Synthesis method of titanium silicon molecular sieve ts-1 for catalytic hydrogen peroxide oxidation reaction

A titanium-silicon molecular sieve, TS-1 technology, applied in molecular sieve catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of complex precursor solution process, long cycle, different material properties, etc., and shorten the crystallization time. , reduce usage, optimize the effect of synthesis conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

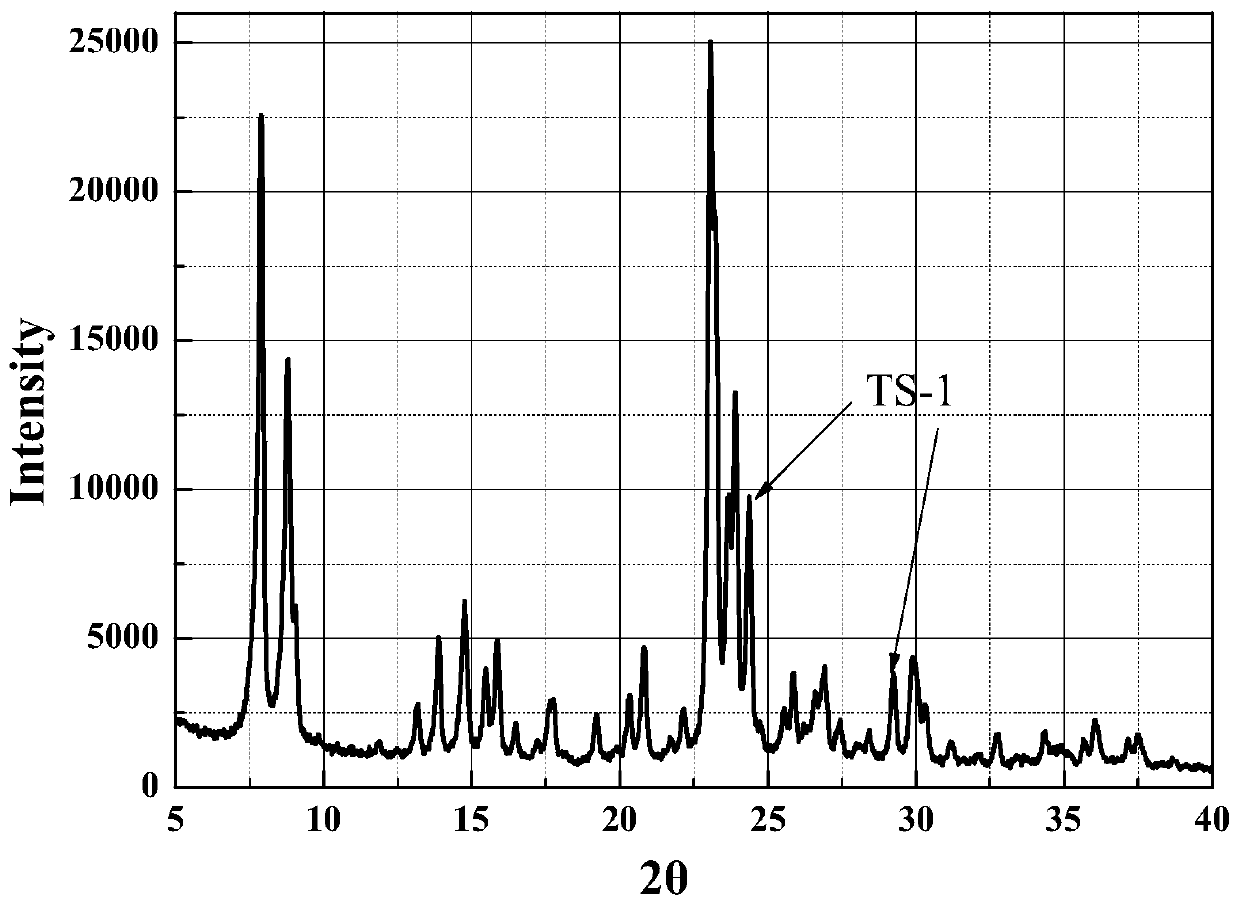

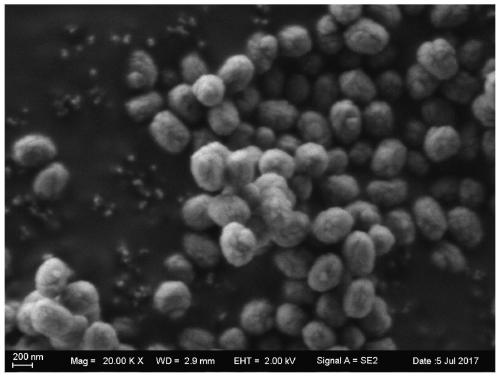

[0070] Weigh and weigh 50.0g ethyl orthosilicate and 2.5g tetrabutyl titanate at room temperature, after mixing uniformly, add 73.2g tetrapropyl ammonium hydroxide solution (12.5wt%), dropwise Keep stirring vigorously to obtain a clear and transparent solution, continue to hydrolyze for 1.5 h, and wash alcohol at 75 ° C for 2 h to obtain a light yellow sol. Take a certain amount of ammonium fluoride solid, dissolve it in concentrated ammonia water (30wt%) to form an ammonia solution of ammonium fluoride, and add this solution dropwise to the light yellow sol, continue stirring evenly, and add water again to make the mother liquor SiO by molar ratio 2 :TiO 2 :TPAOH:H 2 O:F - =1:0.03:0.17:20:0.12. Then crystallize at 170°C for 24h, and cool down to room temperature. After the obtained crystallization solution was centrifuged, the filter cake was washed until neutral, spray-dried, and calcined at 550° C. for 3 hours to obtain titanium-silicon molecular sieve TS-1F. Its XRD ...

Embodiment 2

