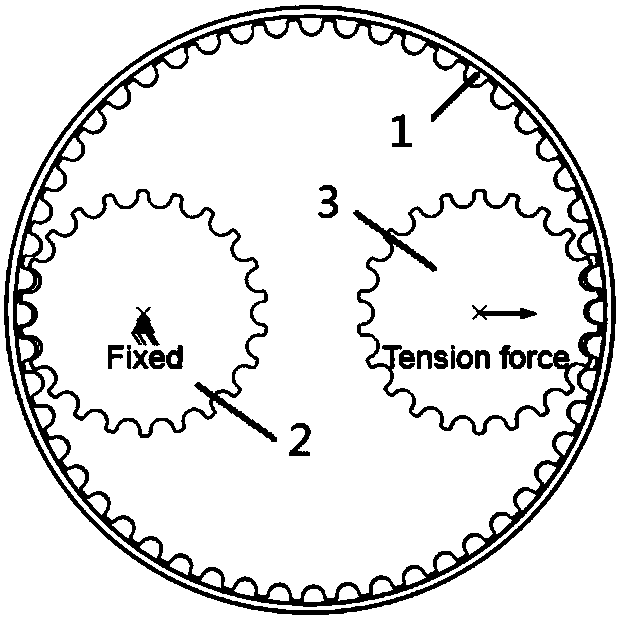

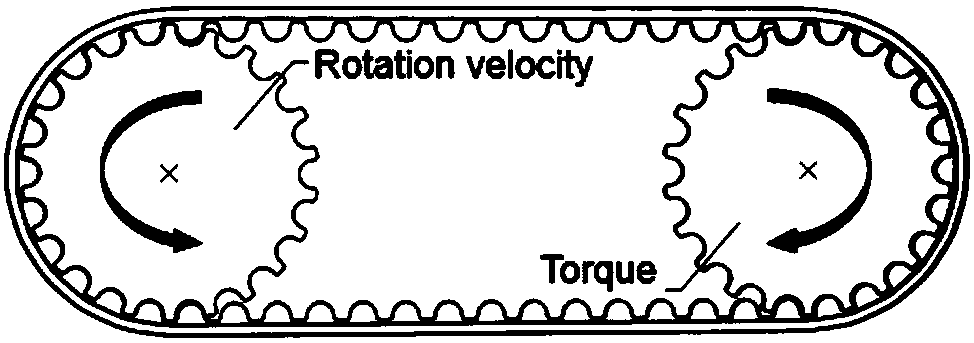

[0029] The implementation example of the present invention will be described in detail below with reference to the description of the triangular belt finite element model in conjunction with the accompanying drawings.

[0030] Build the synchronous belt and sprocket components separately, the 8M synchronous belt has 105 teeth, the width is 20mm, and the sprocket has 32 teeth.

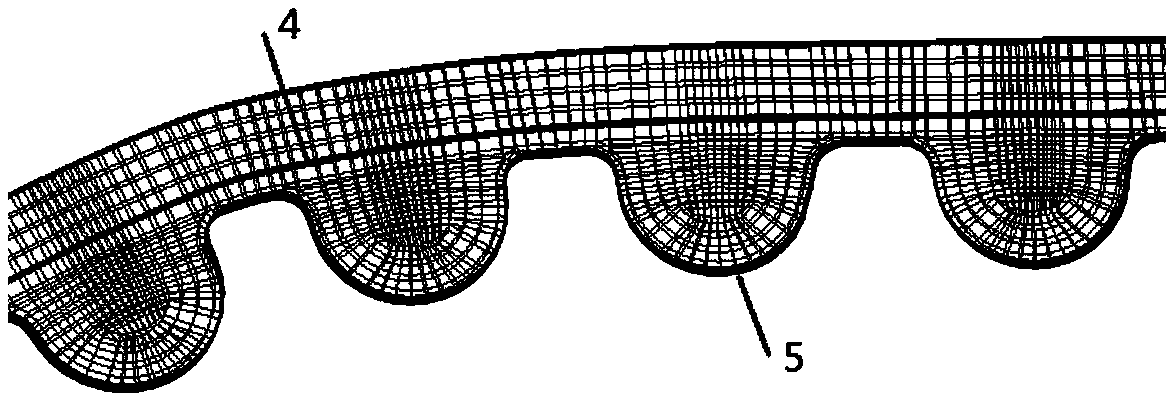

[0031] For the component division unit, the rubber part of the synchronous belt adopts a three-dimensional solid unit to assign the rubber material parameters of the synchronous belt model as shown in Table 1, and to assign the material parameters of the cord and elastic cloth of the synchronous belt, and use the REBAR unit to define the parameters of the cord and elastic cloth as shown in Table 2. The model components are assembled and the tooth-to-tooth contact is defined using a nodal-to-surface frictional contact algorithm based on the finite element large deformation equation. The contact friction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com