Low-light-transmittance offline light-gray single silver coating glass and preparation method thereof

A coated glass, light gray technology, applied in the direction of coating, etc., can solve the problems of poor durability and heat insulation performance, achieve good heat insulation and light and heat performance, reduce visible light transmittance, low visible light transmittance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] Its preparation method comprises the following steps:

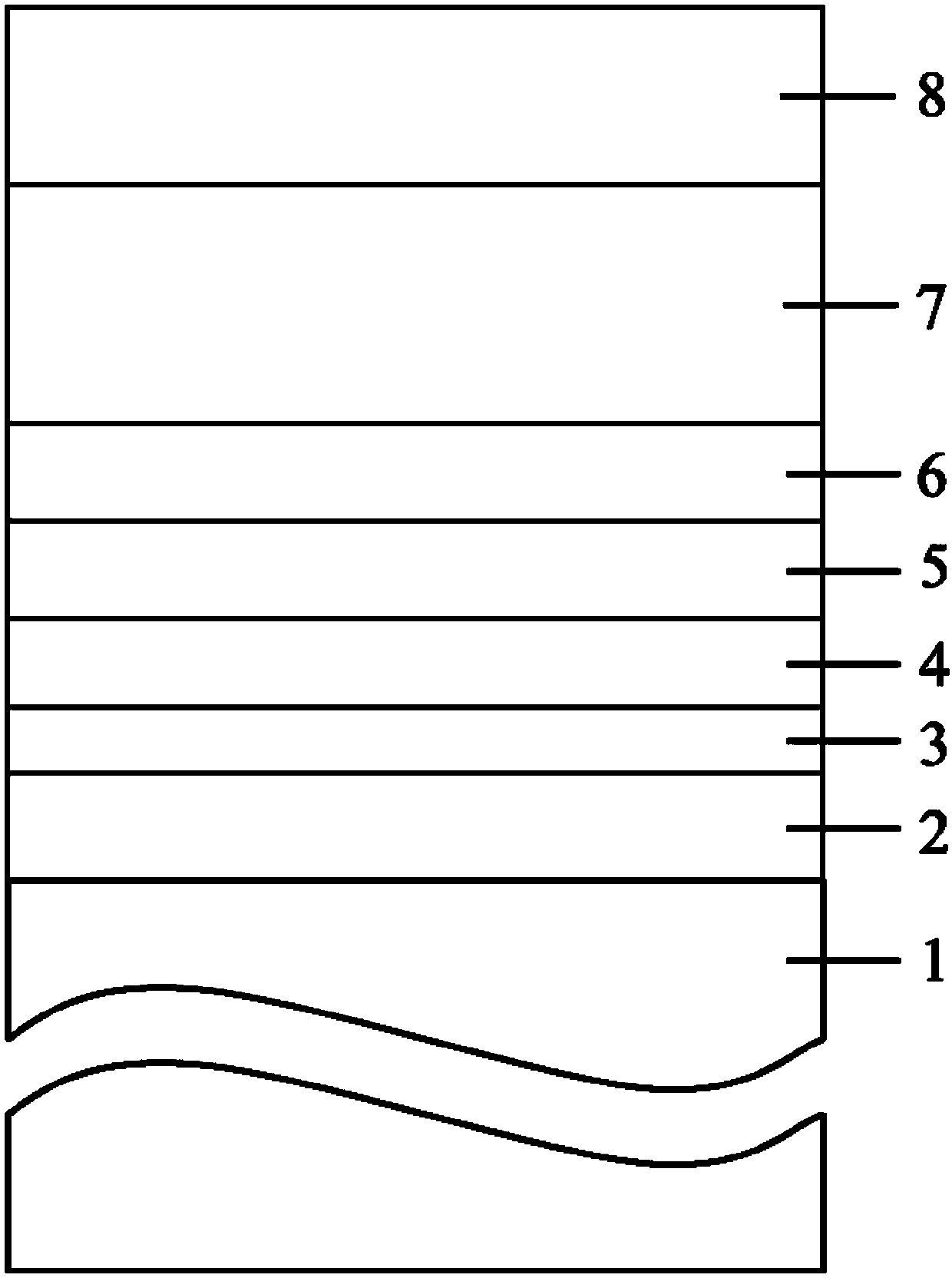

[0048] On the glass substrate 1, a ferromanganese nitride layer 2, a silicon alloy thin film layer 3, a first dielectric layer 4, a first barrier layer 5, an Ag layer 6, and a second barrier layer are sequentially sputtered on a glass substrate 1 by a high-vacuum magnetron sputtering device. 7 and the second dielectric layer 8.

