Electric arc welding method and electric arc welding device

A welding equipment and welding method technology, applied in arc welding equipment, welding equipment, welding accessories and other directions, can solve the problems of reducing welding efficiency, increasing welding cost, unable to weld seam, etc., so as to reduce welding cost and improve welding efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The inventors found that in the prior art, in order to improve the welding efficiency of tungsten arc welding and reduce the welding cost, the following three methods are usually used to weld the weld seam with a relatively large width.

[0029] One, in the specific welding process, the welder moves the welding torch back and forth along the direction perpendicular to the weld seam by swinging his wrist, so that the solder can fall into a wider weld seam range. When the torch is moved from one end of the weld to the other, it improves welding efficiency.

[0030] However, manual control by the welder is highly dependent on the welder, and generally the uniformity of welding cannot be guaranteed, resulting in an unsatisfactory effect in terms of welding quality and welding appearance.

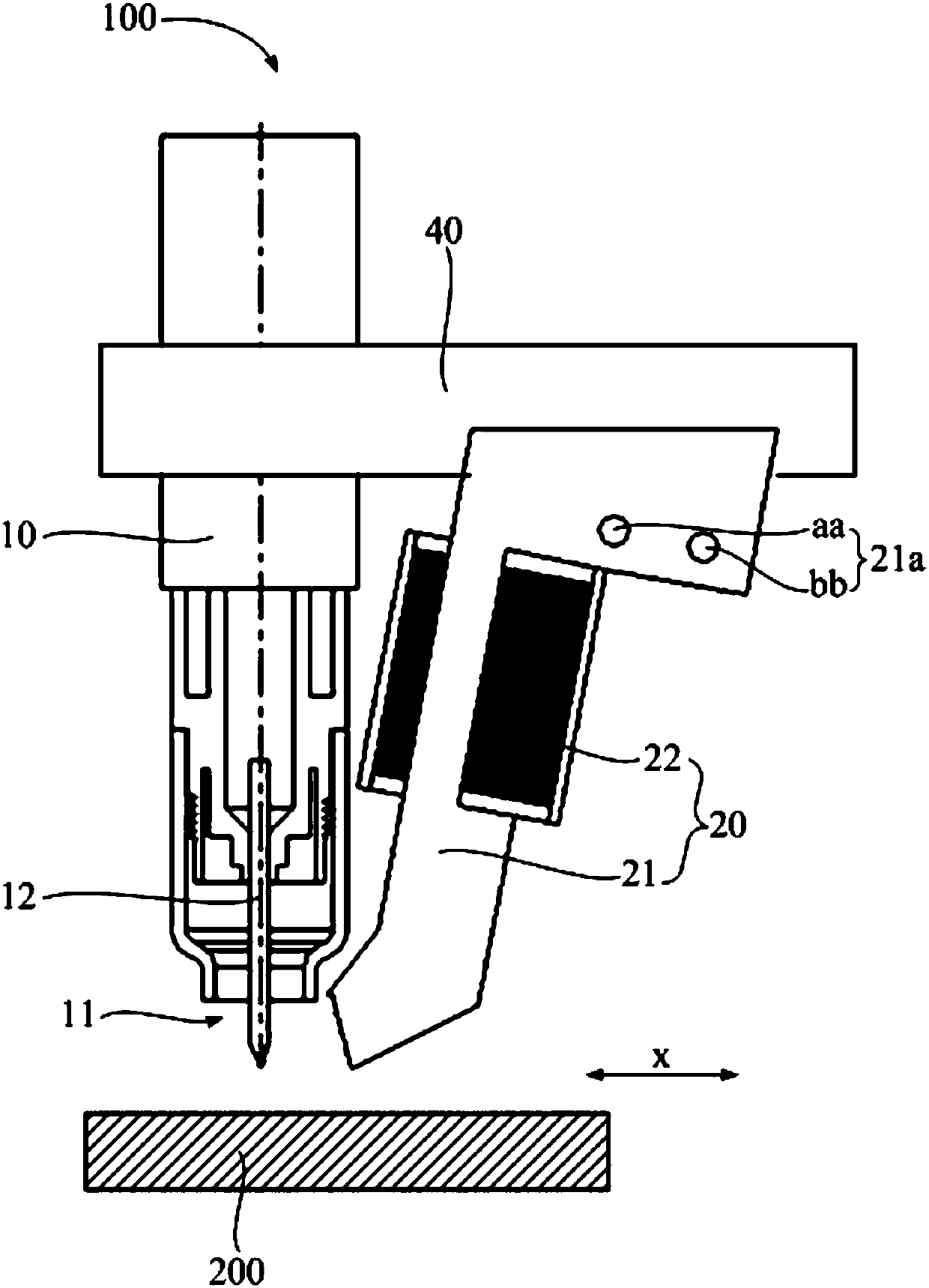

[0031] Second, by setting a mechanical swing structure, the mechanical swing structure is fixedly connected to the welding torch. During the welding process, the welding torch is control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com