Involute cutter set and edge parameter calculating method thereof

A technology of involute and knife edge, which is applied in the field of bottle cap involute knife set and its knife edge parameter calculation, can solve the problems of short service life, inability to produce and sell in the same batch, increase production cost, etc., and achieve the goal of reducing production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

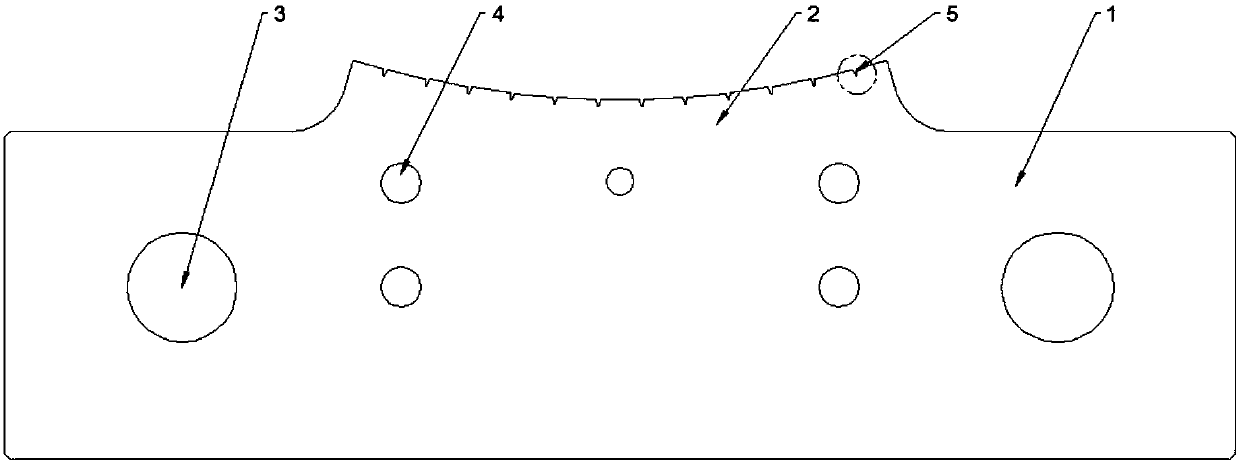

[0116] Such as Figure 6 As shown, when the bottle cap 9 rolls along the blade 2, the edge of the bottle cap 9 is embedded in the blade 2, and the cutting of the involute of the bottle cap 9 is realized through a plurality of knife edges 5 on the blade 2, and the adjacent The knife edge 2 between the two knife edges 5 cuts the bottle cap 9, and the part where the edge of the bottle cap 9 is embedded in the knife edge 5 is not cut.

Embodiment 2

[0118] Such as Figure 7 As shown, the entrance of the knife edge 5 in the prior art is a right-angle structure 10, and the part of the right-angle structure 10 is directly inserted into the bottle cap 9 when the bottle cap 9 rolls along it.

[0119] Such as Figure 8 As shown, after repeated use, the right-angle structure 10 is the most severely worn part of the blade 2, and the casting will become an arc-shaped worn part 11. The worn part 11 not only changes in shape, but is no longer sharp. Cutting of the bottle cap 9 cannot be realized.

