Processing method of ready-to-eat salmon

A processing method, salmon technology, applied in food ingredients as antimicrobial preservation, food science, food ingredients, etc., can solve the problems of ineffective addition of medicine, poor food safety, blandness, etc., and achieve high social and economic benefits and Practical value, reduce processing cost, and reduce tissue damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

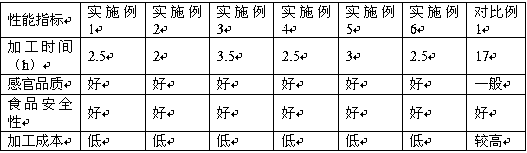

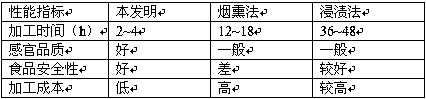

Examples

Embodiment 1

[0045] (1) Rinse the fresh live salmon, put it dormant in cold water at 5°C for 10 minutes, put it on the slaughter table, cut it open with a knife from the middle of the belly, remove the internal organs, wash away the blood and dirt, and drain for 20 minutes;

[0046] (2) Cut salmon fillets from the back of the gill cover to the tail, and cut them into small pieces. Rinse the fish fillets with water, stir them slowly, and then let them stand for 4 minutes. After washing, rinse them with salt water, let them stand for 6 minutes, and then drain them. Dry; the size of the salmon fillet is 5cm×4cm, and the thickness is 0.6cm; the amount of salt added to the salt water is 0.1% of the weight of the fish fillet;

[0047] (3) Prepare the cooking material, put the fish fillets and cook for 40 minutes on medium heat; the ingredients in the cooking material are in parts by weight, including 81 parts of water, 5 parts of sucrose, 3 parts of salt, 5 parts of soy sauce, and 0.05 parts of m...

Embodiment 2

[0053] (1) Rinse the fresh live salmon, rest in cold water at 4°C for 12 minutes, put it on the slaughter table, cut open from the middle of the belly of the fish, remove the internal organs, wash away the blood and dirt, and drain for 18 minutes;

[0054] (2) Cut salmon fillets from the back of the gill cover to the tail, and cut them into small pieces. Rinse the fish fillets with water, stir them slowly, and then let them stand for 5 minutes. After washing, rinse them with salt water, let them stand for 5 minutes, and then drain them. Dry; the size of the salmon fillet is 3cm×2cm, and the thickness is 0.4cm; the amount of salt added to the salt water is 0.2% of the weight of the fish fillet;

[0055] (3) Prepare the cooking material, put the fish fillets into it and cook on medium heat for 32 minutes; the ingredients in the cooking material are in parts by weight, including 84 parts of water, 5 parts of sucrose, 3 parts of salt, 3 parts of soy sauce, and 0.03 parts of monosod...

Embodiment 3

[0061] (1) Rinse the fresh salmon, put it dormant in cold water at 5°C for 20 minutes, put it on the slaughter table, cut it open with a knife from the middle of the belly, remove the internal organs, wash away the blood and dirt, and drain for 18 minutes;

[0062] (2) Cut salmon fillets from the back of the gill cover to the tail, and cut them into small pieces. Rinse the fillets with water, stir them slowly, and then let them stand for 6 minutes. After washing, rinse them with salt water, let them stand for 4 minutes, and then drain. Dry; the size of the salmon fillet is 4cm×2cm, and the thickness is 0.5cm; the amount of salt added to the salt water is 0.1% of the weight of the fish fillet;

[0063] (3) Prepare the cooking material, put the fish fillets into it and cook on medium heat for 37 minutes; the ingredients in the cooking material are in parts by weight, including 83 parts of water, 3 parts of sucrose, 2.95 parts of salt, 3 parts of soy sauce, and 0.05 parts of monos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com