Horizontal well completion pipe string for middle-shallow oil reservoir

A technology for well completion strings and horizontal wells, which is applied in wellbore/well components, wellbore/well valve devices, earthwork drilling and production, etc., and can solve delays in construction progress, stuck in wellbore, large casing strings, etc. problem, to achieve the effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

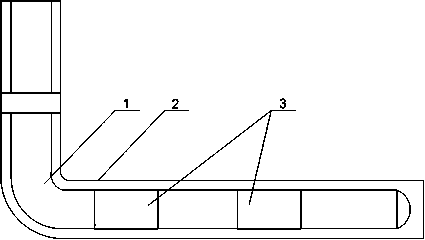

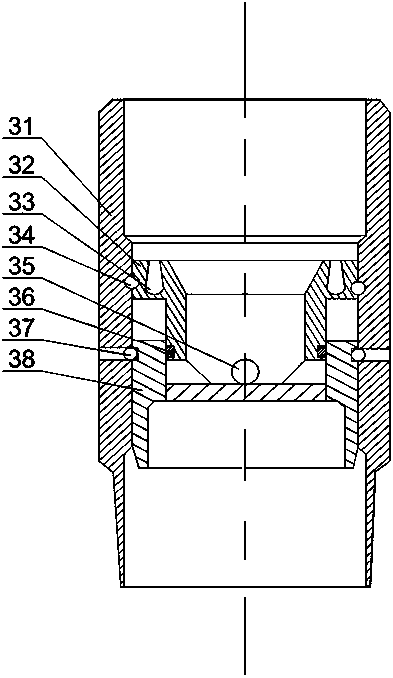

[0022] like figure 1 and figure 2 As shown, this embodiment includes a casing 1 placed in the wellbore 2, and two floating collars 3 are arranged on the horizontal section of the casing 1, and the floating collars 3 include a casing 31, an upper sliding Sleeve 32 and sliding sleeve 38, the upper sliding sleeve 32 is composed of interconnecting parts and a shearing part with the same outer diameter as the inner diameter of the housing 31, the shearing part is supported on the upper section of the inner wall of the housing 31 by the upper shear nail 34, and slides down The sleeve 38 is supported on the lower section of the inner wall of the housing 31 by the lower shear nail 37. The communication part is placed in the lower sleeve 38, and a discharge hole 35 is opened on the communication part. When the upper shear nail 34 is not cut off, The lower sleeve 38 seals the discharge hole 35, and when the upper shear nail 34 is cut off, the upper sliding sleeve 32 moves along the ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com