Small-load speed-shifting heavy-duty car manual shift control force-changing device

A heavy-duty vehicle, small-load technology, applied in the direction of components with teeth, belts/chains/gears, mechanical equipment, etc., can solve the problems of complex use environment, frequent shifting, affecting the performance and service life of the control system, etc. No change in function, reduced friction loss, and longer service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

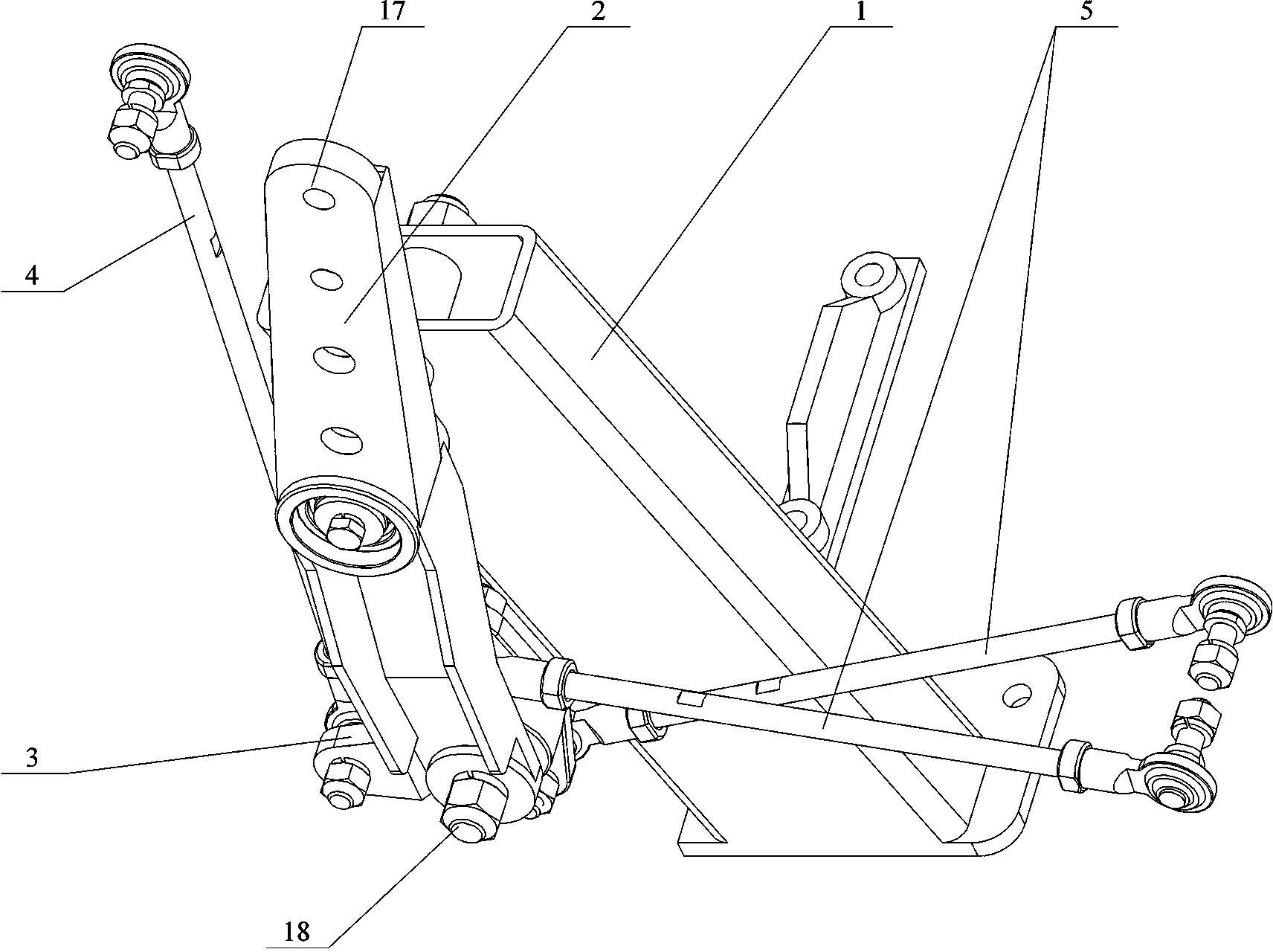

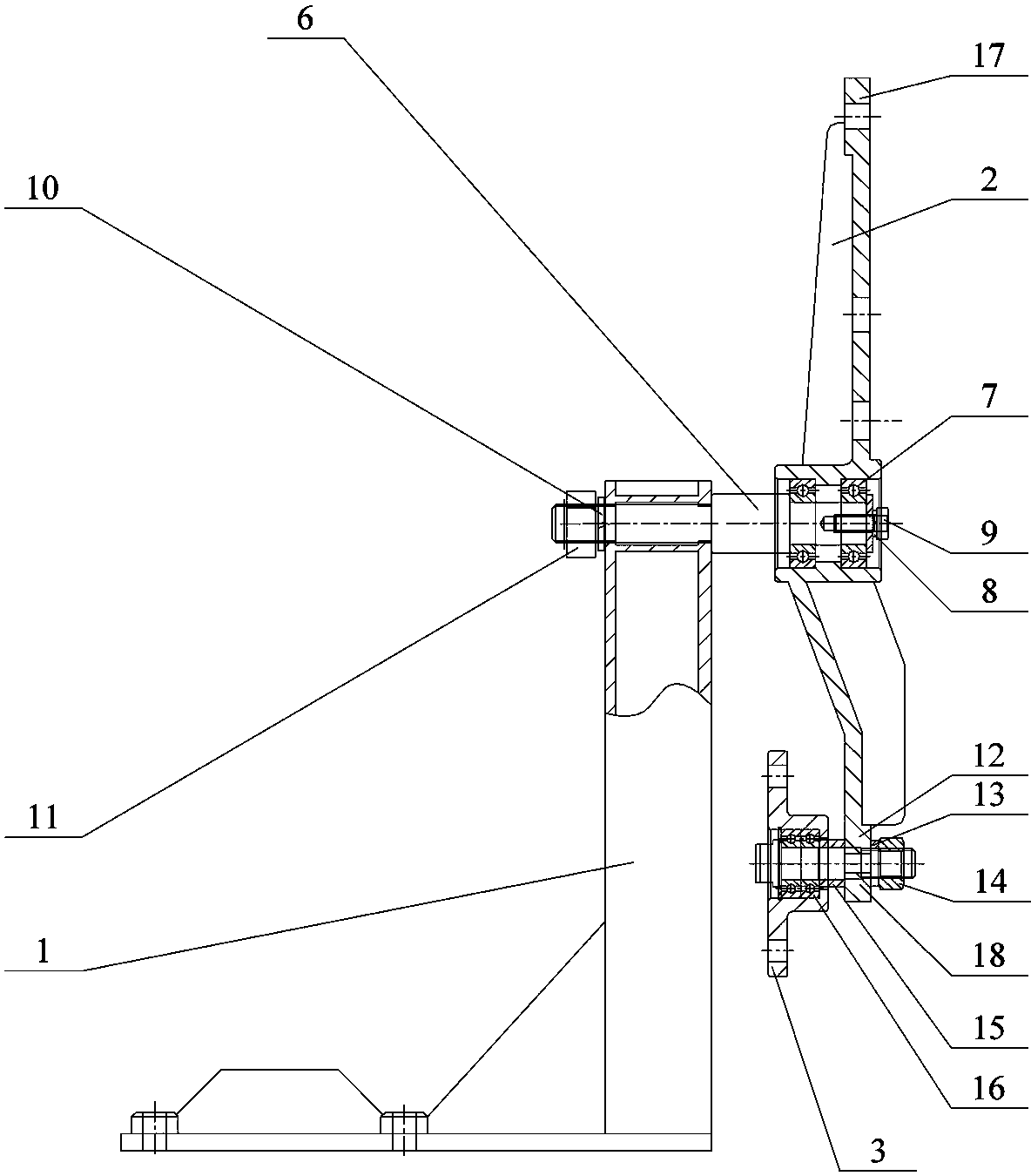

