Rapid design method of progressive die for auto-body sheet metal parts

A design method and technology for sheet metal parts, applied in the field of metal stamping, can solve problems such as affecting the efficiency of product production, restricting the level of stamping technology, and increasing the cost of stamping equipment, so as to avoid scrap, reduce mold debugging time, and shorten development. effect of cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

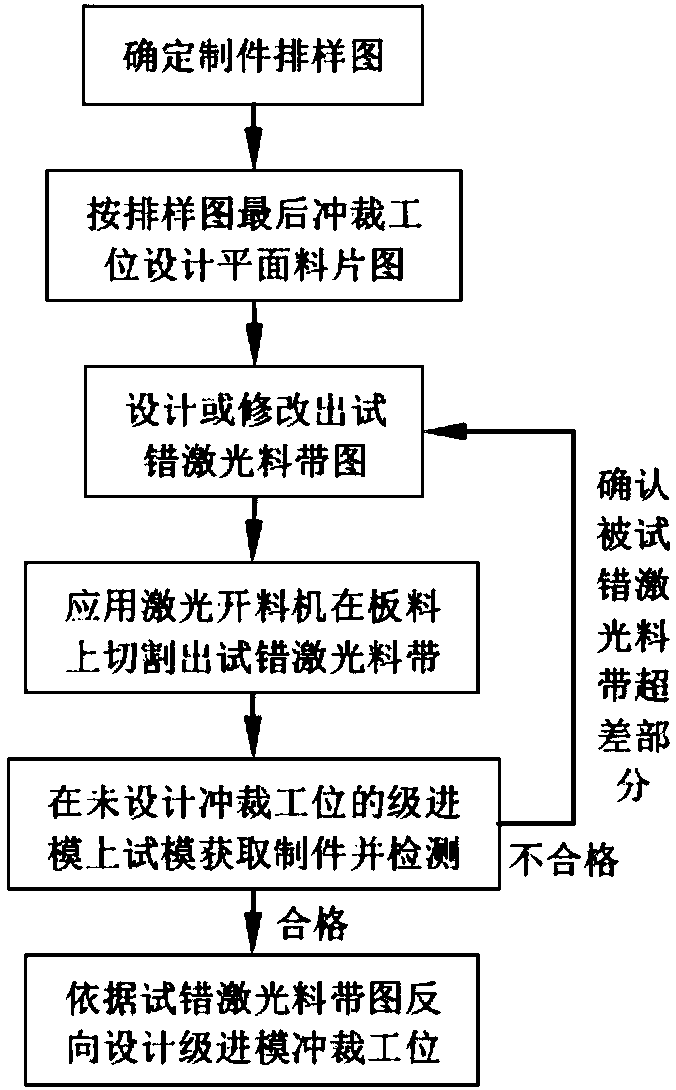

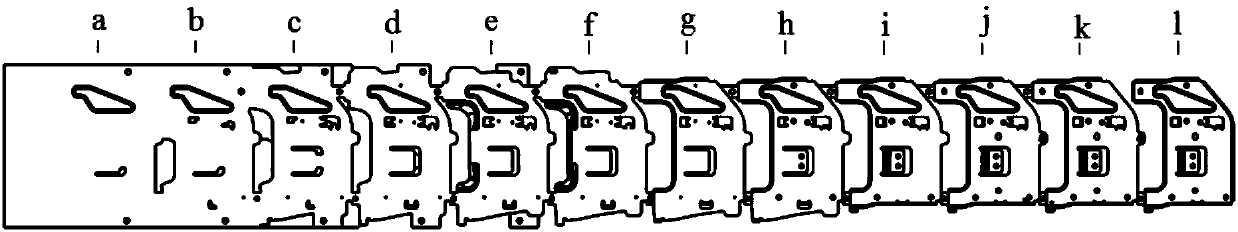

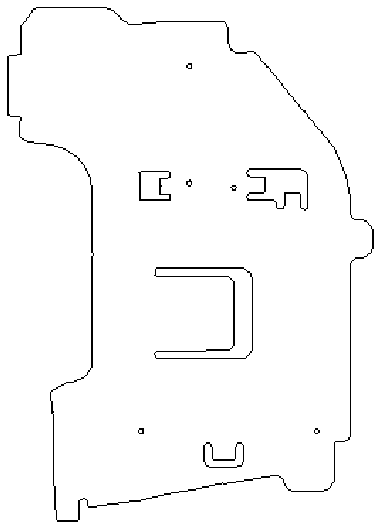

[0052] Such as figure 1 As shown, the present invention provides a method for rapid design of progressive dies for body sheet metal parts, comprising the following steps:

[0053] S1. By using the trial-and-error laser tape to test the mold, obtain the final trial punched part;

[0054] S2. Reversely design the punching station according to the final trial punched part.

[0055] Specifically, in step S1, the number of mold trials is at least one. In step S1, one mold trial may be performed, or multiple mold trials may be performed until a qualified trial stamped part is obtained, which is the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com