Waste material collection device for 3D printer

A 3D printer and waste collection technology, applied in manufacturing auxiliary devices, 3D object support structures, processing and recycling, etc., can solve the problems of reduced work efficiency, low degree of automation, and difficult cleaning, to improve work efficiency, reduce operation effort, The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

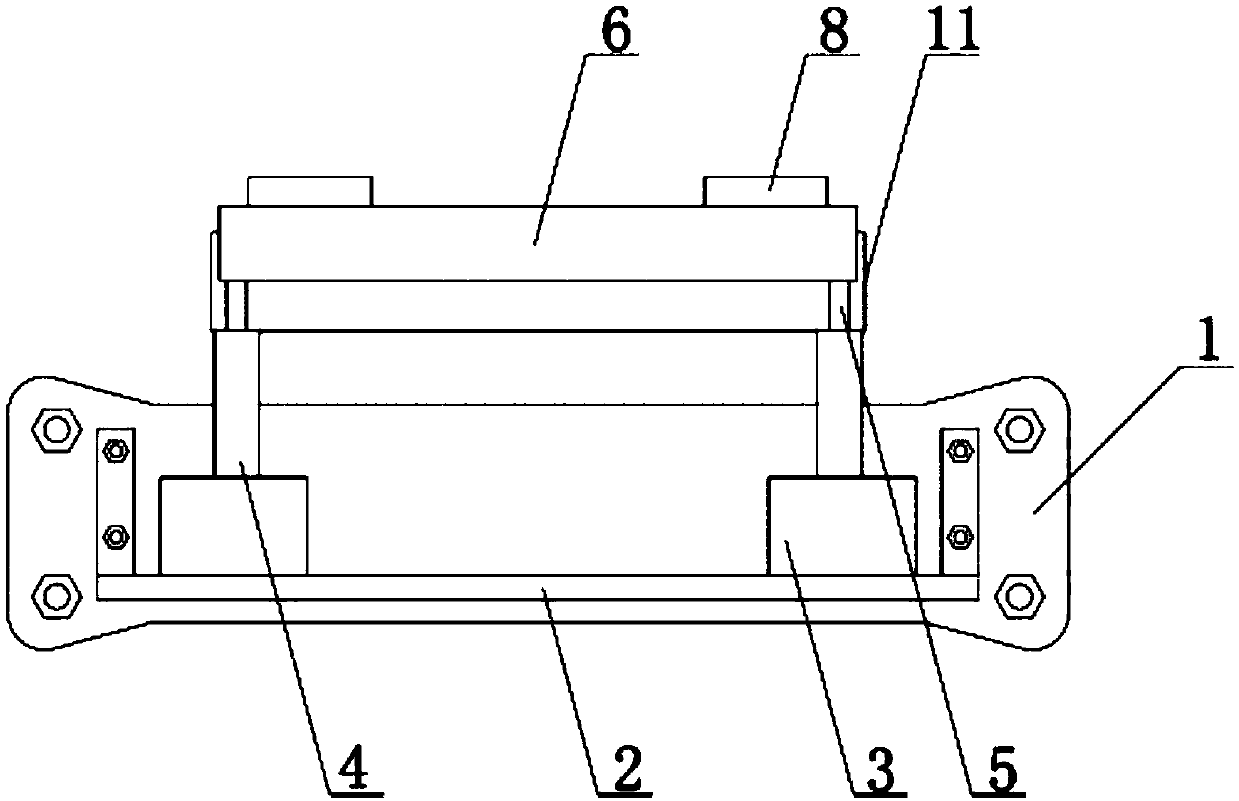

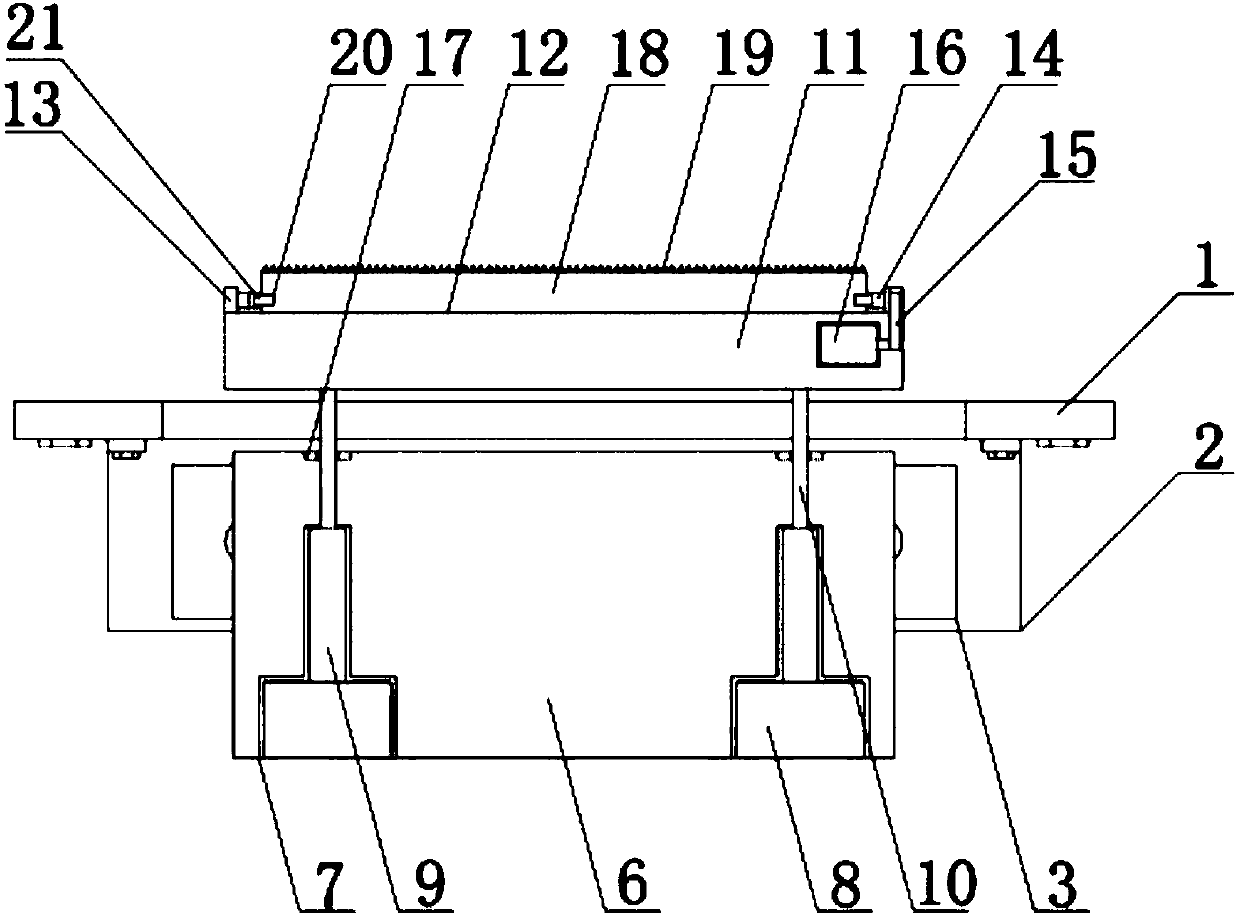