Embodiment 3

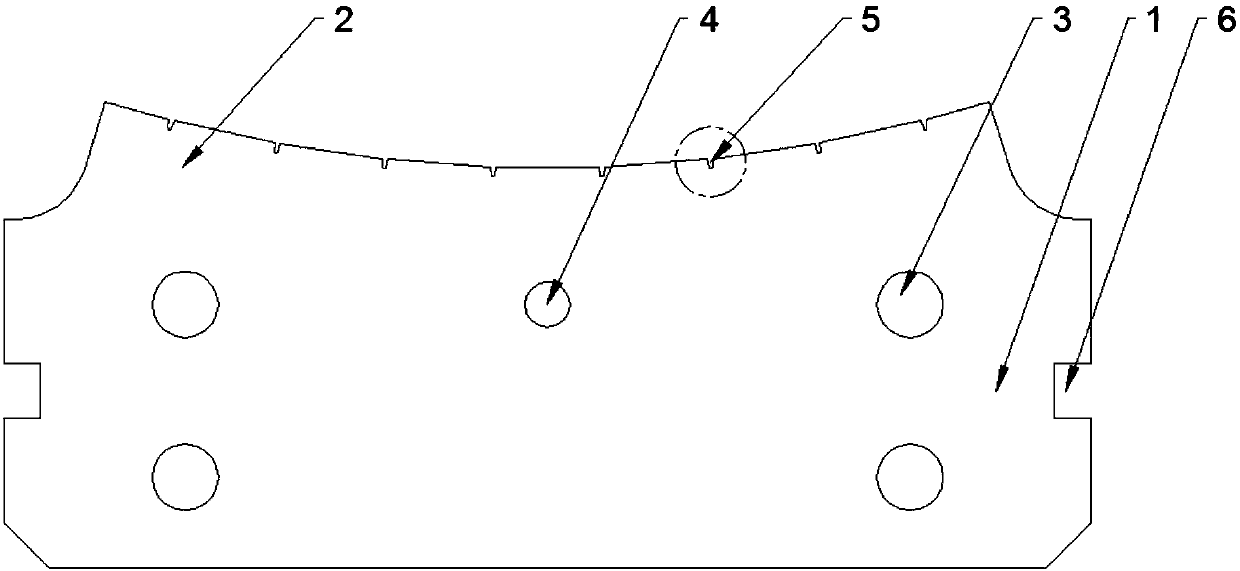

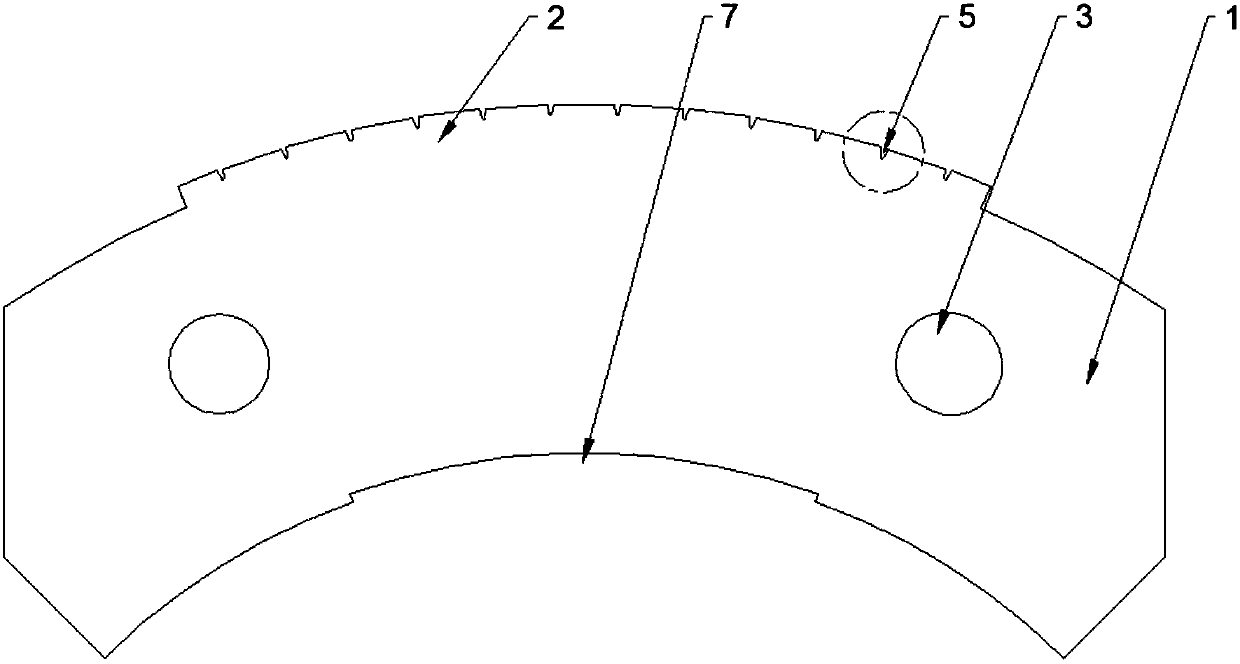

[0121] Such as Figure 5 As shown, the two sides of the knife edge 5 are arc-shaped structures. According to the parameters such as the diameter of the bottle cap and the pulling force required when unscrewing, the optimum parameters of the knife edge 5 are calculated to ensure that the bottle cap 9 can be cut in at an optimum angle. The knife edge 5 increases the cutting area and cutting efficiency while reducing wear on the knife edge 5 and prolongs the service life.

[0122] When the knife edge 5 is partially worn, since the wear conditions of the plurality of knife edges 5 are basically the same, the depth of the bottle cap 9 embedded in the knife edge 2 also basically changes in the same way, and the arc structures on the left and right sides of the knife edge 5 remain the same. The cutting of the bottle cap 9 can be realized, further prolonging the service life.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Caliber | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com