L-shaped concrete retaining wall

A technology for concrete and retaining walls, applied in the field of building materials, can solve the problems such as the inability to reuse the formwork, multi-site construction personnel, and the threat of the stability of the retaining wall, so as to reduce the sudden rise of the groundwater level, the connection effect is good, and the structural design is ingenious. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

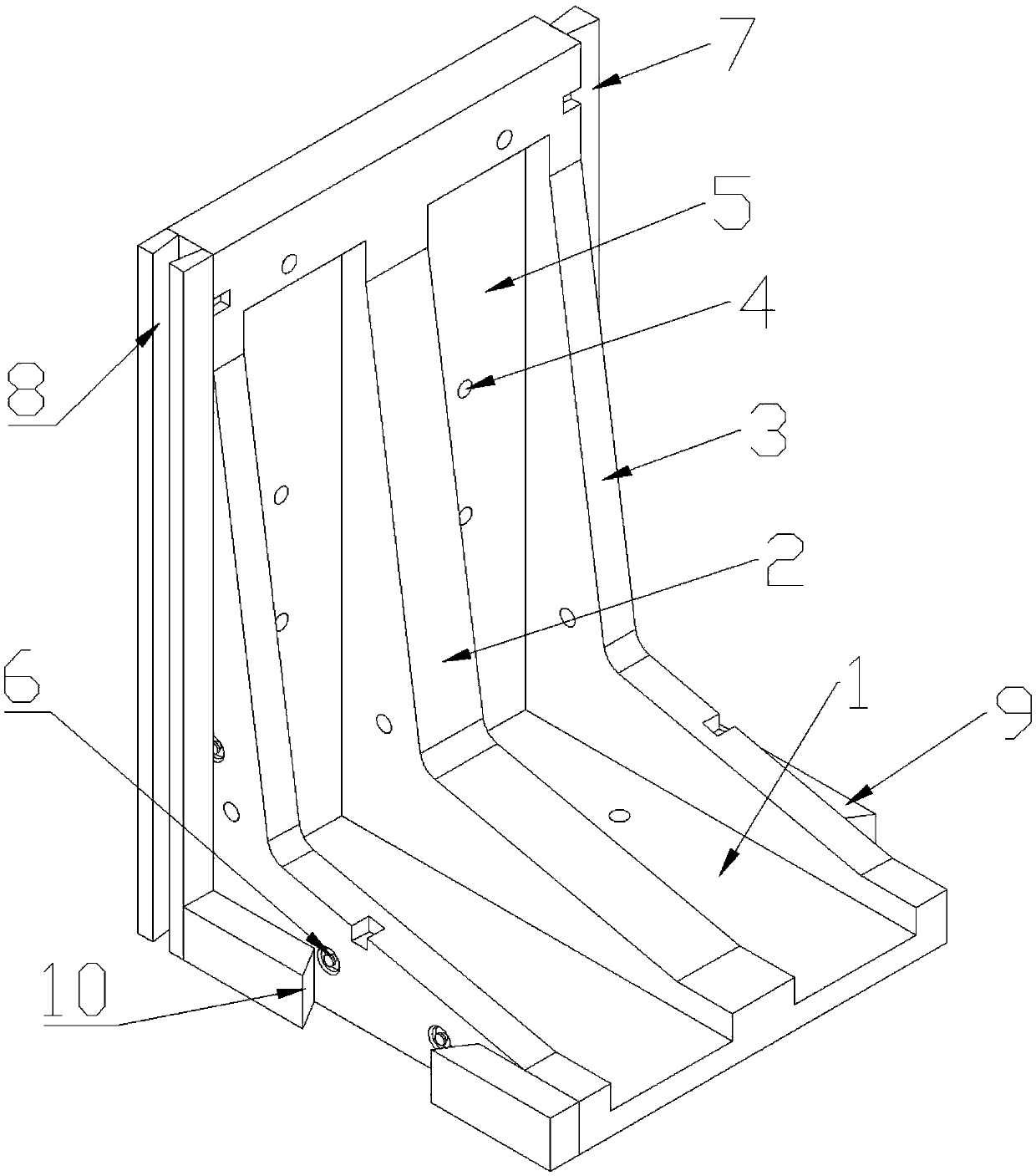

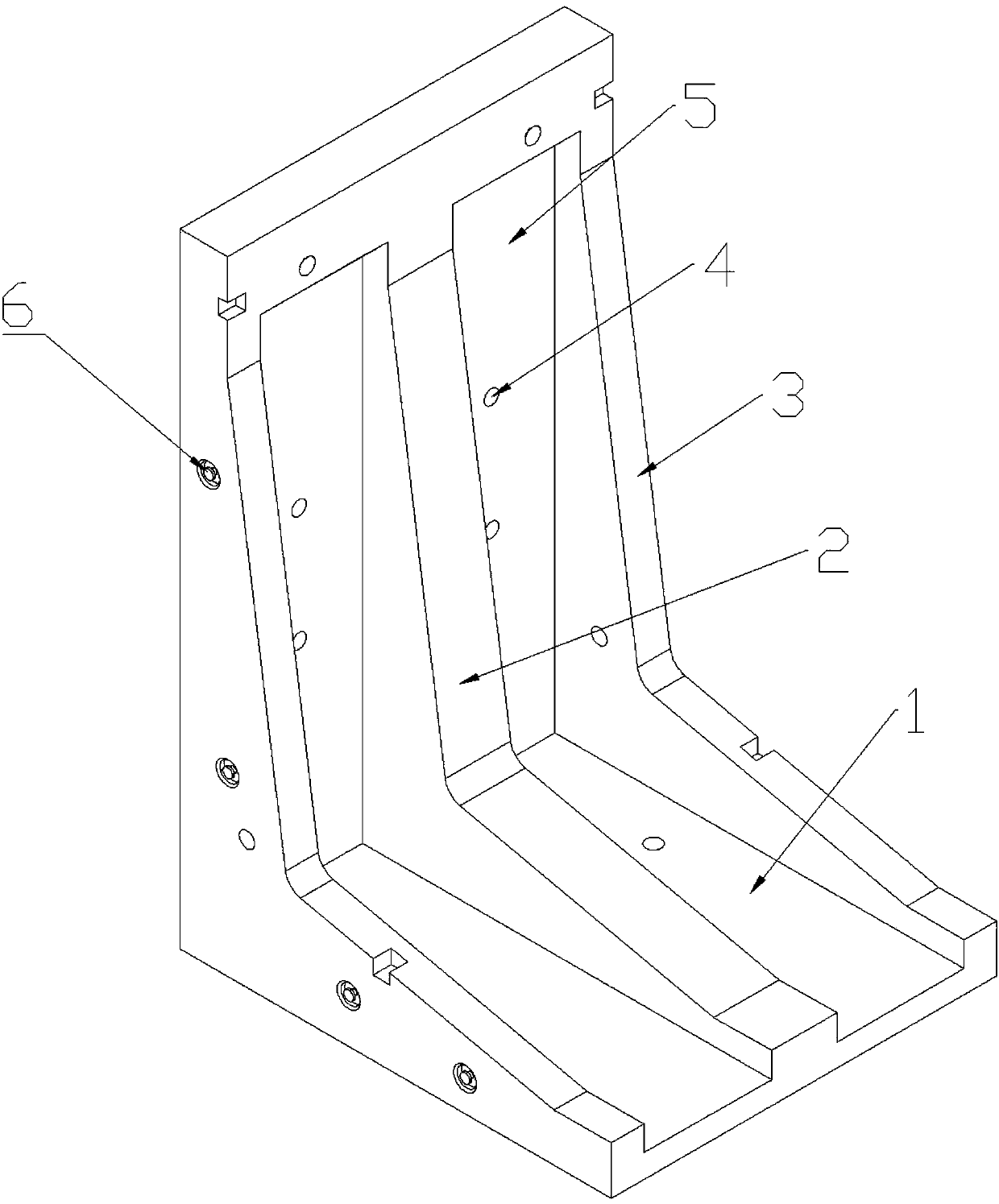