[0074] Weigh 50.0 g of tetrabutyl titanate and 50.0 g of tetrabutyl titanate at room temperature, and mix them uniformly. Dissolve a certain amount of ammonium fluoride in concentrated ammonia water (30wt%) to form an ammonia solution of ammonium fluoride, and add this solution dropwise to the mixed solution of titanium source and silicon source, after stirring evenly, add 10g, 25wt% Hydrogen peroxide, continue to stir, then add 73.2g tetrapropyl ammonium hydroxide solution (12.5wt%), keep stirring vigorously during the dropwise addition. Hydrolyzed for 1.5h, followed by alcohol at 75°C for 2h to obtain light yellow sol. Add water again, so that the mother liquor is calculated as SiO according to the molar ratio 2 :TiO2 :TPAOH:H 2 O:F - =1:0.03:0.17:20:0.1. Then it was crystallized under hydrothermal conditions at 170°C for 24h, and cooled down to room temperature. After the obtained crystallization solution was centrifuged, the filter cake was washed until neutral, spray...

Embodiment 3

[0076] Weigh 50.0g ethyl orthosilicate and 2.5g tetrabutyl titanate under ice-water bath conditions, after mixing evenly, add 73.2g tetrapropyl ammonium hydroxide solution (12.5wt%), keep vigorous After stirring to obtain a clear and transparent solution, continue to hydrolyze for 3 hours, and chase alcohol at 75°C for 2 hours to obtain a light yellow sol. Dissolve a certain amount of ammonium fluoride in aqueous ammonia (15wt%) to form an aqueous ammonia solution of ammonium fluoride, add this solution dropwise into the light yellow sol, and after stirring evenly, add water again so that the mother liquor is calculated according to the molar ratio. SiO 2 :TiO 2 :TPAOH:H 2 O:F - =1:0.03:0.17:20:0.27. Then crystallize at 180°C for 24h, and cool down to room temperature. After the obtained crystallization solution was centrifuged, the filter cake was washed until neutral, spray-dried, and finally calcined at 550° C. for 3 hours to obtain titanium-silicon molecular sieve TS-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com