Lateral support structure of marine equipment

A support structure, equipment side technology, applied in ship construction, ship parts, ships, etc., can solve problems such as bulkhead damage, reduce equipment deformation, protect from damage, and improve the ability to resist deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

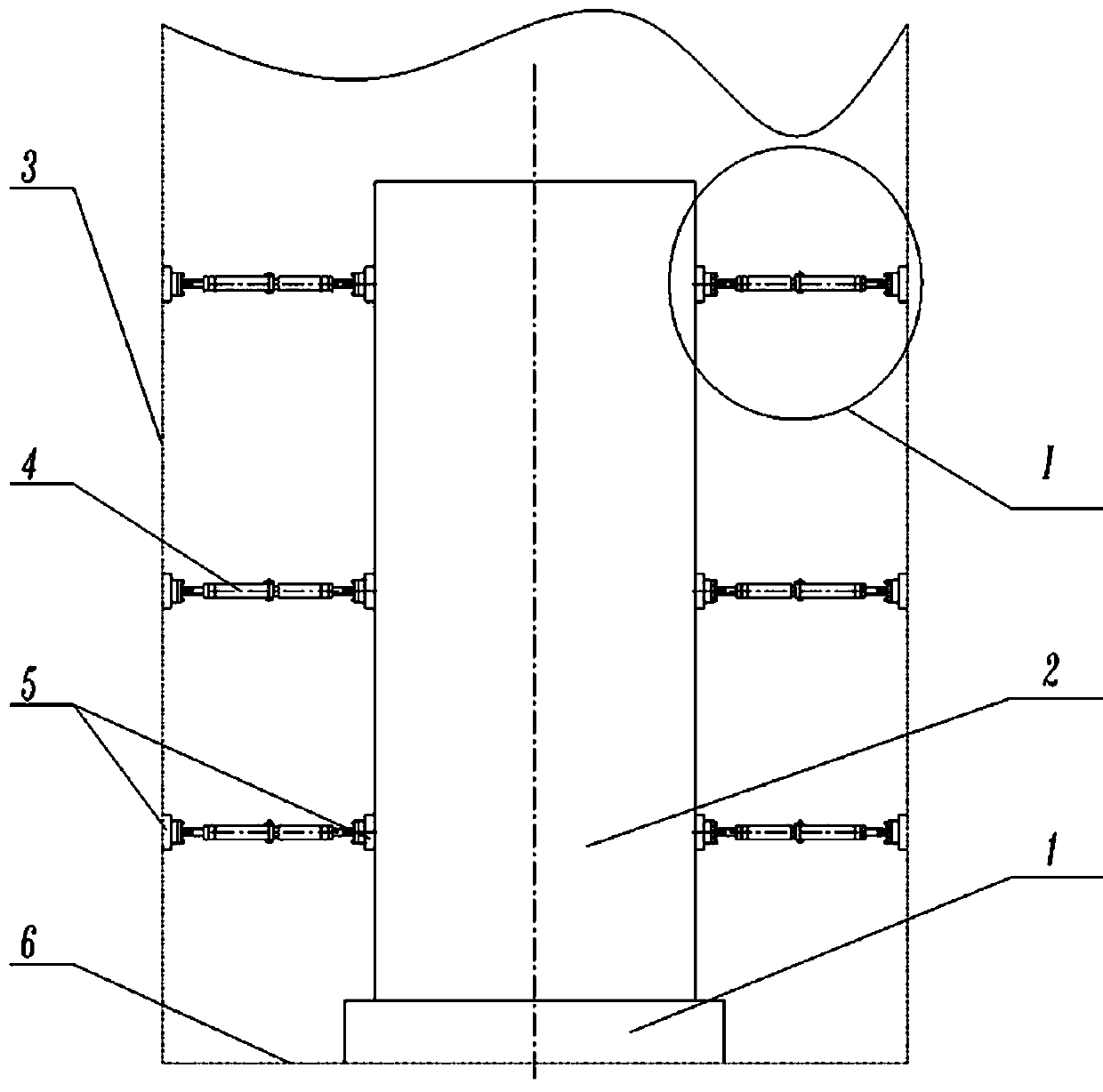

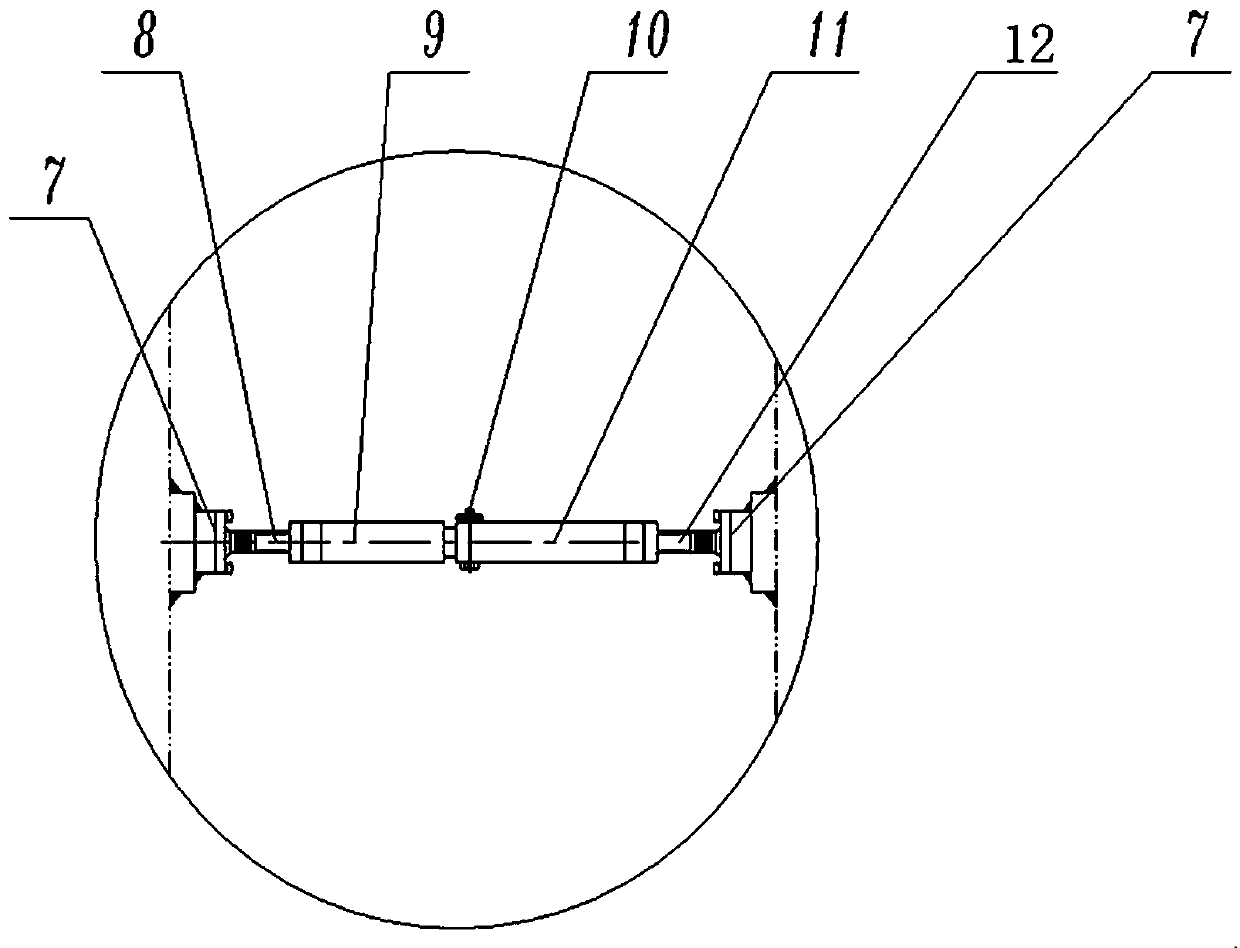

[0017] see figure 1 with figure 2 , the marine equipment lateral support structure provided by the present invention includes: installation seats arranged on the side of the equipment and on the corresponding bulkhead, the installation seats are connected by a support rod 4 with adjustable length, and the two ends of the support rod 4 are spherical joint structures , a shear pin is set in the middle of the support rod 4. According to the actual situation, a multi-layer support rod 4 can be arranged laterally between the equipment and the bulkhead. The ability of the equipment to resist deformation is improved; when the swing load is too large so that the axial force on the support rod 4 reaches a certain value, the shear pin 10 is sheared, the support rod 4 loses its auxiliary supporting function, and the part of the protective bulk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com