Automatic film removing and bottle feeding machine

A bottle machine and automatic technology, applied in the field of automatic film removal and bottle loading machine, can solve problems such as high labor intensity, bottle overturning, quality risk, etc., and achieve the effect of reducing labor intensity, reducing transit space, and orderly and safe working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

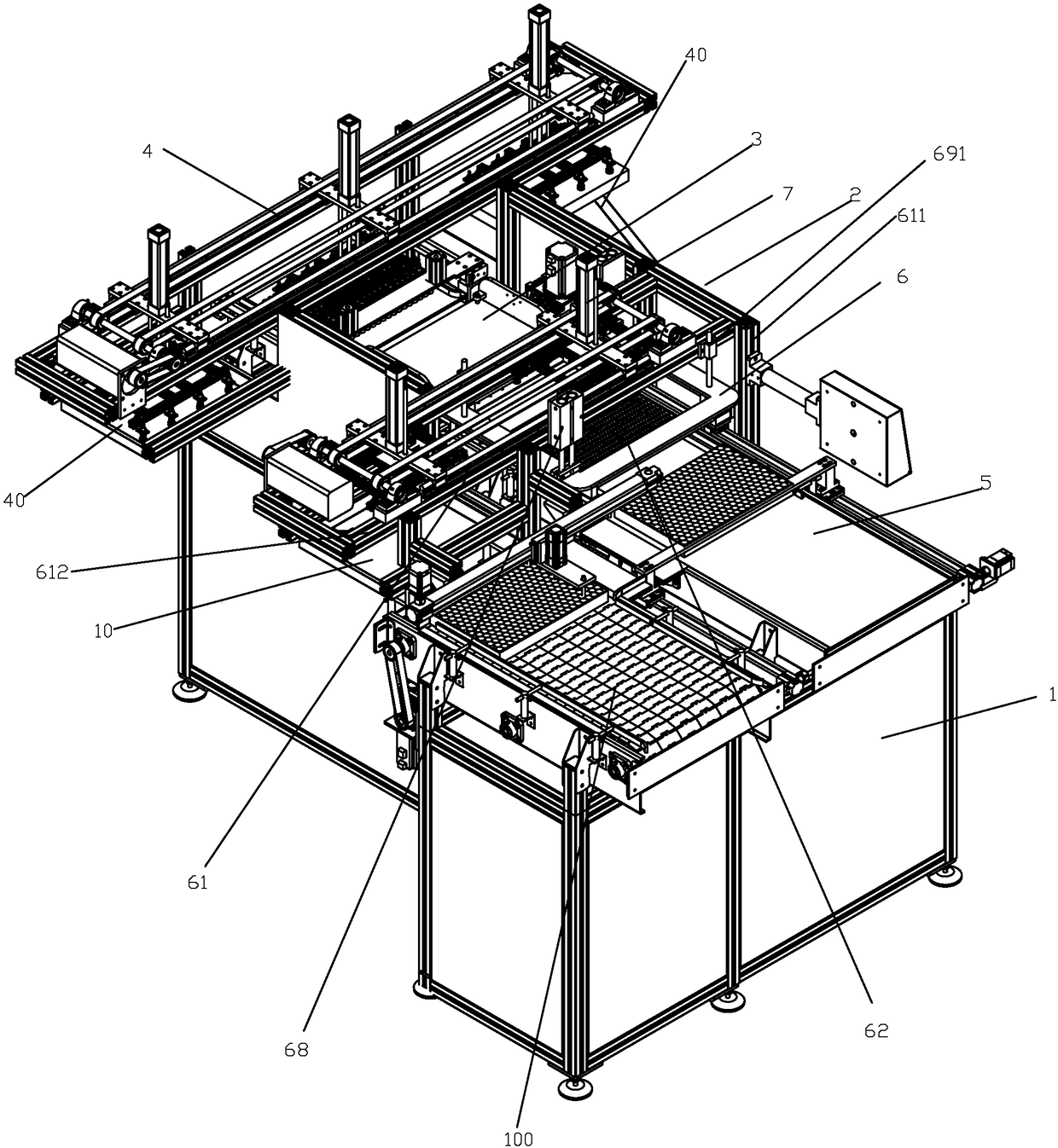

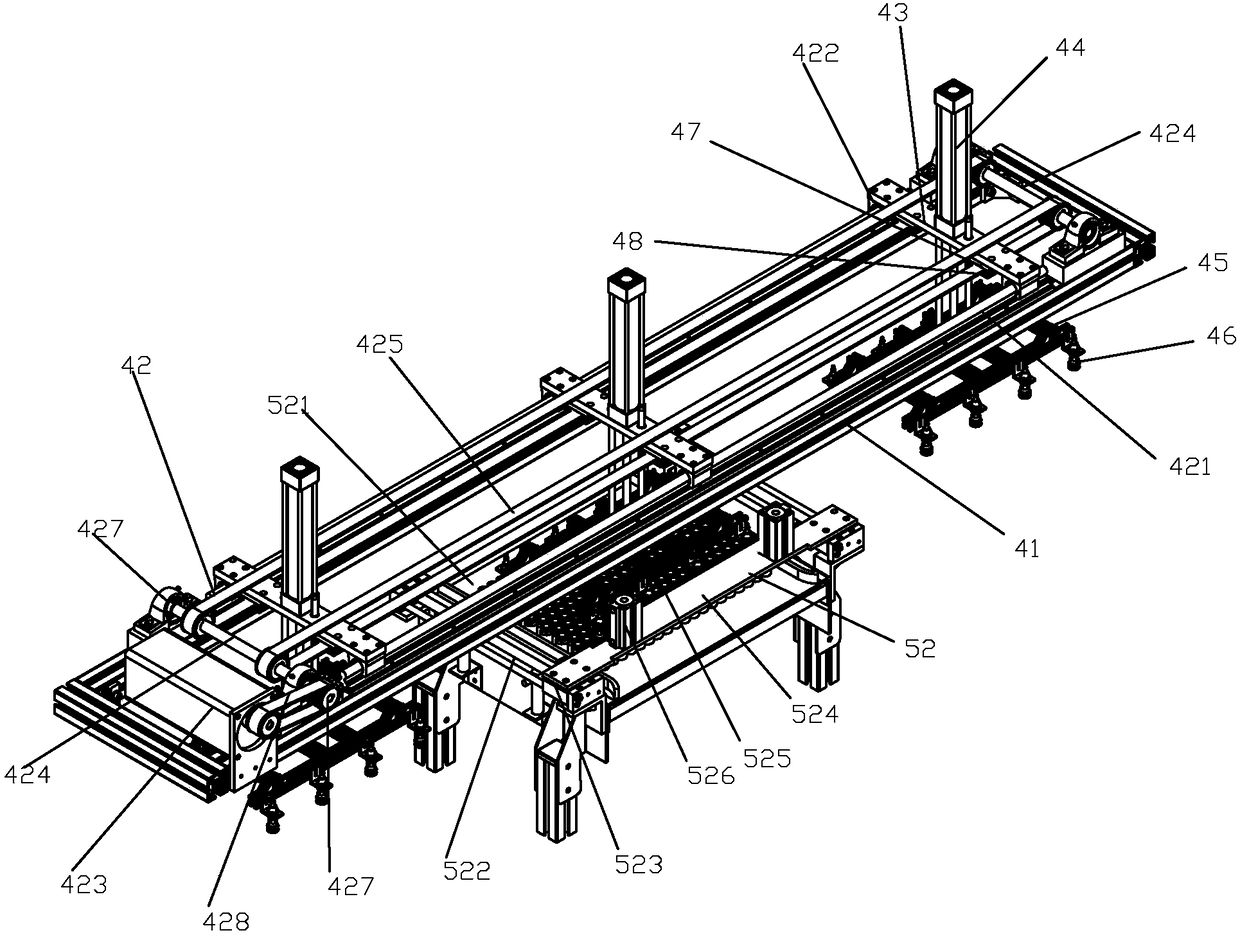

