Anti-vibration aluminum profile cutting lathe

An aluminum profile and anti-vibration technology, applied in the field of lathes, can solve problems such as vibration, tool offset, product scrapping, etc., and achieve the effects of precision assurance, convenient operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be further described below in conjunction with examples and comparative examples. The following specific embodiments are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

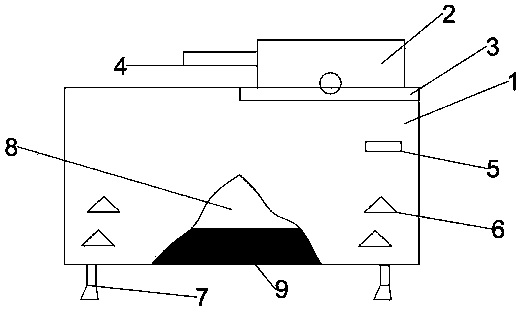

[0028] Such as figure 1 As shown, the technical solution of the present invention is an anti-vibration aluminum profile cutting lathe, including a lathe base 1 and a work table 2. The upper surface of the lathe base 1 is provided with a rail 3, and the work table 2 is provided with a rail 3 mating connecting parts, the workbench 2 is slidably arranged on the rail 3 through the connecting parts, the lathe base 1 is provided with a cavity 8, the shape of the cavity 8 is an isosceles triangle, the isosceles The three sides of the triangular cavity are all wavy shapes, plastic foam balls 9 are arranged inside the cavity, and a tool holder 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com