Mixed gas ignition diffusing device

A technology of mixing gas and gas, applied to gas fuel burners, combustion methods, combustion types, etc., can solve the problems of complex tower structure, high ignition failure rate, and large operating noise, so as to reduce the number of configurations and simplify the tower Structural, balanced effects of pressure fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

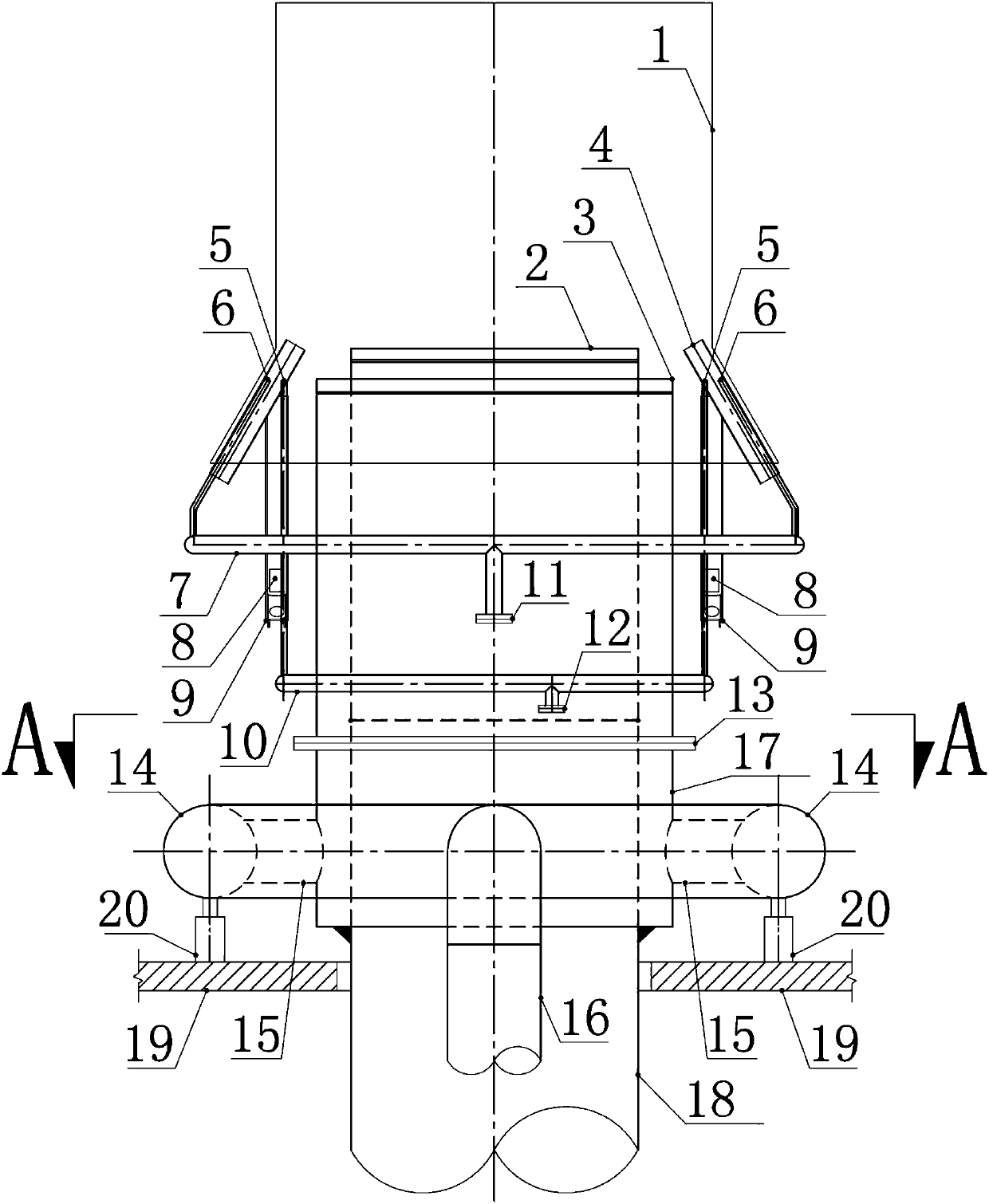

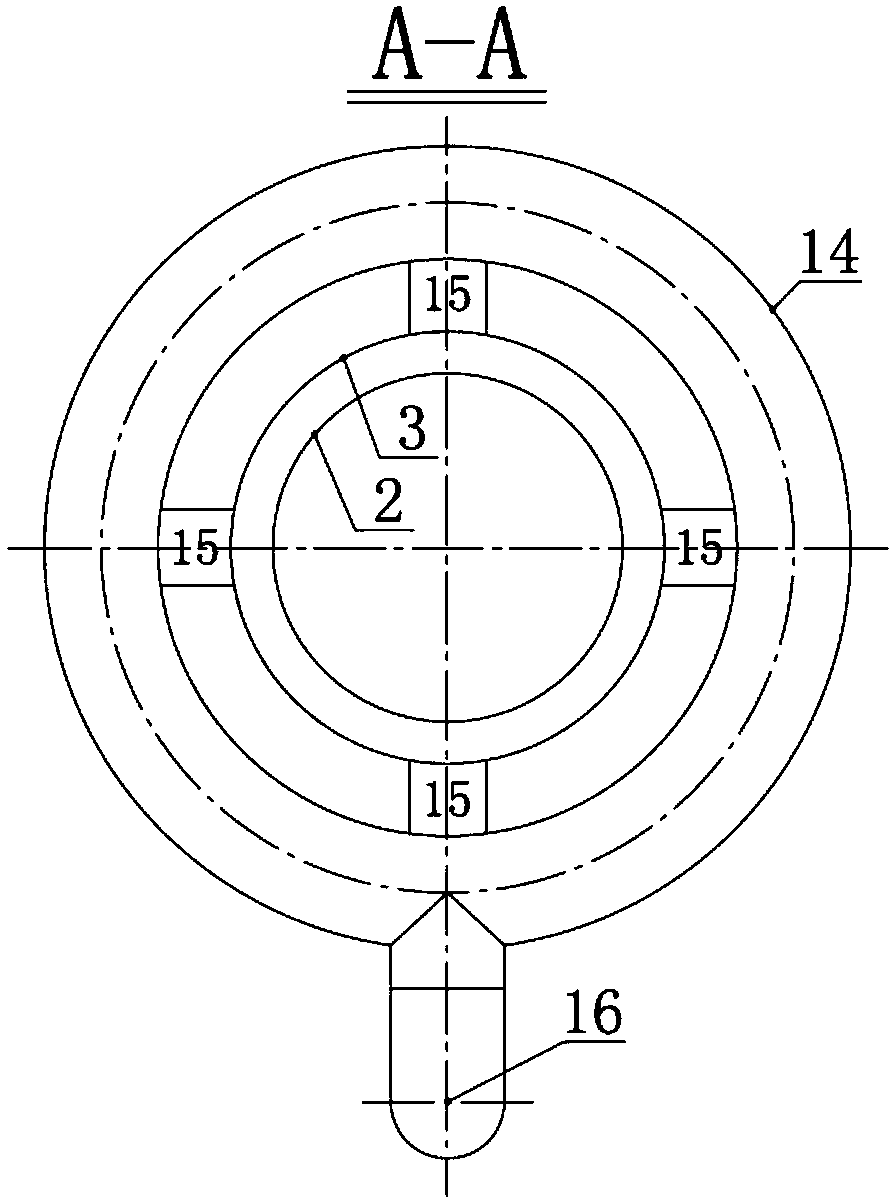

[0026] The patent will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the patent and implement it, but the examples given are not intended to limit the patent.

[0027] like figure 1 , figure 2 As shown, a mixed gas ignition and dispersing device includes an ignition gas ring pipe 7, an ignition gas ring pipe 10, an ignition burner 4, an outer swirl gas ring pipe 14, a high-altitude igniter 9, an outer swirl sheet 3, an inner swirl The flow sheet 2, the windproof outer cover 1, the bottom sleeve 17 of the torch head, the flange 13 connecting the outer swirl sheet 3, etc. The inner swirl sheet 2 is ignited and diffused as gas ①, and the gas ignited and diffused between the outer wall of the inner swirl sheet 2 and the inner wall of the outer swirl sheet 3 is outer swirl gas ②.

[0028] Inner swirl gas connecting pipe 18 connects from mixed gas release tower tower frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com