Laser punching system for cigarette tipping papers

A technology for cigarette tipping paper and laser drilling, applied in laser welding equipment, welding equipment, transportation and packaging, etc., can solve problems such as unqualified, improve production quality and efficiency, reduce impact, and ensure drilling quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

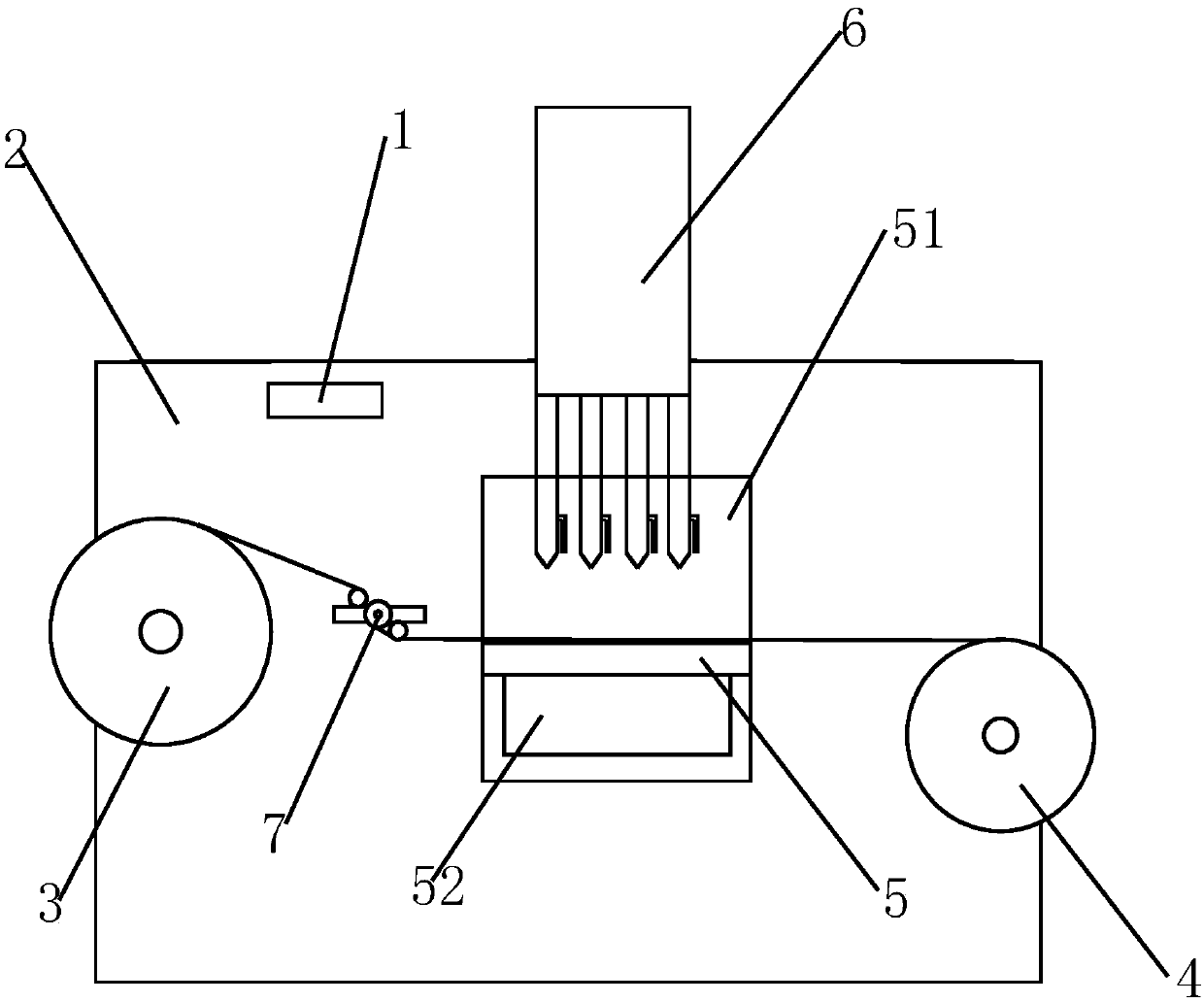

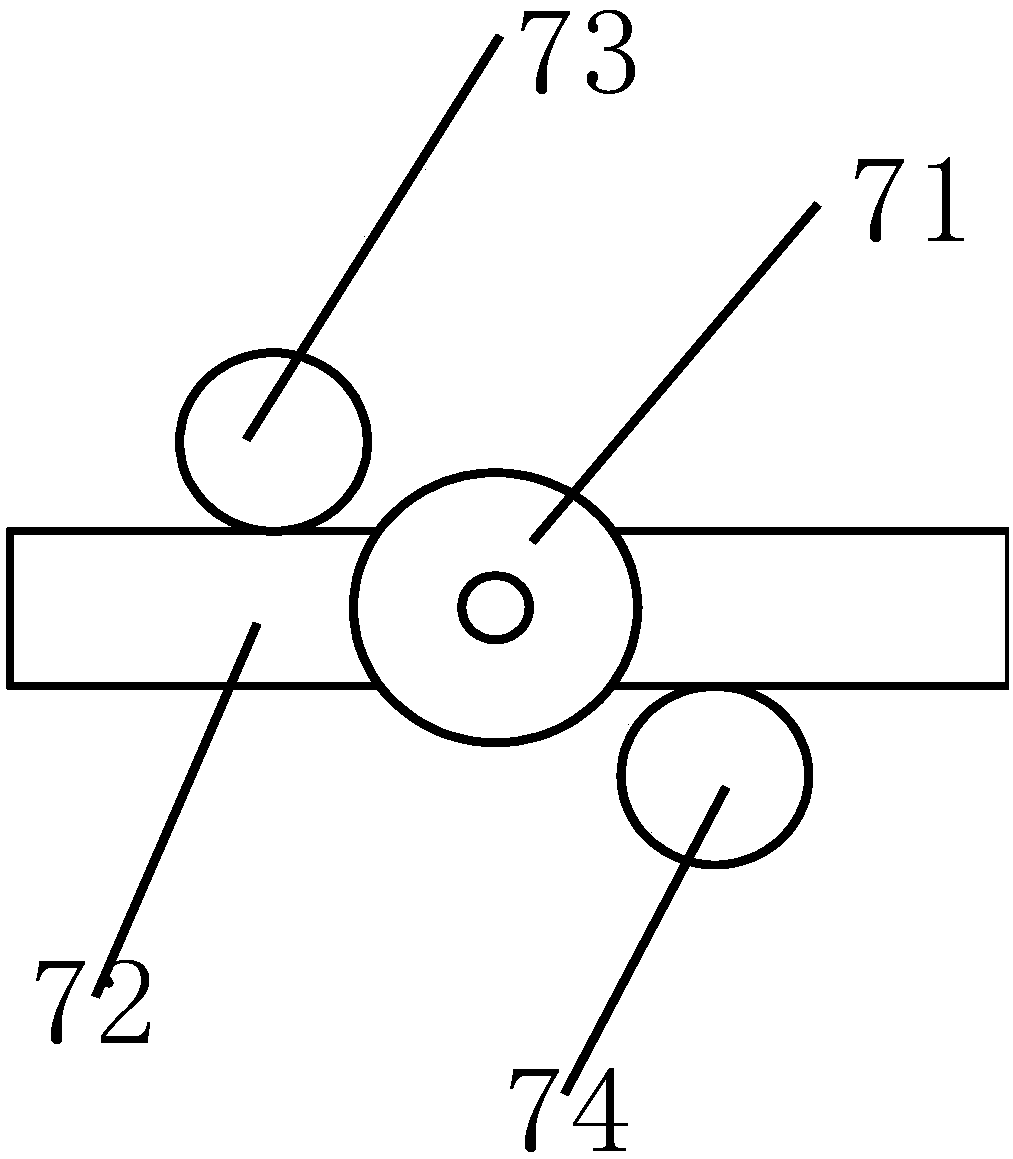

[0024] refer to figure 1 — image 3 , the present invention provides a laser punching system for tipping paper for cigarettes, including a laser punching machine 6 and a winding and unwinding device, and the winding and unwinding device includes a control module 1, a mounting frame 2, and an unwinding device 3 , rewinding device 4, braking mechanism, driving mechanism and perforated support plate 5: the two ends of the mounting frame 2 are symmetrically provided with the unwinding device 3 and the rewinding device 4, and the unwinding device 4 drives Connect the brake mechanism, the winding device 4 is driven and connected by the driving mechanism arranged at the rear of the mounting frame 2, the mounting frame between the unwinding device 3 and the winding device 4 2. A perforated support plate 5 is provided on the platform, and the laser drilling m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com