3D printer model withdrawing apparatus

A technology of printer models and 3D printers, applied in 3D object support structures, metal processing equipment, manufacturing tools, etc., can solve problems such as affecting the original effect of the model, low degree of automation, reducing work efficiency, etc., to reduce artificial extrusion, The high degree of automation and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

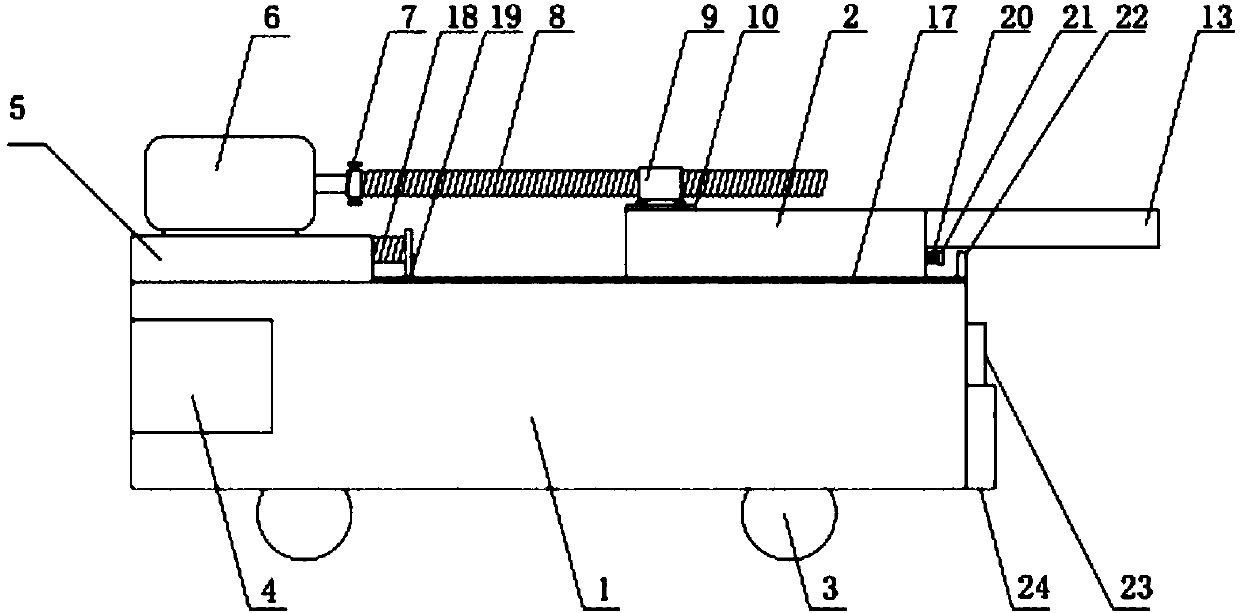

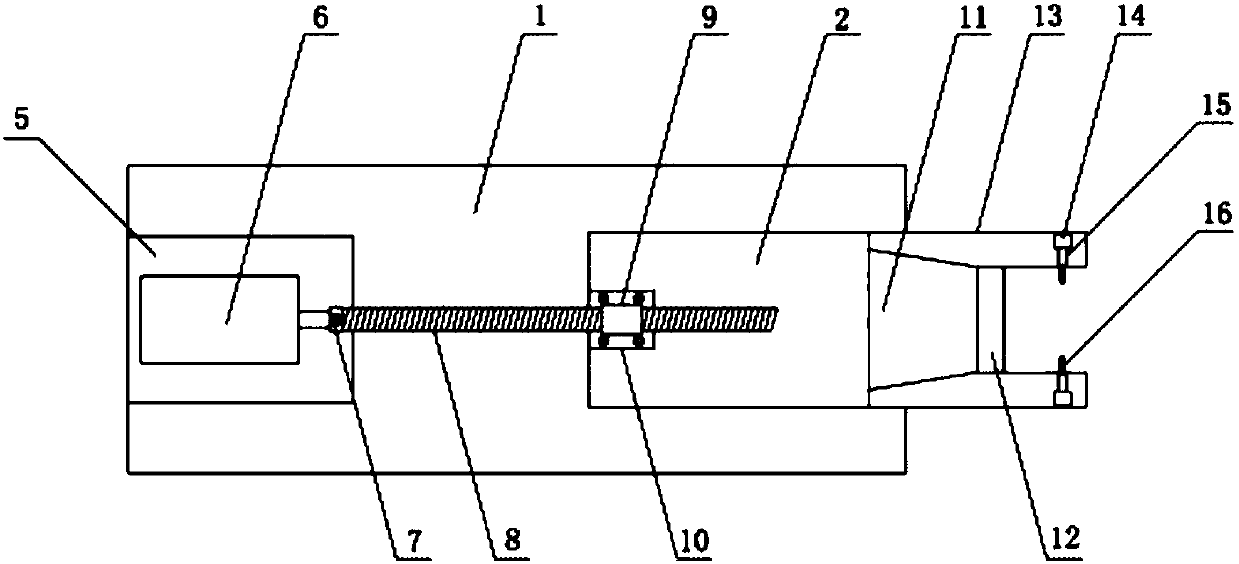

[0018] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] refer to Figure 1-2 , the 3D printer model take-out device described in this specific embodiment includes a cart body 1 and a trolley body 2 arranged on the upper front end of the cart body 1, rollers 3 are installed on the bottom of the cart body 1, and a control Device 4, mounting table 5, motor 6, ring 7, screw rod 8, nut 9, fastening plate 10, groove 11, inclined plate 12, bracket plate 13, hydraulic pump 14, hydraulic cylinder 15 and telescopic rod 16, large The middle part of the car body 1 rear end is provided with a controller 4, and the upper part of the cart body 1 rear end is fixedly provided with a mounting table 5, and a motor 6 is installed on the mounting table 5, and the motor 6 is connected to the controller 4 through a wire, and the output shaft of the motor 6 The ring 7 is fixed by bolts, the ring 7 is provided with a screw 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com