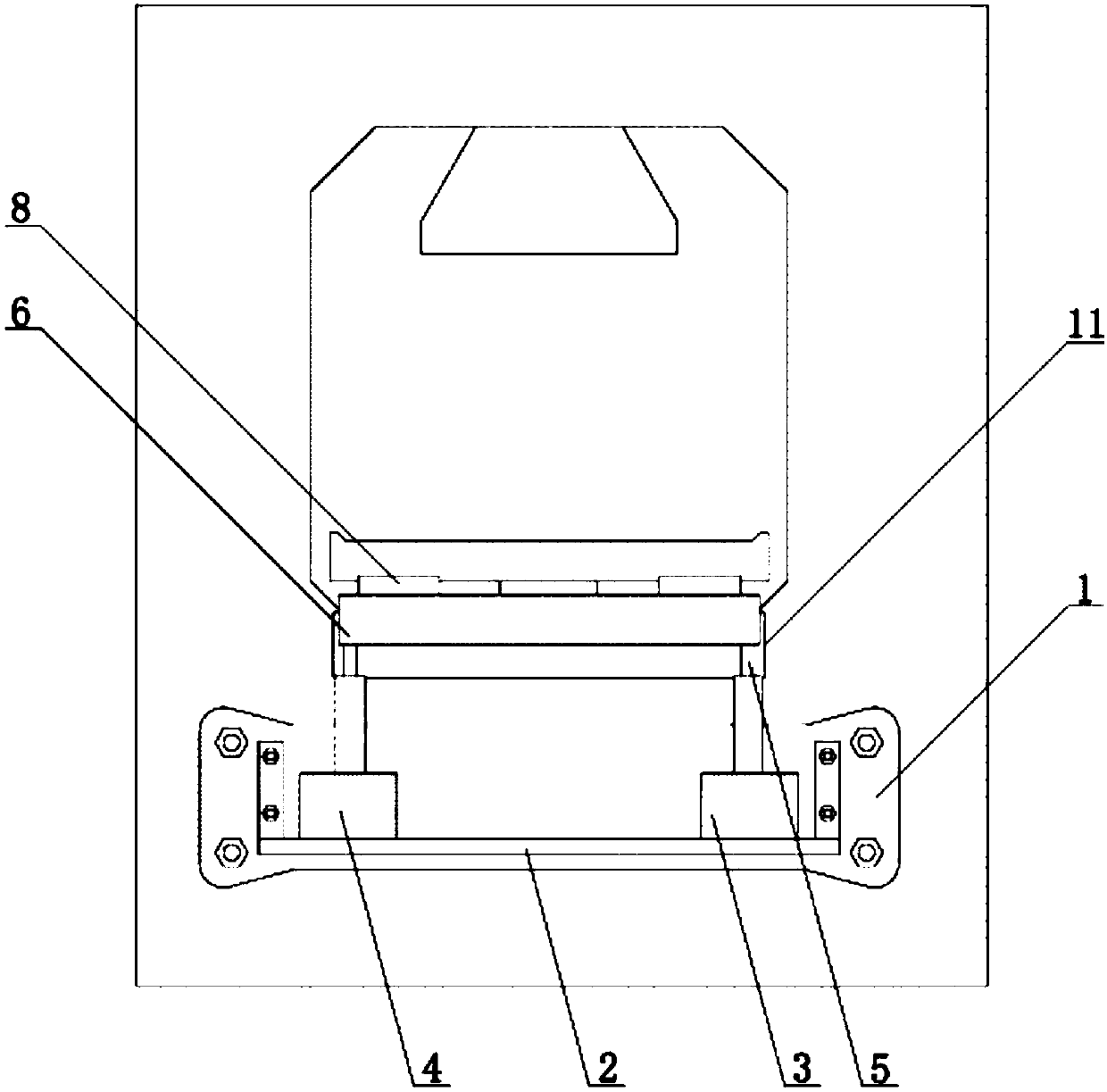

[0018] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] refer to Figure 1-3 The 3D printer waste collection device described in this specific embodiment includes a base 1 installed at the lower part of the 3D printer, a support plate A2, a plunger pump A3, a hydraulic cylinder A4, a hydraulic rod A5, a support plate B6, and a plunger pump B8 , hydraulic cylinder barrel B9, hydraulic rod B10, collection box 11, support A13, roller 14, belt 15 and motor 16, support plate A2 is installed on the base 1, vertical plunger pumps are respectively arranged at the two ends of the support plate A2 top A3, the upper part of the plunger pump A3 is provided with a hydraulic cylinder A4, the upper part of the hydraulic cylinder A4 is provided with a hydraulic rod A5, and the upper part of the adjacent hydraulic rod A5 is fixed with a support plate B6, and the upper part of the support plate B6 is opposite to the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com