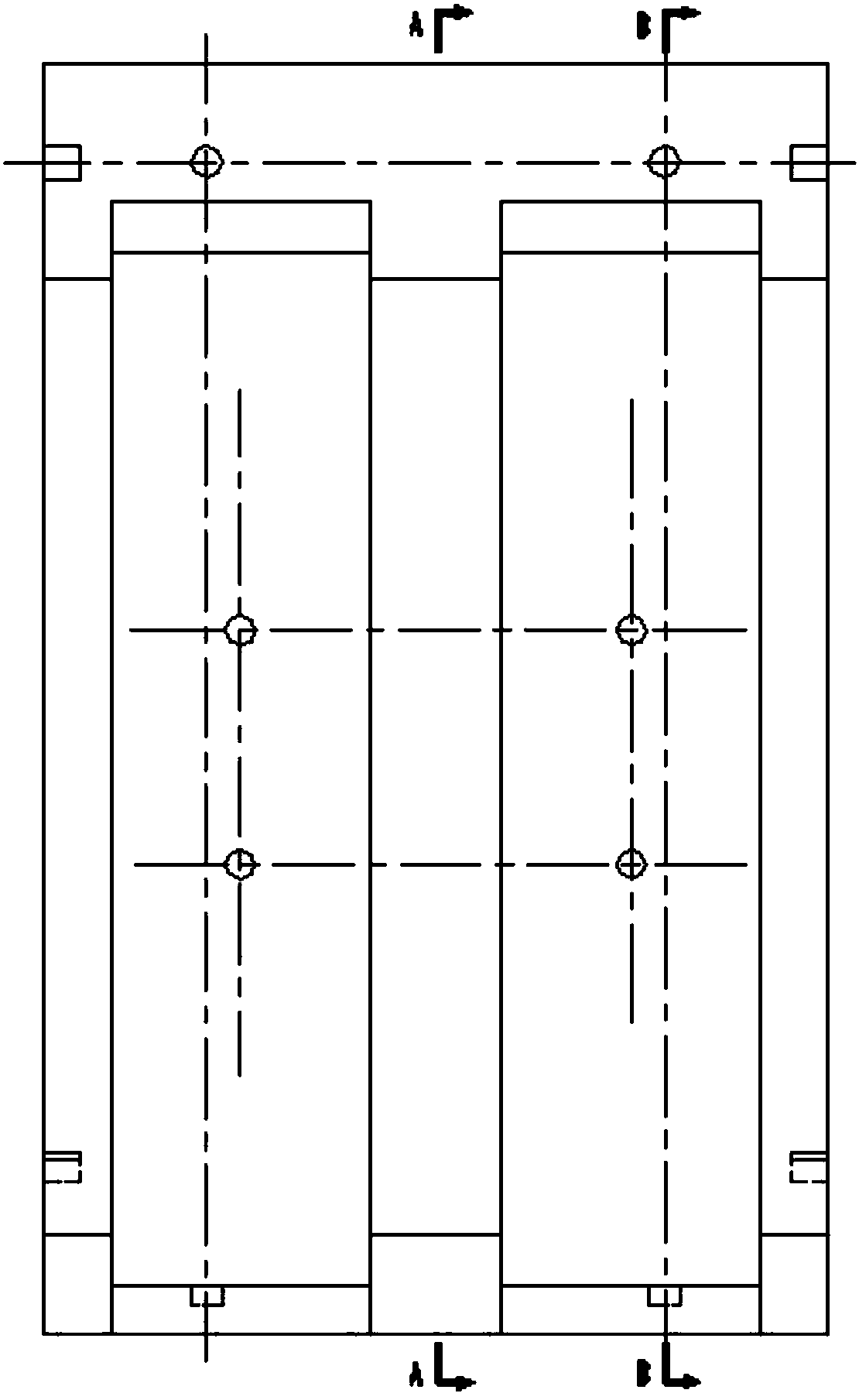

[0025] The vertical plate 5, the bottom plate 1, the main rib plate 2 and the side rib plate 3 are an integrally formed structure in which the steel skeleton is poured with concrete in a mold. Modular prefabrication is implemented, which is small in size, convenient in transportation, and easy to assemble. Compared with traditional Formwork is set up on the construction site to set up steel bars and then pour the wall. The present invention is more convenient to use. In actual construction, multiple L-shaped concrete retaining walls pass through the first tenon 7 of one retaining wall and the first tenon and groove of the next retaining wall. 8 cooperate with each other and the second mortise 9 of one retaining wall cooperates with the second mortise 10 of the next retaining wall to make multiple concrete retaining walls integrated, thus making the retaining wall more stable as a whole.

[0026] Further, the vertical plate 5, the bottom plate 1, the main rib plate 2 and the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com