Ozone catalytic oxidation-biological aerated filter tower co-processing device and method for leachate mbr effluent

A technology of ozone catalytic oxidation and aerated organisms, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. Problems such as component fouling and clogging can be achieved to achieve comprehensive utilization, improve aeration efficiency, and achieve high-efficiency utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

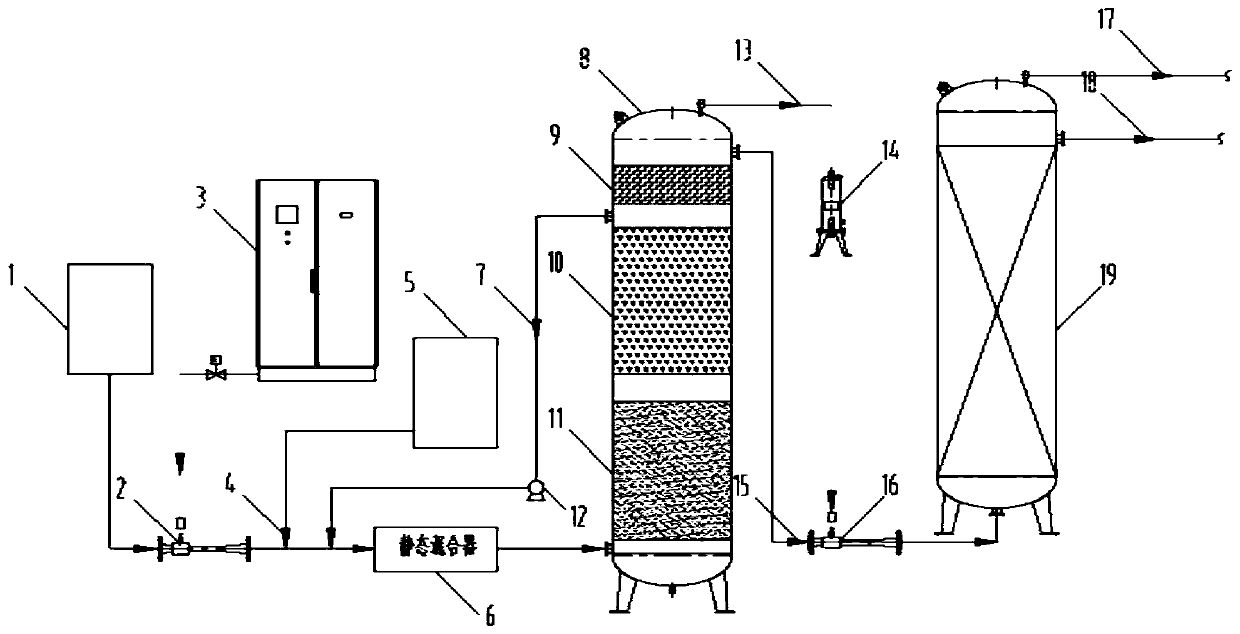

[0060] Taking the MBR effluent from a landfill as the treatment object, the water quality indicators are CODcr 620mg / L, pH 7.8, conductivity 15.1ms / cm, and water volume 2m 3 / h. First, the built-in MBR effluent of the landfill digestion tank is sent to the leachate MBR effluent storage tank 1. cr The mass ratio is controlled at 14:1; the mass ratio of hydrogen peroxide dosage to ozone oxygen dosage is controlled at 1:100. The circulation ratio of the control circulation pump is 40%. The height ratio of the defoaming zone in the ozone catalytic oxidation tower to the ozone catalytic oxidation tower is 1:10, and the defoaming zone is filled with wire mesh defoaming packing; the height ratio of the first catalytic zone to the catalytic oxidation tower is 1:4, and the catalyst loaded is granular Noble Palladium Nickel Metal and MnO Supported on Polysilicic Clinoptilolite 2 The active component has a particle size of 4mm; the height ratio of the second-stage catalytic zone to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com