Preparation method of biodegradable hydrophobic envelope material

A coating material and biodegradable technology, which is applied in the field of preparation of biodegradable hydrophobic coating materials, can solve the problems of poor biodegradability, poor waterproof effect, and cannot meet the needs of crop growth, and achieves enhanced hydrophobicity, The effect of enhanced hydrophobicity and enhanced bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

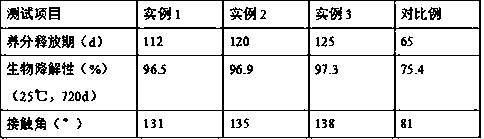

Examples

example 1

[0022]Mix the shrimp shells and crab shells in an equal mass ratio for 16 minutes to obtain a mixture, continue to add biogas slurry with a mass of 0.9% of the mixture to the mixture, put it into a fermenter, and seal it for fermentation at a temperature of 32°C for 7 days. After the end, take out the fermentation product, which is the chitosan-containing fermentation product, and then mix and stir pyridine and chloroform at a volume ratio of 1:1 for 4 minutes to obtain a self-made solution; The ratio is 1:3 and the mixture is placed in a beaker for 3 minutes to react, then continue to drop octanoyl chloride containing 10% chitosan fermentation product mass into the beaker in an ice bath at 0°C, and continue to mix and stir at a temperature of 55°C React for 1h, and after the reaction finishes, the crude product of acylated chitosan is obtained. The crude product of acylated chitosan is put into an extractor, extracted with acetone for 4 hours, and vacuum-dried for 1 hour to ob...

example 2

[0024] Stir the shrimp shells and crab shells in an equal mass ratio for 18 minutes to obtain a mixture, continue to add biogas slurry with a mass of 0.9% of the mixture to the mixture, put it into a fermenter, and ferment for 8 days under the condition of a temperature of 37°C. After the end, take out the fermentation product, which is the chitosan-containing fermentation product, and then mix and stir pyridine and chloroform at a volume ratio of 1:1 for 5 minutes to obtain a self-made solution; Mix and place in a beaker for 4 minutes at a ratio of 1:3, then continue to drop octanoyl chloride containing 10% chitosan fermentation product mass into the beaker in an ice bath at 0°C, and continue to mix and stir at a temperature of 65°C React for 1.5h. After the reaction, the crude product of acylated chitosan is obtained. Put the crude product of acylated chitosan into an extractor, extract it with acetone for 5 hours, and dry it in vacuum for 2 hours to obtain acylated chitosan ...

example 3

[0026] Mix shrimp shells and crab shells in an equal mass ratio for 20 minutes to obtain a mixture, continue to add biogas slurry with a mass of 0.9% of the mixture to the mixture, put it into a fermenter, and seal and ferment for 9 days at a temperature of 42°C. After the end, take out the fermentation product, which is the chitosan-containing fermentation product, and then mix and stir pyridine and chloroform at a volume ratio of 1:1 for 6 minutes to obtain a self-made solution; The ratio is 1:3, mix and place in a beaker for 5 minutes to react, then continue to drop octanoyl chloride containing 10% chitosan fermentation product mass into the beaker under the condition of ice bath at 0°C, and continue to mix and stir at a temperature of 75°C Reaction for 2h, the acylated chitosan crude product is obtained after the reaction is completed, the acylated chitosan crude product is put into an extractor, extracted with acetone for 6h, and vacuum-dried for 3h to obtain the acylated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com