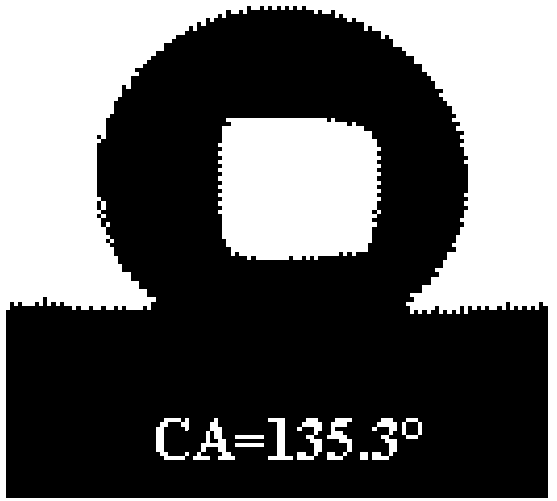

Novel method for improving hydrophobicity of wood

A hydrophobic, wood technology, applied in wood treatment, wood impregnation, wood impregnation, etc., can solve the problems of complex process, high equipment requirements, difficult deep processing, etc., to achieve non-toxic production process, low equipment requirements, thermal stability and The effect of improved dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

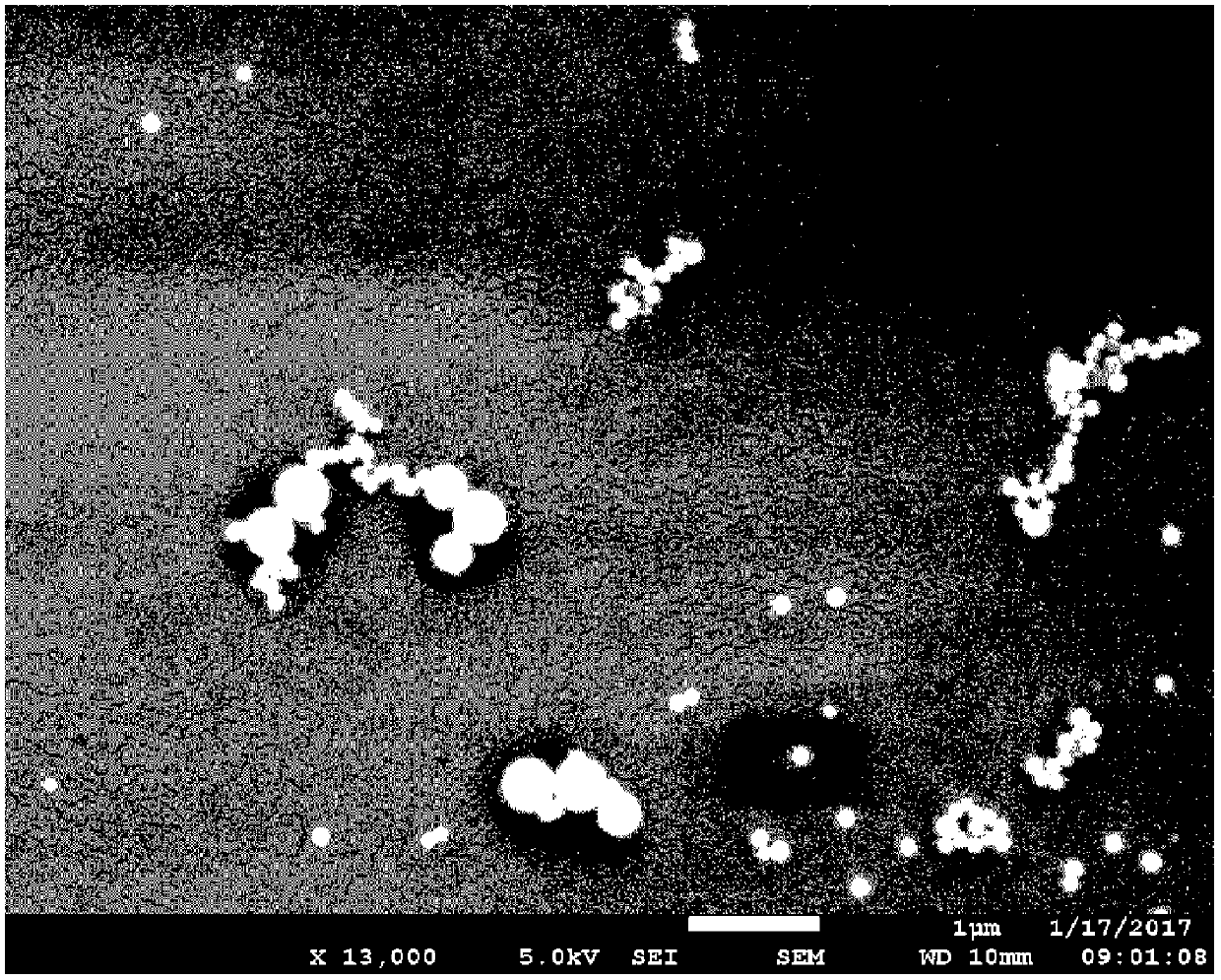

[0021] 1. Mix 3mL of ammonia water and 50mL of ethanol, stir magnetically at 50°C for 30min, add 3mL of tetraethoxysilane dropwise into the above solution, and stir at room temperature for 2h after the dropwise addition to obtain a transparent silica sol;

[0022] 2. Mix vinyltriethoxysilane with the above-prepared silica sol in a weight ratio of 1:1, and magnetically stir for 2 hours at a temperature of 50°C to prepare a composite wood modifier, which is set aside;

[0023] 3. Put the wood in the reaction tank, seal the reaction tank and then evacuate to -0.06MPa, and keep the negative pressure for 20min;

[0024] Four, inject the composite wood modifier obtained in the step (two) into the reaction tank under vacuum, make the wood fully impregnated in the composite modifier, apply ultrasonic treatment to the reaction tank while maintaining the vacuum state, ultrasonic power For 1kW, the wood is subjected to vacuum-ultrasonic impregnation treatment for 2h;

[0025] 5. Release...

Embodiment 2

[0027] 1. Mix 3mL of ammonia water and 50mL of ethanol, stir magnetically at 50°C for 30min, add 3mL of tetraethoxysilane dropwise into the above solution, and stir at room temperature for 2h after the dropwise addition to obtain a transparent silica sol;