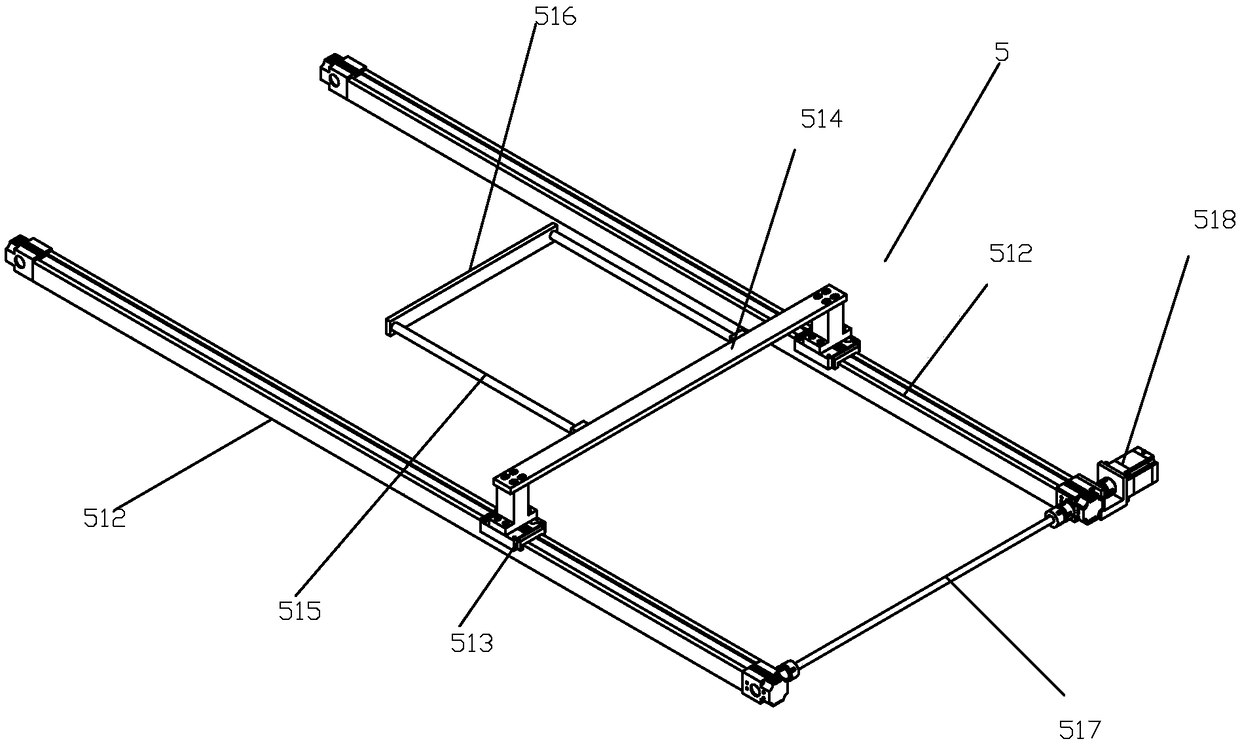

[0022] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] like Figure 1-6 As shown, the technical solution adopted in the present invention is: an automatic film-removing bottle-loading machine, comprising a body 1, the body 1 is sequentially provided with a box film removal device 2, and a box body connected with the box film removal device 2 The overturning device 3 and the box separation device 4 connected with the box overturning device 3, the body 1 is provided with a box transfer that can sequentially transport the boxes from the box film removal device 3 to the box separation device 4 Device 5 ; the film removing device 3 includes a film cutting mechanism 6 and a film removing mechanism 7 . The box body filled with bottles is first transported to the bottom of the box film removal device 2 through the box body transfer device 5, and the box film on the upper layer of the box body is cut off ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com