Picosecond laser machining equipment

A picosecond laser and processing equipment technology, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve problems such as difficult to deal with curved contours and low cutting efficiency, and achieve the effect of improving processing quality and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

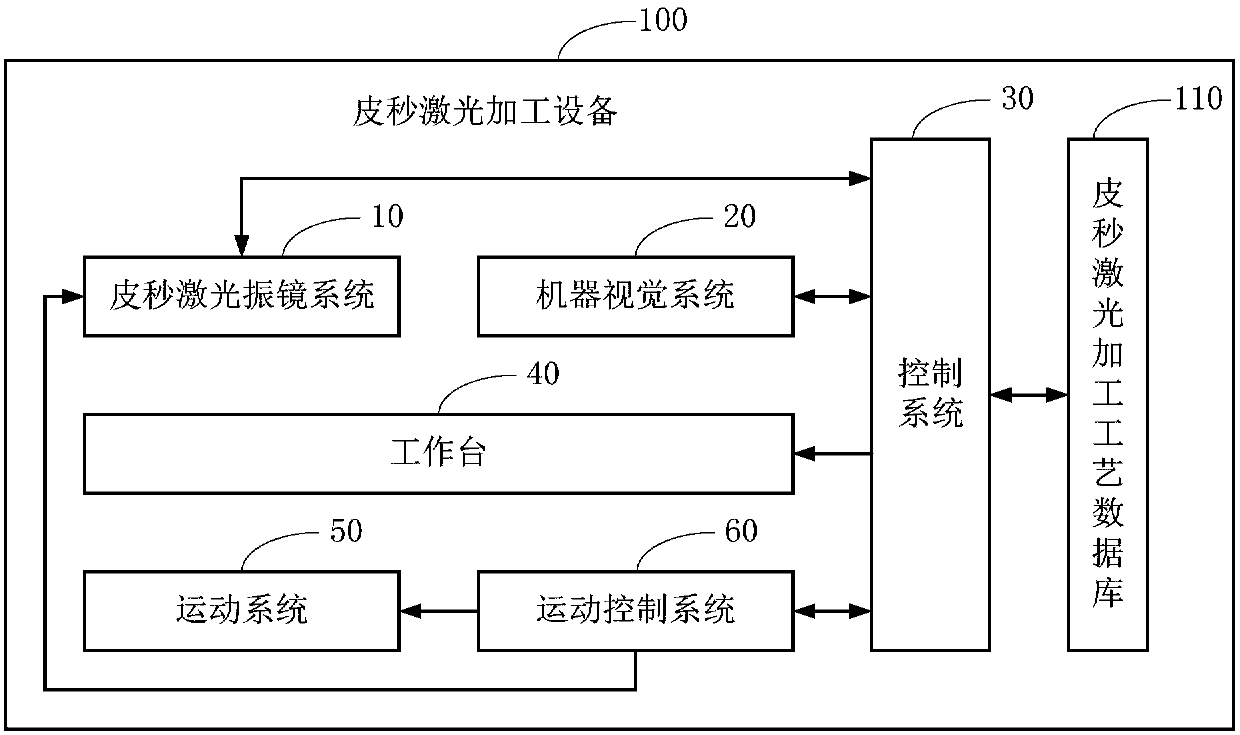

[0038] Such as figure 1 As shown, this embodiment provides a picosecond laser processing equipment 100 , which includes a picosecond laser galvanometer system 10 , a machine vision system 20 , a control system 30 , a workbench 40 , a motion system 50 and a motion control system 60 .

[0039] In one embodiment, the picosecond laser processing equipment also includes a picosecond laser processing technology database stored in the storage device, and the control system calls the data in the picosecond laser processing technology database for the picosecond laser galvanometer system, machine vision system, The working state of the workbench and motion control system is controlled to realize laser precision machining of brittle materials.

[0040] Such as figure 1 As shown, the picosecond laser processing technology database 110 stored in the storage device is exemplarily shown, and the control system 30 can call the data in the picosecond laser processing technology database 110,...