[0028] 2. Mix vinyltriethoxysilane with the above-prepared silica sol in a weight ratio of 1:1, and magnetically stir for 2 hours at a temperature of 50°C to prepare a composite wood modifier, which is set aside;

[0029] 3. Put the wood in the reaction tank, seal the reaction tank and then evacuate it to -0.08MPa, and keep the negative pressure for 20 minutes;

[0030] Four, inject the composite wood modifier obtained in the step (two) into the reaction tank under vacuum, make the wood fully impregnated in the composite modifier, apply ultrasonic treatment to the reaction tank while maintaining the vacuum state, ultrasonic power For 1kW, the wood is subjected to vacuum-ultrasonic impregnation treatment for 2h;

[0031] 5....

Embodiment 3

[0033] 1. Mix 3mL of ammonia water and 50mL of ethanol, stir magnetically at 50°C for 30min, add 3mL of tetraethoxysilane dropwise into the above solution, and stir at room temperature for 2h after the dropwise addition to obtain a transparent silica sol;

[0034] 2. Mix vinyltriethoxysilane with the above-prepared silica sol in a weight ratio of 1:1, and magnetically stir for 2 hours at a temperature of 50°C to prepare a composite wood modifier, which is set aside;

[0035] 3. Put the wood in the reaction tank, seal the reaction tank and then evacuate to -0.09MPa, and keep the negative pressure for 20 minutes;

[0036] Four, inject the composite wood modifier obtained in the step (two) into the reaction tank under vacuum, make the wood fully impregnated in the composite modifier, apply ultrasonic treatment to the reaction tank while maintaining the vacuum state, ultrasonic power 1.5kW, the wood is subjected to vacuum-ultrasonic impregnation treatment for 2 hours;

[0037] 5....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com