Method for preparing high-silicon CHA type SSZ-13 molecular sieve

A molecular sieve and high-silicon technology, applied in molecular sieves and alkali exchange compounds, chemical instruments and methods, inorganic chemistry, etc., to achieve the effects of high solid phase yield, increased solid phase yield, and shortened crystallization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

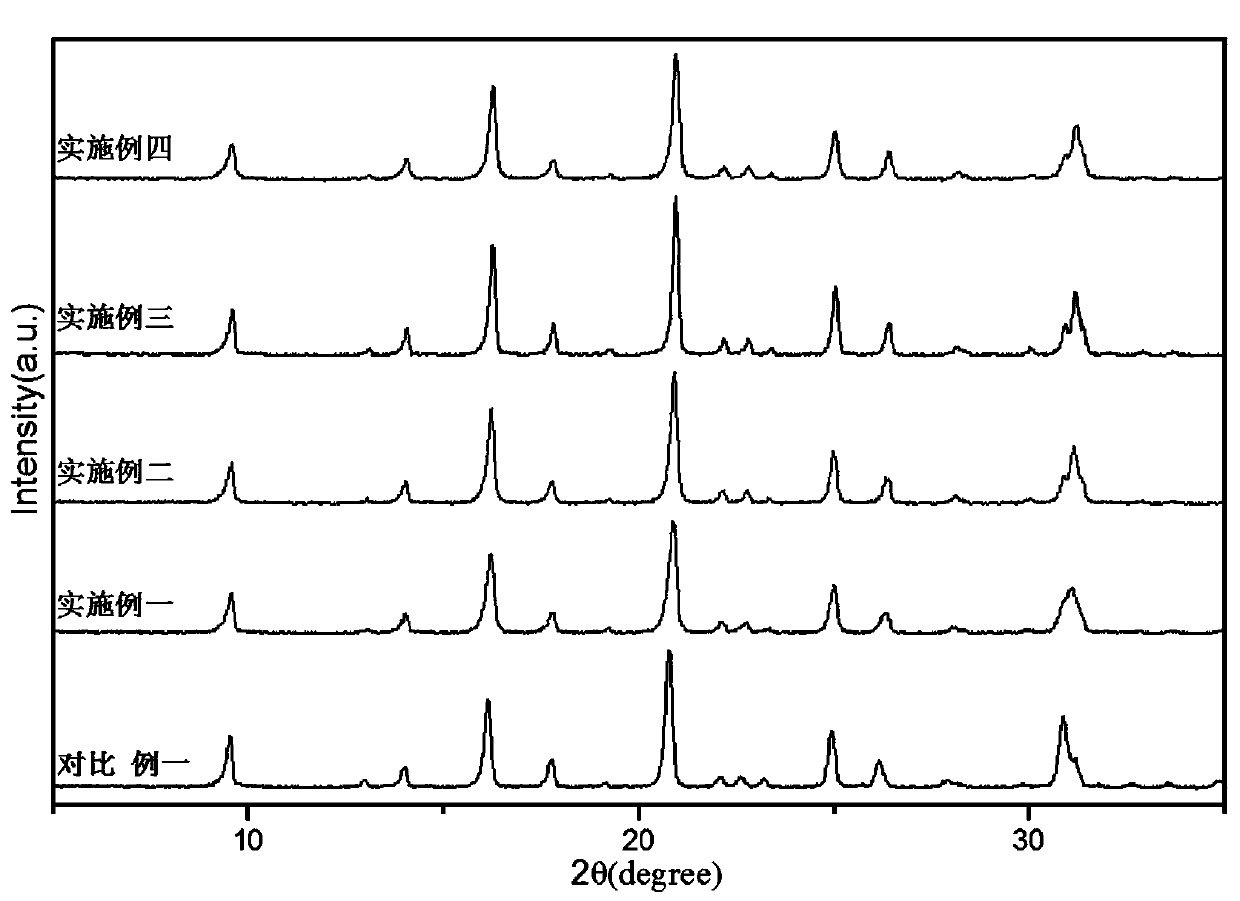

Image

Examples

preparation example Construction

[0030] Preparation of starting material LTL type L zeolite:

[0031] Under the condition of stirring at room temperature, 40 g of deionized water, 1.48 g of sodium hydroxide (NaOH, 96 wt%) and 3.164 g of KOH were stirred in a beaker until dissolved, and then 1.088 g of NaAlO 2 (Al 2 o 3 , 41.3wt%; Na 2 O, 35%), slowly add 8.696g of white carbon black (SiO 2 , 92wt%), stirred vigorously for 2h. The resulting reaction gel was transferred to a stainless steel reaction vessel with a Teflon liner. Static aging at room temperature for 24 hours, constant temperature crystallization at 170°C for 12 hours, quenching to room temperature, washing the product, filtering, and drying to obtain NaK type L zeolite molecular sieve powder, which was used as the starting material of Example 1; NaK type L Zeolite and 1mol / L NH 4 The Cl aqueous solution was mixed with a solid-to-liquid ratio of 1g: 20mL and added to the conical flask, heated in a water bath at 80°C and stirred for 2 hours, t...

Embodiment 1

[0041] NaK type L zeolite was converted into SSZ-13 molecular sieve as the starting zeolite. Proceed as follows:

[0042] Under stirring conditions at room temperature, 20.925g of N,N,N-trimethyladamantane ammonium hydroxide solution (TMADaOH, 25wt%), 21.431g of deionized water and 0.345g of sodium hydroxide (NaOH, 96wt%), Mix and stir in a beaker until clear, then slowly add 4.575 g of silica (SiO 2 , 92wt%), after stirring vigorously for 2h, add 0.95g of NaK type L zeolite (SiO in L zeolite 2 is 15% of the total mass of the silicon source), after stirring for 1 h, finally add 0.105 g of roasted SSZ-13 seed crystals accounting for 2% of the total mass of the silicon source, stir vigorously at room temperature for 1 h, and transfer the above mixture to a polytetrafluoroethylene Lined stainless steel reactor. Crystallize at 155°C for 72h, take it out, and quench it to room temperature, wash it with deionized water until neutral, dry it at 100°C, and roast it in air at 550°C ...

Embodiment 2

[0044] NH 4 Type L zeolite was used as the starting zeolite to synthesize SSZ-13 molecular sieve. Proceed as follows:

[0045] Under stirring conditions at room temperature, 13.95 g of N,N,N-trimethyladamantane ammonium hydroxide solution (TMADaOH, 25 wt%), 19.237 g of deionized water and 0.345 g of sodium hydroxide (NaOH, 96 wt%) were mixed in Mix and stir in a beaker until clear, then slowly add 5.005g of white carbon black (SiO 2 , 92wt%), after stirring vigorously for 2h, add NH 4 Type L zeolite 0.445g (SiO in L zeolite 2 is 7% of the total mass of the silicon source), stirred for 1 h, and finally added 0.0525 g of roasted SSZ-13 seed crystals accounting for 1% of the total mass of the silicon source, continued to stir at room temperature for 1 h, and transferred the above mixture to a polytetrafluoroethylene-lined stainless steel reactor. Crystallize at 155°C for 60h, take it out, and then quench it to room temperature, wash it with deionized water until neutral, dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com