Embodiment 2

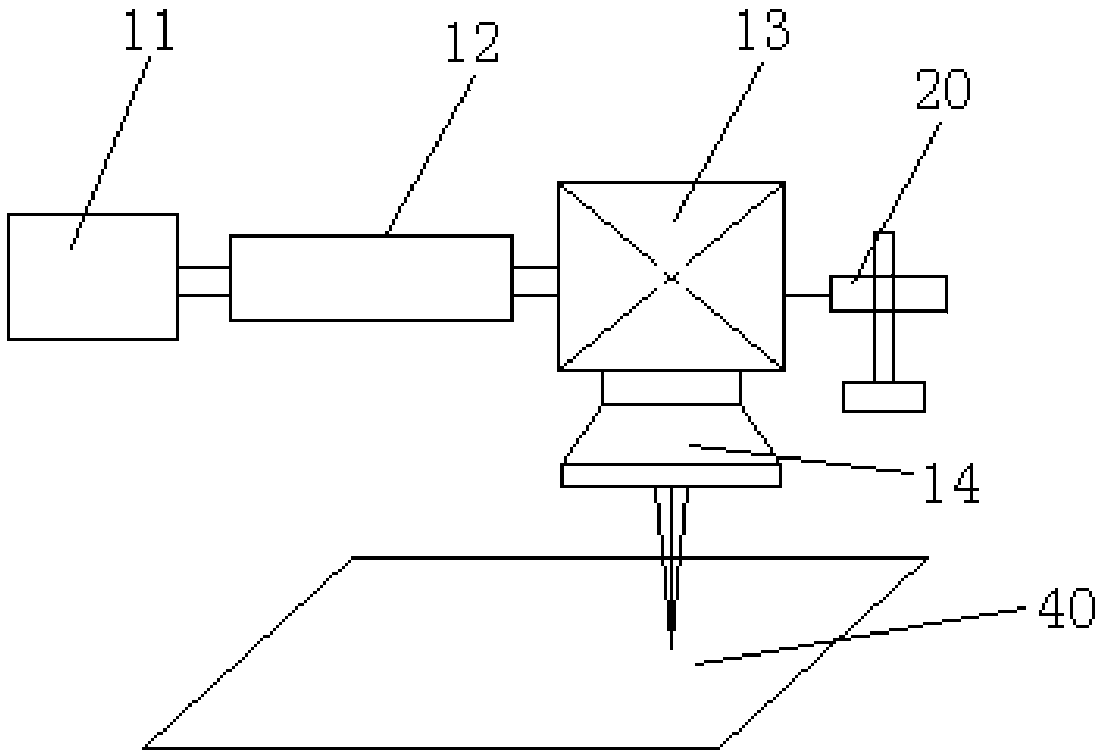

[0068] Such as image 3 As shown, in one embodiment of the present invention, the picosecond laser vibrating mirror system 10 includes a picosecond laser 11, an optical path system 12, a vibrating mirror system 13 and an autofocus system 14, and the optical path system 12 includes at least one mirror (in the figure not shown), the vibrating mirror system 13 includes an X-direction scanning mirror and a Y-direction scanning mirror (not shown in the figure), and the self-focusing system 14 includes at least one focusing lens (not shown in the figure).

[0069] image 3 The relative positional relationship between the systems in the picosecond laser galvanometer system 10 is only exemplarily shown; wherein, the optical path system 12 is arranged on the light exit side of the picosecond laser 11, and the galvanometer system 13 is arranged on the light exit side of the optical path system 12. side, the self-focusing system 14 is set on the light-emitting side of the galvanometer s...

Embodiment 3

[0087] Such as Figure 5 As shown, in one embodiment of the present invention, the optical path system 12 includes a beam expander 121, a first reflector 122, a second reflector 123, a third reflector 124, The fourth reflector 125, the X-direction translation mechanism (not shown in the figure), and the Z-direction lifting mechanism (not shown in the figure).

[0088] Such as Figure 5 As shown, in this embodiment, the beam expander 121 is arranged on the light-emitting side of the picosecond laser 11, and the relative positions of the picosecond laser 11, the beam expander 121, the first reflector 122 and the second reflector 123 are fixed and uniform. Sealed installation, the third reflector 124 is arranged on the X-direction translation mechanism, the fourth reflector 125 is arranged on the Z-direction lifting mechanism, the third reflector 124, the fourth reflector 125, the X-direction translation mechanism and the Z-direction lifting mechanism Arranged in the same seale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com