Martensite steel 3D free-bending forming device and method

A martensitic steel, bending forming technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of inability to achieve free bending, low bending radius accuracy, surface coating damage, etc., to achieve small deformation, High deformation accuracy, rapid and uniform quenching and forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

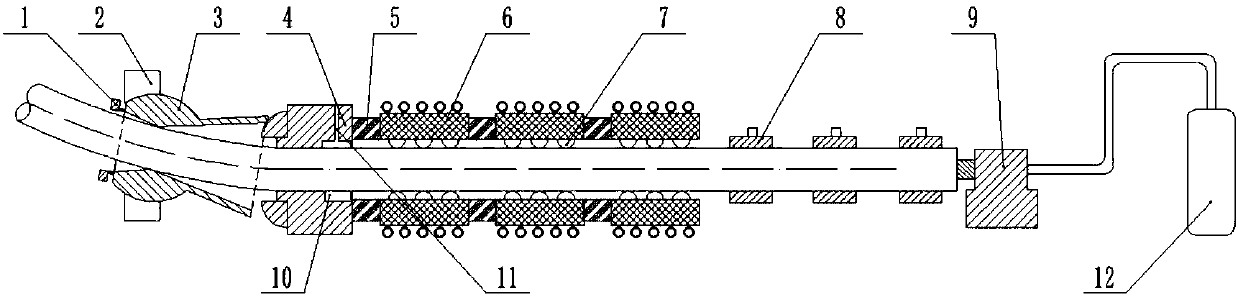

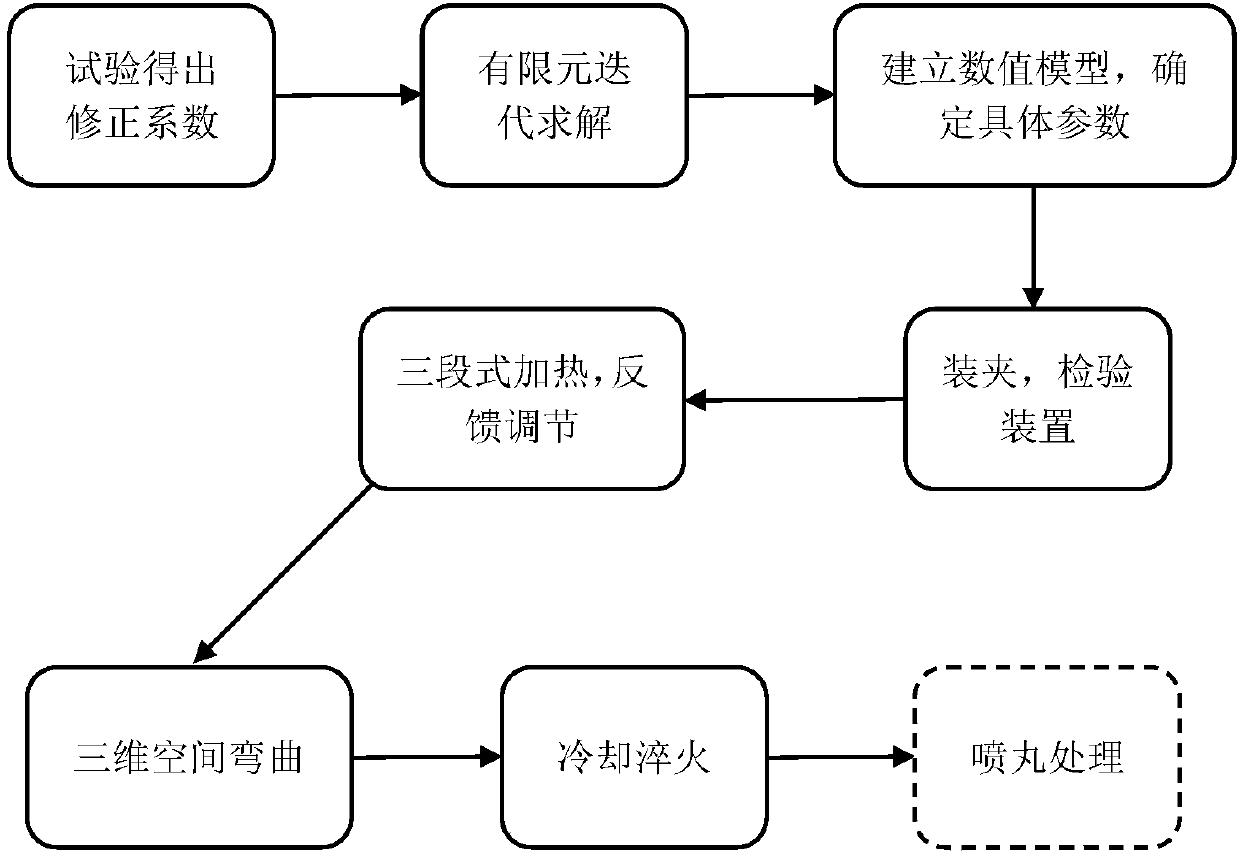

[0044] Refer to attached figure 1 , 2 , 3, a martensitic steel 3D free bending forming device and method, comprising the following steps:

[0045] Parameter determination: select 22MnB5 ultra-high-strength steel pipe with a length of 700mm, a diameter of 25mm, and a wall thickness of 1.5mm to optimize the process parameter setting. After the finite element iterative processing is completed, the corresponding correction coefficients k and k' should be within 1% of the error 1.3 and 1.65 respectively;

[0046] The process of determining the correction coefficient is as follows: before quenching, scan the shape of the newly bent pipe with a 3D scanner, then open the nozzle for rapid quenching, and scan the shape of the parts that have rebound effects after quenching. Export the data to the analysis software, establish a numerical model again for comparison, set the initial value of the material correction coefficient iteration to 1, and calculate the corresponding springback co...

Embodiment 2

[0055] Refer to attached figure 1 , 2 , 3, a martensitic steel 3D free bending forming device and method, comprising the following steps:

[0056] Parameter determination: select the 30MnB5 ultra-high strength steel pipe with a length of 600mm, a diameter of 30mm, and a wall thickness of 2mm to optimize the process parameter setting. After the finite element iterative processing is completed, the corresponding correction coefficients k and k' are respectively under the condition that the error is not greater than 1%. 1.2 and 1.98;

[0057] 1) Clamping: Insert the pipe into the propulsion device 9, use the clamping device 8 to determine its stability in the X, Y and Z directions, and perform a test push operation to verify whether the guide wheel is working normally; open the propulsion mechanism, and place the pipe Try pushing it into the induction heating device 6 with a fixed thrust of 1kN to test whether the transport guide wheel 7 has the effect of reducing the friction ...

Embodiment 3

[0063] Refer to attached figure 1 , 2 , 3, a martensitic steel 3D free bending forming device and method, comprising the following steps:

[0064] Parameter determination: 30CrMnSiA ultra-high strength steel pipe with a length of 650mm, a diameter of 20mm, and a wall thickness of 1.3mm with pure zinc coating is selected for process parameter setting optimization. After the finite element iterative processing is completed, the corresponding correction coefficient is when the error is not greater than 1%. k and k' are 1.16 and 1.34 respectively;

[0065] 1) Clamping: Insert the pipe into the propulsion device 9, use the clamping device 8 to determine its stability in the X, Y and Z directions, and perform a test push operation to verify whether the guide wheel is working normally; open the propulsion mechanism, and place the pipe Try pushing it into the induction heating device 6 with a fixed thrust of 1kN to test whether the transport guide wheel 7 has the effect of reducing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com