High-efficiency atomization desulfurization device and method

A desulfurization device and high-efficiency technology, applied in the field of high-efficiency atomization desulfurization device and high-efficiency atomization desulfurization, can solve the problems of poor scorchability of raw meal, high temperature of sintering zone, and high sulfur-alkali ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

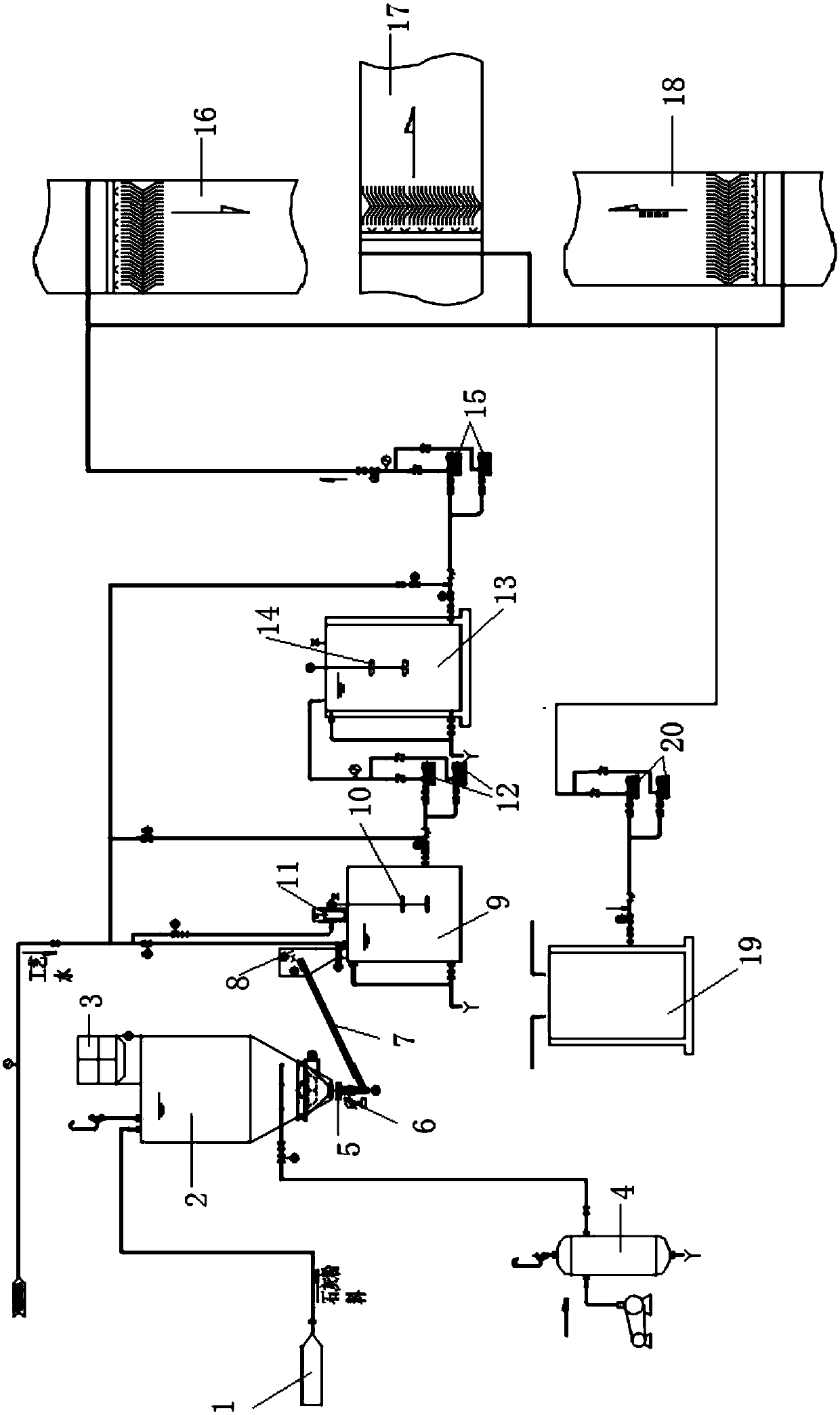

[0087] Such as figure 2 As shown, the present invention provides a kind of NSDD—new material high-efficiency atomization desulfurization device, comprising lime powder feeding and storage system (comprising lime powder tank car 1, lime powder storehouse 2, dust collector 3), lime slurry preparation system (comprising digestion tank 9. Digester tank agitator 10, wet dust collector 11), lime slurry transfer system (slaked lime slurry transfer pump 12), lime slurry storage system (storage tank 13, storage tank agitator 14), lime slurry injection system (slaked lime slurry transport pump 15, humidifying tower 16, raw meal mill 17, preheater 18, humidifying tower 16, raw meal mill 17 and preheater 18 are equipped with spray guns), desulfurization catalyst storage system (catalyst tank 19), desulfurization Catalyst injection system (catalyst delivery pump 20, preheater 18), compressed air system (compressed air storage tank 4) and other components.

[0088] There is a feeding port o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com