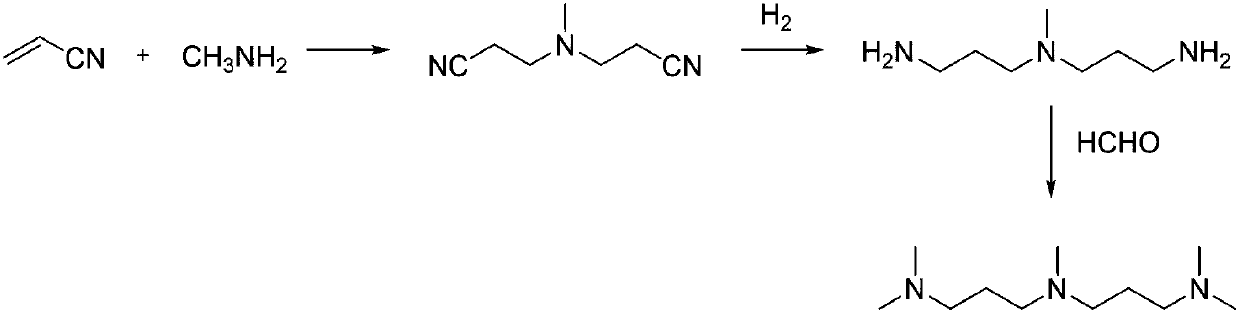

Metal supported MOFs catalyst as well as preparation method and application thereof to PMDPTA synthesis

A catalyst and metal technology, applied in the field of metal-loaded MOFs catalyst and its preparation, can solve the problems of complex and difficult synthesis process, easy oxidation and storage, etc., and achieve the effect of simple preparation method, low cost, and green production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Dissolve 0.016g of palladium chloride in 5mL of acetone to prepare a homogeneous palladium chloride in acetone solution; add the solution dropwise to 10g of activated MIL-101 and disperse it in 50mL of acetone, stir at room temperature for 24h, and filter to obtain the precursor; body placed in a quartz boat, in H 2 0.1%Pd / MIL-101 catalyst was obtained after reduction under atmosphere for 2h.

Embodiment 2

[0032] N,N-bis(2-cyanoethyl)methylamine (30mL), ethanol (150mL), sodium hydroxide (0.18g) and the catalyst (6g) prepared in Example 1 were added in a 300mL autoclave, and the After the kettle is sealed, the air in the kettle is replaced with nitrogen, three times and then replaced with hydrogen three times. The reaction mixture was reacted at a pressure of 2.0 MPa, a rotational speed of 500 rpm and a temperature of 90° C. for 6 h, and the reaction was stopped. After cooling down to room temperature, the mixture was suction-filtered, and the filtrate was concentrated to obtain 13.5 g of N,N-bis(3-aminopropyl)methylamine, with a yield of 45.0%.

[0033] N,N-bis(3-aminopropyl)methylamine (14.5g), methanol (150mL), formaldehyde solution (40.6g) and the catalyst (3g) prepared in Example 1 were added in a 300mL autoclave, and the After the kettle is sealed, the air in the kettle is replaced with nitrogen, three times and then replaced with hydrogen three times. The reaction mixtur...

Embodiment 3

[0035] Dissolve 0.16 palladium nitrate in 25 mL of acetone to prepare a homogeneous palladium nitrate in acetone solution; add the solution dropwise to 10 g of activated MIL-101 and disperse it in 50 mL of acetone, stir at room temperature for 24 hours, and filter to obtain the precursor; place the precursor in Quartz boat, the H 2 1%Pd / MIL-101 catalyst was obtained after reduction under atmosphere for 2h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com