Preparation method of colloid probe for atomic force microscope

An atomic force microscope and probe technology, applied in the field of physics, can solve the problem of the cleanliness of the precision colloidal probe, the difficulty in guaranteeing the success rate and efficiency of processing, the difficulty in guaranteeing the visual imaging quality and motion control accuracy of personalized equipment, and measuring Accuracy and resolution impact and other issues, to achieve the effect of high success rate, guaranteed accuracy and precision, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

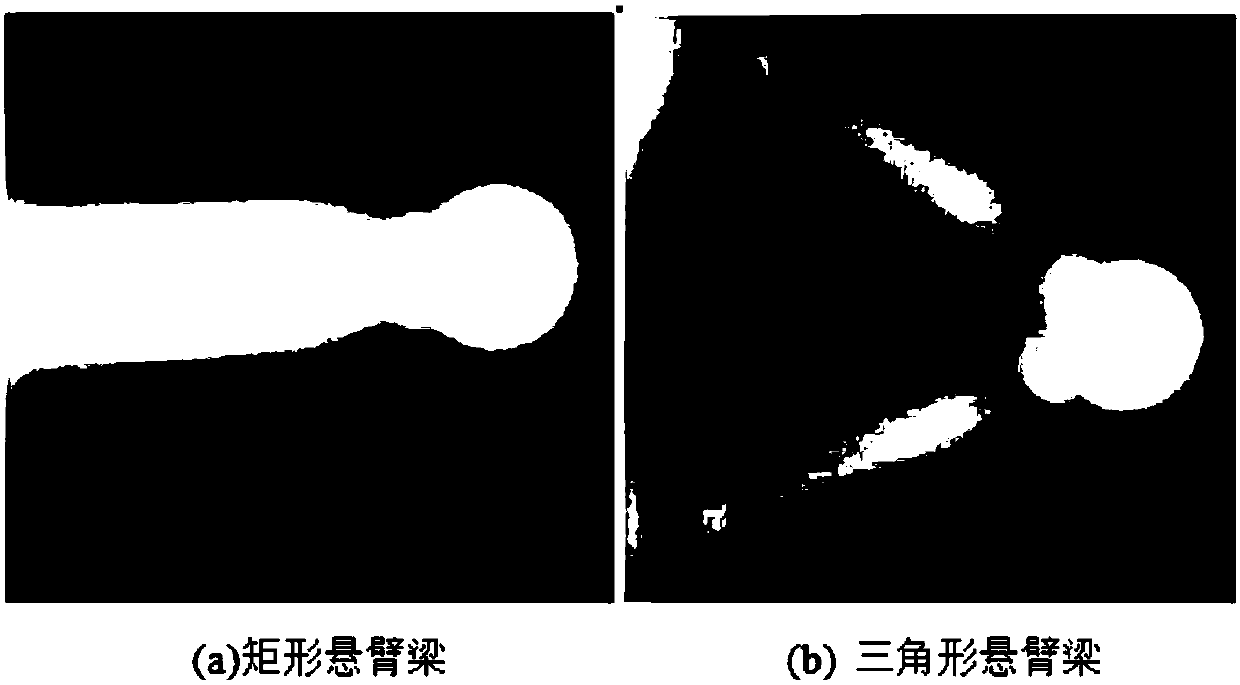

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and examples.

[0037] High borosilicate glass microspheres (GL018B / 45-33, MO-Sci Company) with a diameter of about 60 microns were ultrasonically cleaned with acetone and methanol for 5 minutes respectively, and the cleaned high borosilicate glass microspheres were placed in methanol solution and sealed Store for later use.

[0038] Cut the silicon wafer (Silicon Quest International) into small square pieces of about 1cm×1cm, and place the three cut square silicon wafers in acetone solution and isopropanol solution for 2-3 times of ultrasonic cleaning for 5 minutes. Finally, dry the cleaned silicon wafers with clean air to remove surface residues and ensure that the surface of the silicon wafers is clean for future use.

[0039] Gently shake the methanol solution containing the microspheres so that the microspheres are evenly distributed in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com