Preparation method of light sensation shell fabric

A fabric and light-sensing technology, applied in the direction of dyeing, dry-cleaning fiber products, fabric surface trimming, etc., can solve the problems of affecting the light-changing performance, damage, weakening of the light-sensing effect, etc., and achieve strong tear resistance and fracture resistance. , Excellent washing resistance and water resistance, the effect of enhancing photochromic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

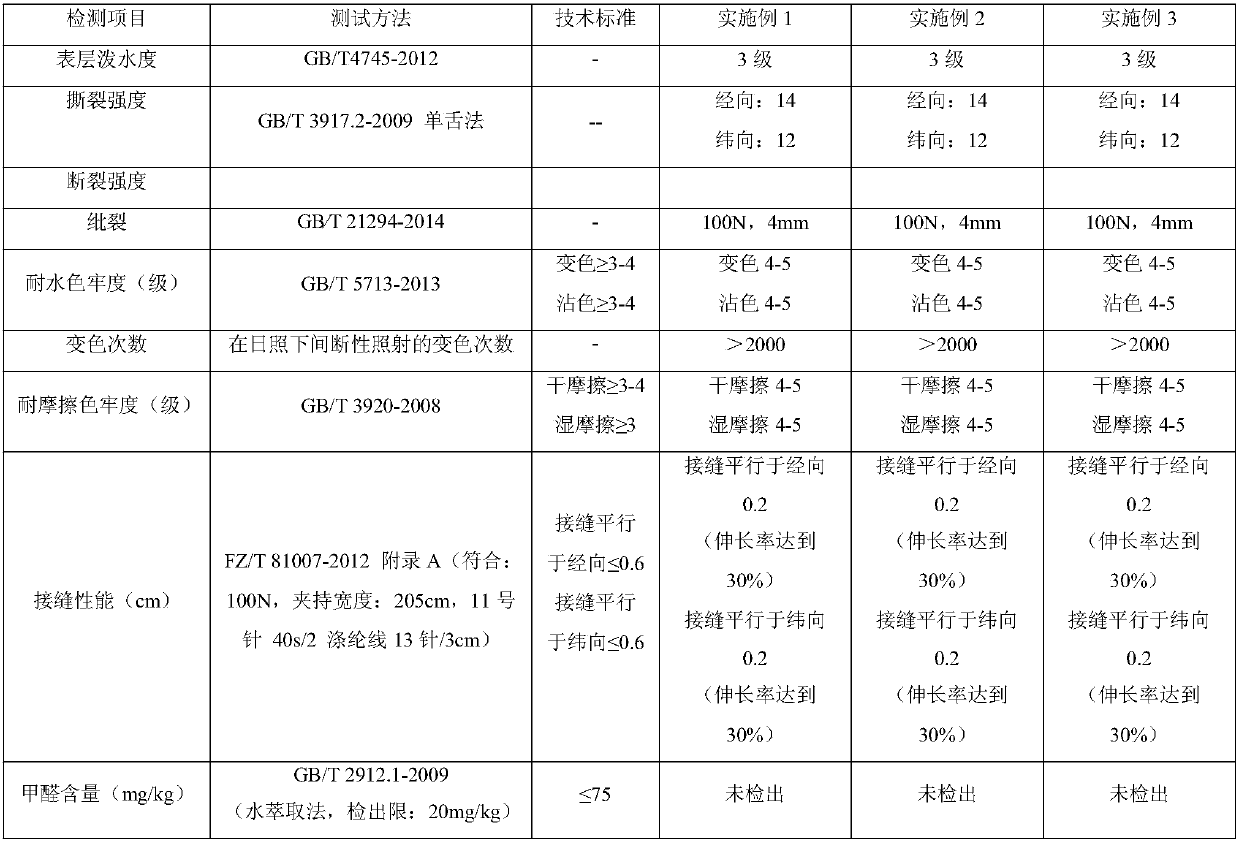

Examples

Embodiment 1

[0051] The preparation method of photosensitive fabric comprises the following steps:

[0052] Step 1, weaving and warping:

[0053] The nylon warp yarn is warped by a warping machine to obtain a matte nylon warp thread, wherein the matte nylon is a matte nylon with a twist of 400T and a fineness of 18D.

[0054] Step 2, pulp:

[0055] The warp yarn obtained in step 1 is subjected to sizing treatment to obtain nylon sizing yarn, wherein the sizing treatment uses sizing material WJ-98.

[0056] Step 3, combined with:

[0057] The nylon sizing obtained in step 2 is paralleled by a machine to obtain parallelized nylon.

[0058] Step four, weaving:

[0059] Put the gained in step 3 on the water-jet loom for weaving through nylon to obtain nylon gray cloth, wherein the water-spray angle of the water-jet loom is 8 degrees, and the weft density of the upper machine is 180T.

[0060] Step 5. Gray fabric inspection and desizing:

[0061]Inspect the nylon gray cloth obtained in st...

Embodiment 2

[0078] The preparation method of photosensitive fabric comprises the following steps:

[0079] Step 1, weaving and warping:

[0080] Nylon warp yarns are warped by a warping machine to obtain matte nylon warp threads, wherein the matte nylon is twist 420T, matte nylon with a fineness of 20D;

[0081] Step 2, pulp:

[0082] Sizing the warp yarn obtained in step 1 to obtain nylon sizing, wherein the sizing process uses size WJ-98;

[0083] Step 3, combined with:

[0084] Step 2 gained nylon sizing is paralleled by a machine to obtain parallelized nylon;

[0085] Step four, weaving:

[0086] Weave the cloth obtained in step 3 on a water-jet loom through nylon to obtain a nylon gray cloth, wherein the water-spray angle of the water-jet loom is 10 degrees, and the weft density of the upper machine is 185T;

[0087] Step 5. Gray fabric inspection and desizing:

[0088] Desizing the nylon gray cloth obtained in step 4 to obtain a desizing gray cloth, wherein the desizing aid in...

Embodiment 3

[0106] The preparation method of photosensitive fabric comprises the following steps:

[0107] Step 1, weaving and warping:

[0108] Nylon warp yarns are warped by a warping machine to obtain matte nylon warp threads, wherein the matte nylon is twist 430T, matte nylon with a fineness of 22D;

[0109] Step 2, pulp:

[0110] Sizing the warp yarn obtained in step 1 to obtain nylon sizing, wherein the sizing process uses size WJ-98;

[0111] Step 3, combined with:

[0112] Step 2 gained nylon sizing is paralleled by a machine to obtain parallelized nylon;

[0113] Step four, weaving:

[0114] Weave the cloth obtained in step 3 on a water-jet loom through nylon to obtain a nylon gray cloth, wherein the water-spray angle of the water-jet loom is 9 degrees, and the weft density of the upper machine is 190T;

[0115] Step 5. Gray fabric inspection and desizing:

[0116] Desizing the nylon gray cloth obtained in step 4 to obtain a desizing gray cloth, wherein the desizing aid inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com