Pillow-shaped plate type heating radiator

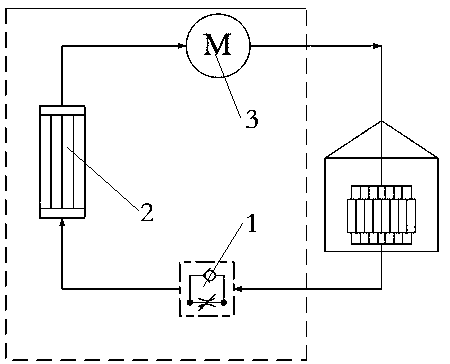

A technology of plate heat sinks and radiators, which is applied to the shell of heat exchangers, household heating, heating methods, etc., which can solve the problems of large footprint of radiators, increased installation costs, and long heating pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

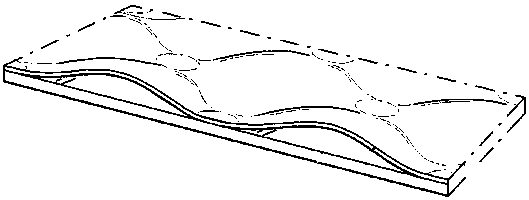

[0026] Such as Figure 4-Figure 5 As shown, at least two pillow-shaped plate heat sinks 4 are provided, and the pillow-shaped plate heat sink 4 adopts the first upper sealing plate 7, the lower second sealing plate 8, and the third sealing plate 9 on the left side. And the fourth sealing plate seal 10 on the right side is set to form a pillow-shaped plate heating radiator, and the pillow-shaped plate heat sink 4 is provided with a weld 11, and the upper or lower ends of the weld 11 are respectively arranged on the pillow-shaped plate heat sink. The upper end and the lower end of the heat sink 4 are arranged at intervals in sequence to form a continuous S-shaped refrigerant flow channel 12, and the refrigerant inlet 5 and the refrigerant outlet 6 are respectively arranged at the welding seam 11 of the pillow-shaped plate heat sink 4 closed end side.

[0027] The indoor pillow-shaped plate heating radiator is mainly composed of pillow-shaped plate heat sinks, upper, lower, left...

Embodiment 2

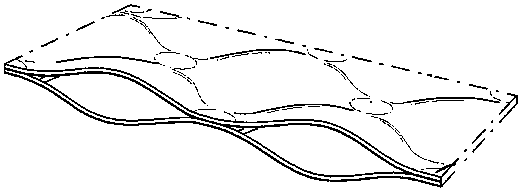

[0029] Such as Figure 6 As shown, the pillow-shaped plate heating radiator is composed of two metal flat plates 13 and a double-sided pillow-shaped heat sink arranged between the two metal plates 13. Sandwiched in the middle, the pillow-shaped plate heat sinks on both sides can also conduct heat conduction and heat dissipation through the metal plate. This structure not only beautifies the appearance of the heater but also does not affect the heat exchange.

Embodiment 3

[0031] Such as Figure 7 As shown, the pillow-shaped panel heating radiator is a continuously folded screen structure composed of a plurality of unilateral pillow-shaped plate radiators connected end to end. composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com