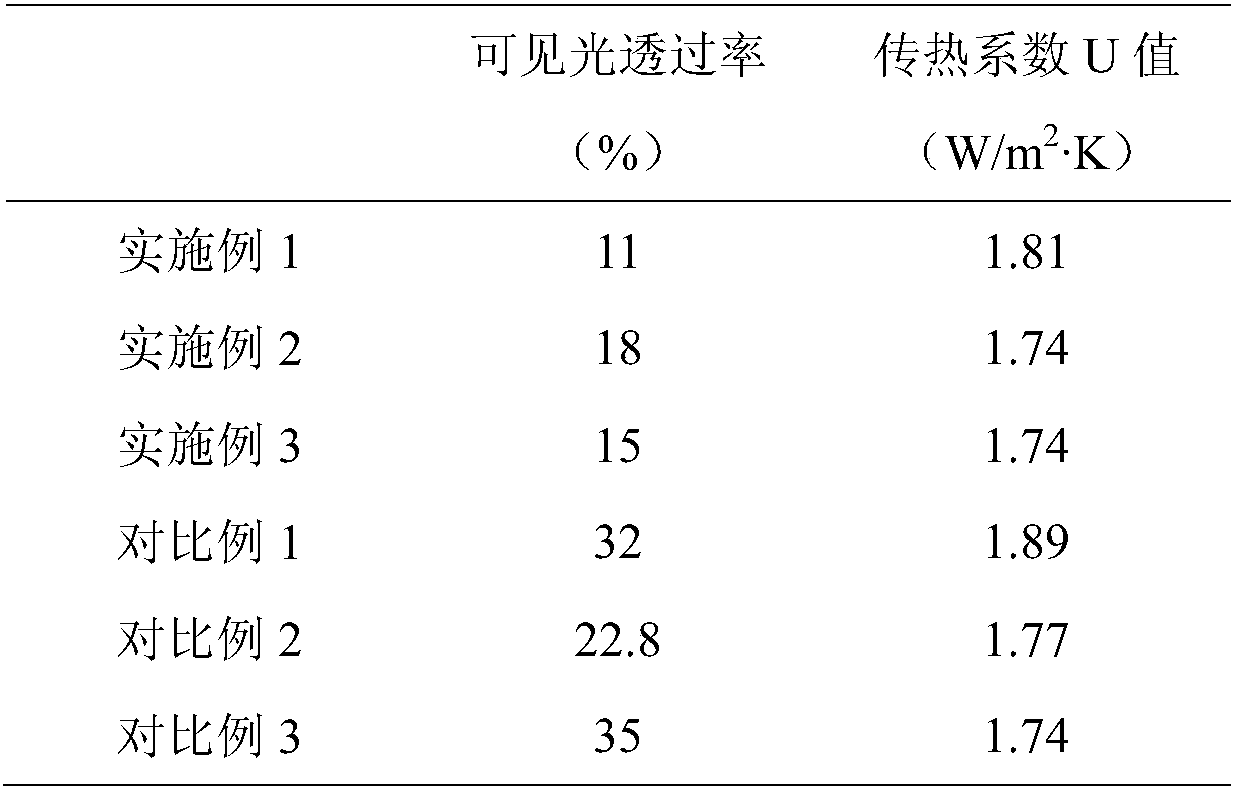

Embodiment 1

[0051] This embodiment provides an off-line light gray single-silver coated glass, which includes a glass substrate 1 and a ferromanganese nitride layer 2, a silicon-manganese-titanium alloy film layer 3, and a first dielectric layer sequentially arranged on the glass substrate. Silicon nitride layer 4 , first barrier layer nickel-chromium layer 5 , Ag layer 6 , second barrier layer nickel-chromium layer 7 and second dielectric layer silicon nitride layer 8 .

[0052] Its preparation method comprises the following steps:

[0053] (1) cutting the glass substrate with a thickness of 6 mm with a cutting machine, and then cleaning with a cleaning machine;

[0054] (2) Set the basic vacuum degree of the high vacuum magnetron sputtering coating device to 10 -3 hPa, line speed is set to 3m / min;

[0055] (3) glass substrate 1 is sent into coating chamber, the power that the first high-vacuum magnetron sputtering coating device is set is 22kW, sputtering forms thickness on glass subs...

Embodiment 2

[0063] This embodiment provides an off-line light gray single-silver coated glass, which includes a glass substrate 1 and a ferromanganese nitride layer 2, an iron-silicon-titanium alloy thin film layer 3, and a first dielectric layer sequentially arranged on the glass substrate. Silicon nitride layer 4 , first barrier layer nickel-chromium layer 5 , Ag layer 6 , second barrier layer nickel-chromium layer 7 and second dielectric layer silicon nitride layer 8 .

[0064] Its preparation method comprises the following steps:

[0065] (1) cutting the glass substrate with a thickness of 6 mm with a cutting machine, and then cleaning with a cleaning machine;

[0066] (2) Set the basic vacuum degree of the high vacuum magnetron sputtering coating device to 10 -3 hPa, line speed is set to 3m / min;

[0067] (3) glass substrate 1 is sent into coating chamber, the power that the first high-vacuum magnetron sputtering coating device is set is 20kW, sputtering forms thickness on glass sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com