Internal heating type molecular distillation device

A molecular distillation and internal heating technology, applied in the field of machinery and equipment, can solve problems such as short time, usually only ten seconds to a few minutes, complicated manufacturing and maintenance, and complicated manufacturing process, so as to achieve low equipment manufacturing and operation maintenance costs, and low production costs. Low cost, good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

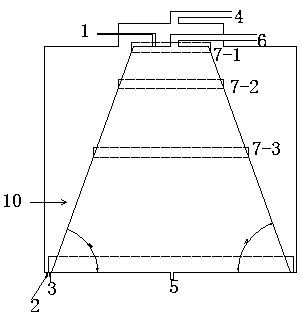

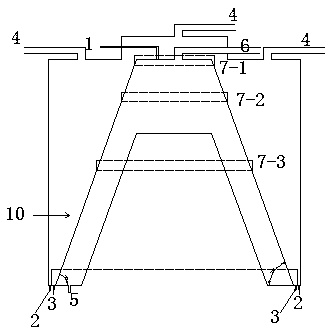

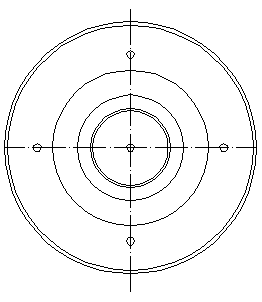

[0033] It includes a molecular distillation equipment body 10 and a vacuum tube 4. The heater inside the molecular distillation equipment body 10 is in the shape of a circular platform. The angle formed by the intersection of the two busbars opposite to the circular platform and the lower bottom line can be 2 degrees to less than 90 degrees, that is, the angle of the circular platform. The bottom angle can be 2 degrees to less than 90 degrees, preferably 30 degrees to less than 90 degrees; the external sealing device is a sealing body, the top of the sealing body is connected to the top head, the top head is connected to the material inlet pipe 1, and the heater There are multiple material distributors on the round table. The heater round table is installed at the bottom of the sealing body or the bottom of the heater round table is a part of the bottom of the sealing body; the vacuum tube 4 is arranged on the top end of the sealing body, and the vacuum tube 4 communicates with...

Embodiment 2

[0037]It includes a molecular distillation equipment body 10 and a vacuum tube 4. The heater inside the molecular distillation equipment body 10 is in the shape of a circular platform. The angle formed by the intersection of the two busbars opposite to the circular platform and the lower bottom line can be 2 degrees to less than 90 degrees, that is, the angle of the circular platform. The bottom angle can be 2 degrees to less than 90 degrees, preferably 30 degrees to less than 90 degrees; the external sealing device is a sealing body, the top of the sealing body is connected to the top head, the top head is connected to the material inlet pipe 1, and the heater There are multiple material distributors on the round table. A partial hollow structure is arranged inside the heater round platform, such as a round platform-shaped hollow or two or more adjacent terrace-shaped hollow structures. The heater round platform is installed on the bottom of the sealing body or the bottom of ...

Embodiment 3

[0043] It includes a molecular distillation equipment body 10 and a vacuum tube 4. The heater inside the molecular distillation equipment body 10 is in the shape of a circular platform. The angle formed by the intersection of the two busbars opposite to the circular platform and the lower bottom line can be 2 degrees to less than 90 degrees, that is, the angle of the circular platform. The bottom angle can be 2 degrees-less than 90 degrees; preferably 30 degrees-less than 90 degrees; the external sealing device is a sealing body, and the body wall of the sealing body is a water-cooled jacket device. There is a cooling water outlet 9; the top of the sealing body is connected to the top head, the top head is connected to the material inlet pipe 1, and there are multiple material distributors on the heater round table. A partial hollow structure is arranged inside the heater round platform, such as a round platform-shaped hollow or two or more adjacent terrace-shaped hollow struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com