Preparation and application of printing and dyeing sewage treatment agent

A sewage treatment agent, printing and dyeing sewage technology, applied in water/sewage treatment, adsorption water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of limited industrial application, high price, poor dispersion, etc., and achieve excellent adsorption capacity , Reduce processing costs, good flocculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

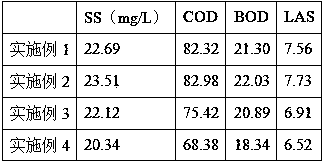

Examples

Embodiment 1

[0018] A kind of preparation of printing and dyeing sewage treatment agent, comprises the preparation of modified coconut shell activated carbon powder, the preparation of modified bentonite and the preparation of sewage treatment agent, and its preparation specifically comprises the following steps:

[0019] 1) Preparation of modified coconut shell activated carbon powder: crush the coconut shell and pass through a 100-mesh sieve, add the coconut shell powder to the phosphoric acid solution with a mass concentration of 70% according to the material-liquid ratio of 1:2, and soak at 70°C 30h, filter, then calcined and activated at 500°C for 3h, take it out and cool naturally, then wash the sample with deionized water until neutral, dry at 70°C, grind, pass through a 250-mesh sieve, and then according to the ratio of material to liquid: Add 0.7mol / L copper nitrate solution at 1:2, then add 0.3mol / L cerium nitrate solution according to the material-to-liquid ratio of 1:0.8, soak f...

Embodiment 2

[0025] A kind of preparation of printing and dyeing sewage treatment agent, comprises the preparation of modified coconut shell activated carbon powder, the preparation of modified bentonite and the preparation of sewage treatment agent, and its preparation specifically comprises the following steps:

[0026] 1) Preparation of modified coconut shell activated carbon powder: crush the coconut shell and pass through a 50-mesh sieve, add the coconut shell powder to the phosphoric acid solution with a mass concentration of 60% according to the material-liquid ratio of 1:4, and soak at 90°C 20h, filter, then calcined and activated at 700°C for 2h, take it out and cool naturally, then wash the sample with deionized water until neutral, dry at 90°C, grind, pass through a 150-mesh sieve, and then according to the ratio of material to liquid: Add 0.4mol / L copper nitrate solution at 1:4, then add 0.1mol / L cerium nitrate solution according to the material-to-liquid ratio of 1:1.3, soak fo...

Embodiment 3

[0032] A kind of preparation of printing and dyeing sewage treatment agent, comprises the preparation of modified coconut shell activated carbon powder, the preparation of modified bentonite and the preparation of sewage treatment agent, and its preparation specifically comprises the following steps:

[0033] 1) Preparation of modified coconut shell activated carbon powder: crush the coconut shell and pass through an 80-mesh sieve, add the coconut shell powder to the phosphoric acid solution with a mass concentration of 65% according to the material-liquid ratio of 1:3, and soak at 80°C 25h, filter, then calcined and activated at 600°C for 2.5h, take it out and cool naturally, then wash the sample with deionized water until neutral, dry at 80°C, grind, pass through a 200-mesh sieve, and then press the ratio of material to liquid Add 0.5mol / L copper nitrate solution to 1:3, then add 0.2mol / L cerium nitrate solution according to the ratio of material to liquid 1:1, soak for 25h, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com