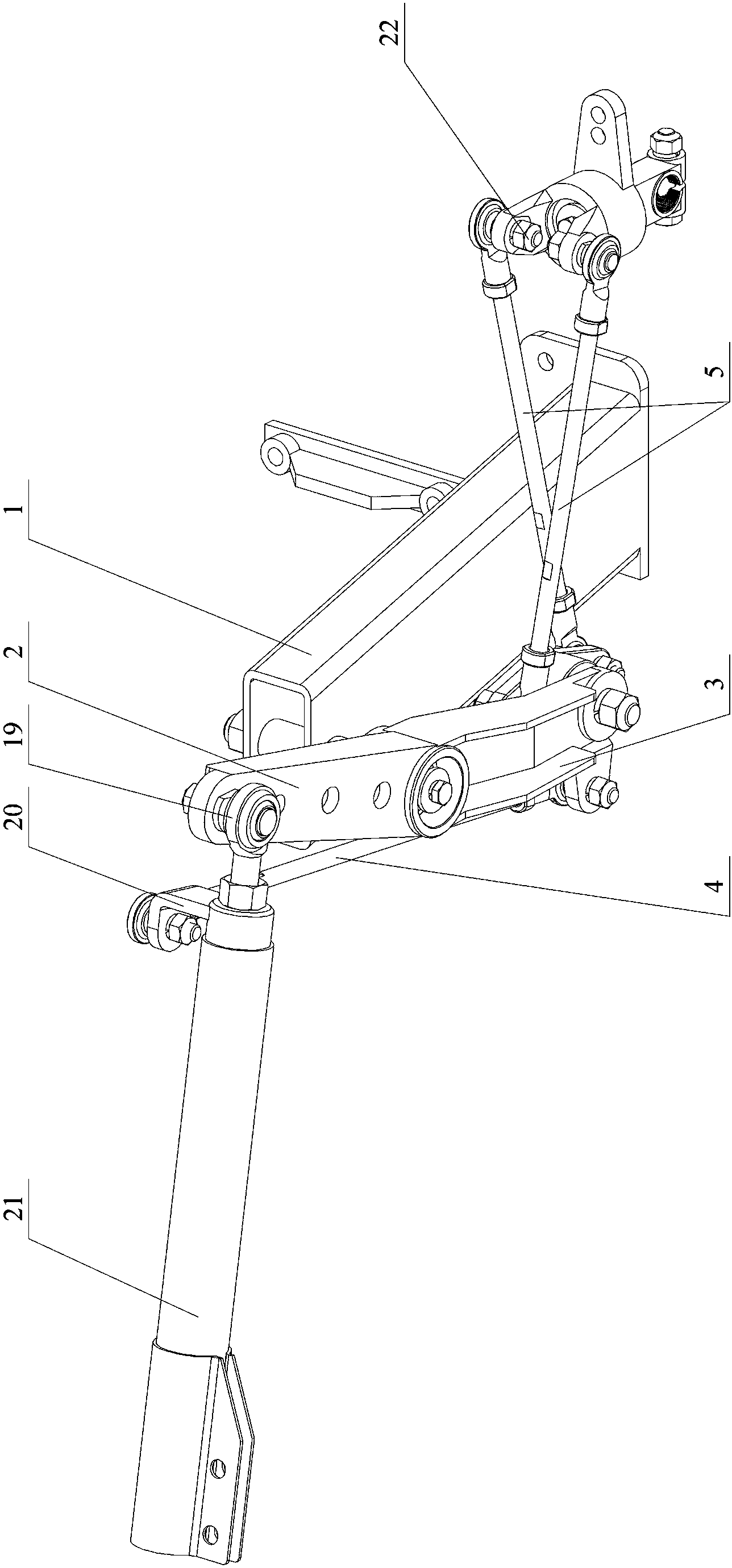

[0014] According to attached figure 1 , 2 And 3, the heavy-duty automobile manual transmission shifting operation power converter with small load shifting of the present invention, the main swing arm (2) connected with the hard rod connecting pipe (21) is installed on the middle power converter bracket (1), the main swing arm (2) The output end (18) is provided with a T-shaped secondary swing arm (3), one end of the secondary swing arm (3) is connected to the hard rod connecting pipe extension arm (20) by the connecting rod A (4), and the other end is connected by the connecting rod A (4). The two connecting rods B (5) are connected to the conversion mechanism (22), and the auxiliary swing arm (3) outputs force to drive the double rods to realize asynchronous and synchronous reciprocating motion. The main swing arm (2) is fixed on the intermediate power converter bracket (1) by two 6004 bearings (7) and the main swing arm shaft (6), and one end is fastened by a D18 spring was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com