Sewage pretreatment device

A sewage pretreatment and equipment technology, applied in water/sewage treatment equipment, water/sewage treatment, biological water/sewage treatment, etc., can solve the problems of incomplete separation of sand and water, complex structure of sand filter, high cost, etc., to achieve clean The effects of long slag interval, small floor space and easy operation and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in combination with the accompanying drawings, and specific implementation methods will be given.

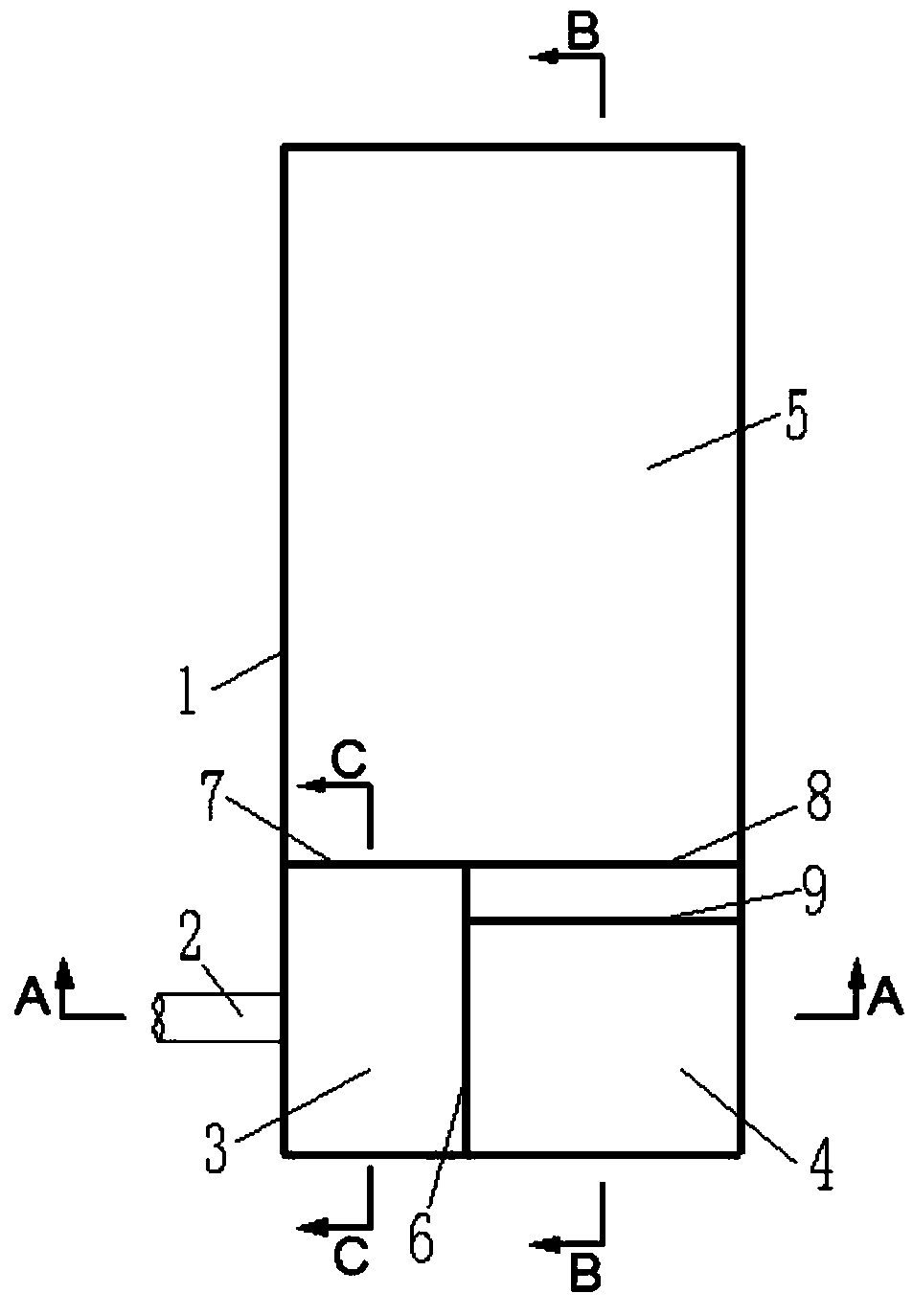

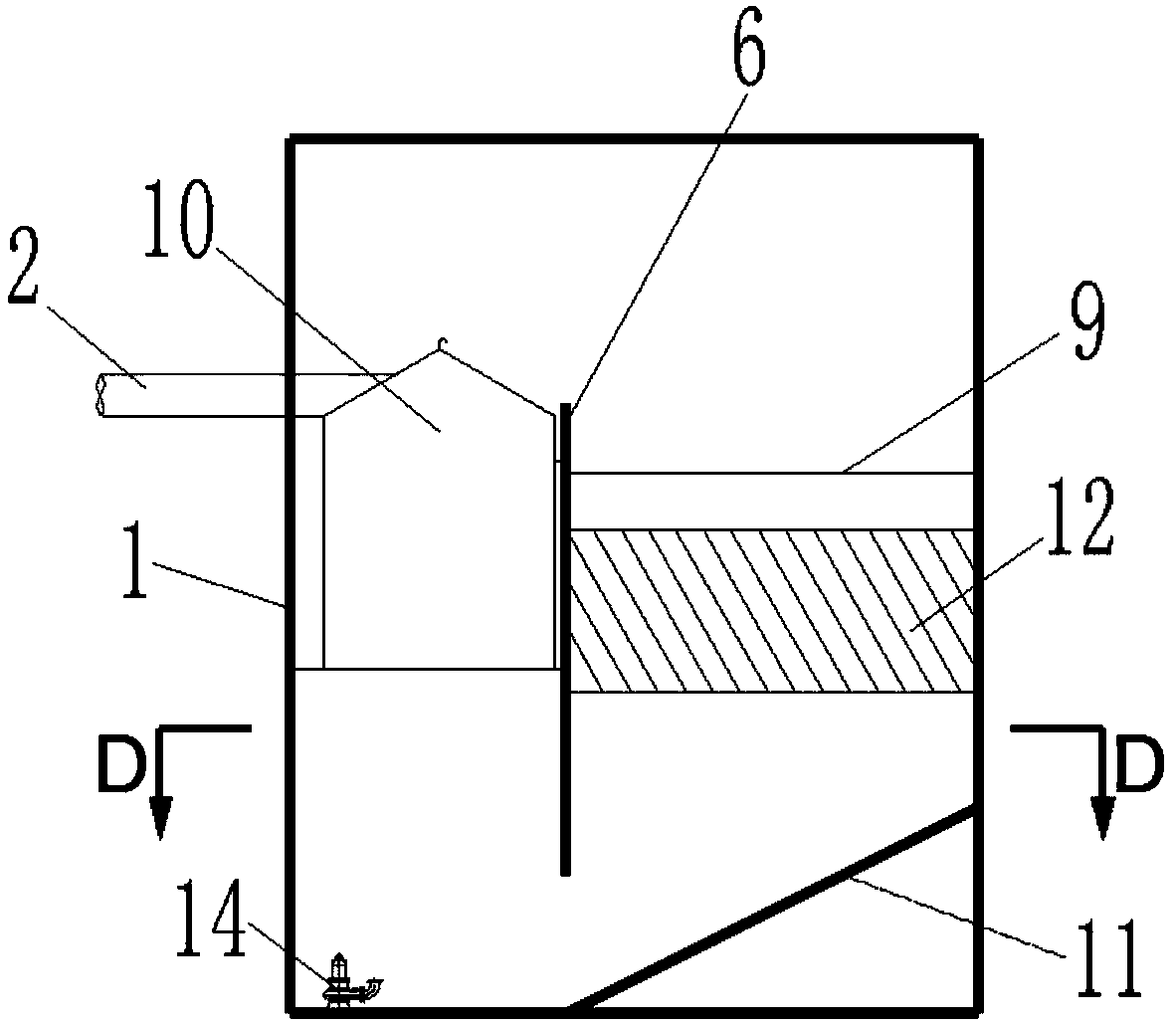

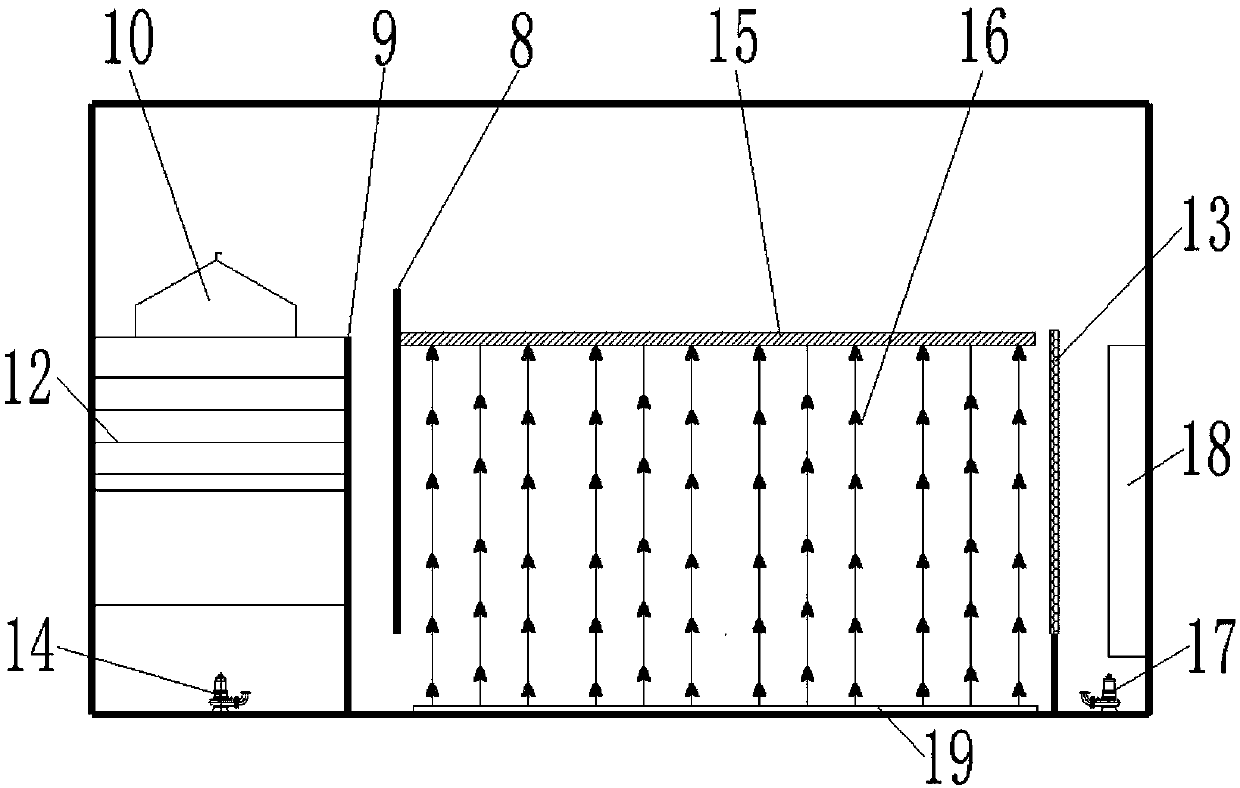

[0018] like Figure 1-5 As shown, a sewage pretreatment device includes a device body 1. The device body 1 is composed of a slag removal chamber 3, a sedimentation phosphorus removal chamber 4 and a hydrolysis adjustment chamber 5. The slag removal chamber 3 is composed of the inner wall of the device body 1, the first baffle 6 and the third baffle 7; the precipitation dephosphorization chamber 4 is surrounded by the inner wall of the equipment body 1, the first baffle 6 and the second baffle 8; the hydrolysis adjustment chamber 5 is surrounded by the inner wall of the equipment body 1, the third baffle 7 Surrounded by the second baffle plate 8; there is a gap between the bottom of the first baffle plate 6 and the bottom of the equipment body 1; there is a gap between the bottom of the second baffle plate 8 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com