Design method of impeller blade drag reduction micro-texture

A technology of impeller blades and design methods, applied in the field of blade drag reduction, can solve the problems of waste of resources and time, lack of pertinence and flexibility, lack of universality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

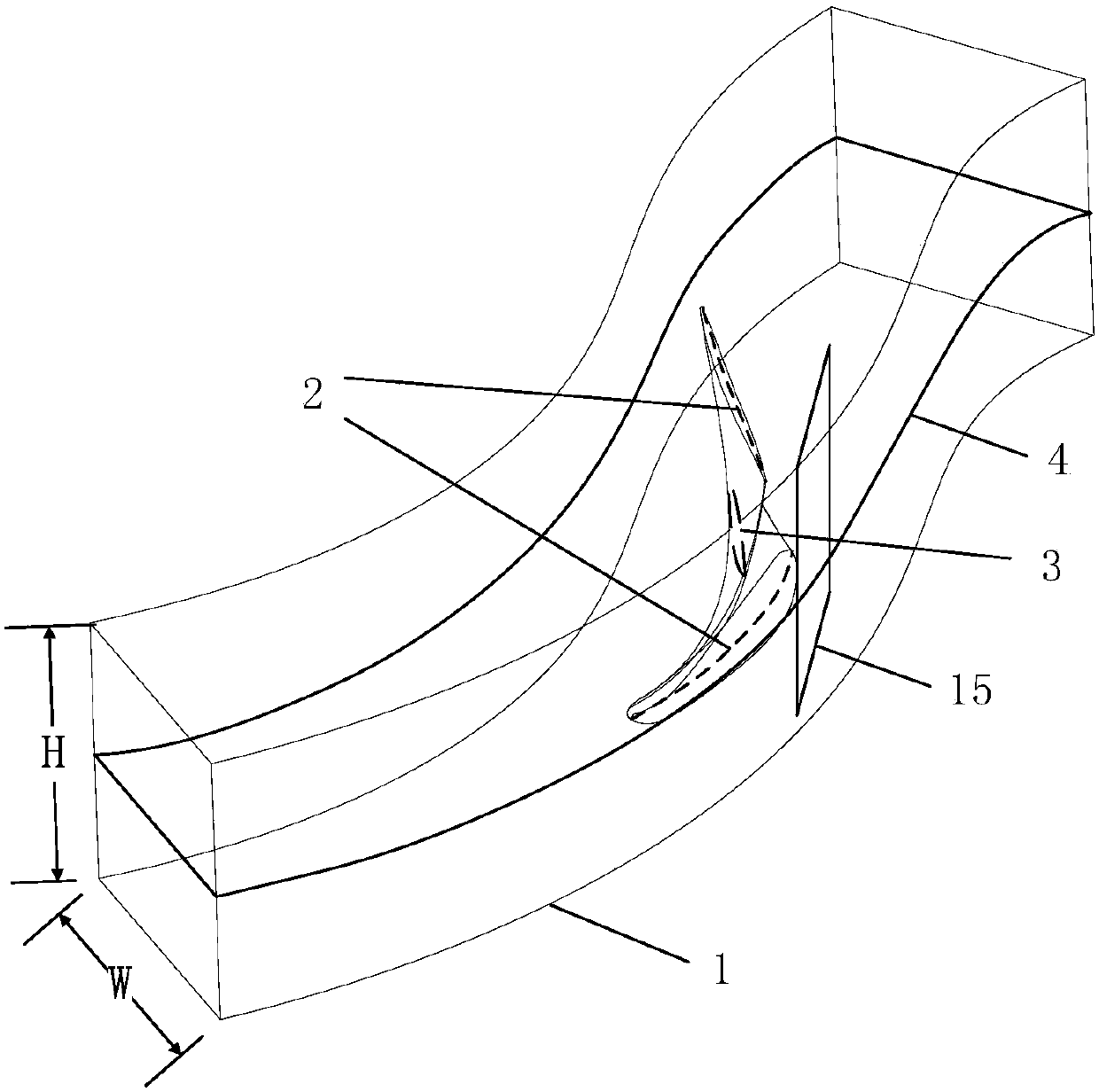

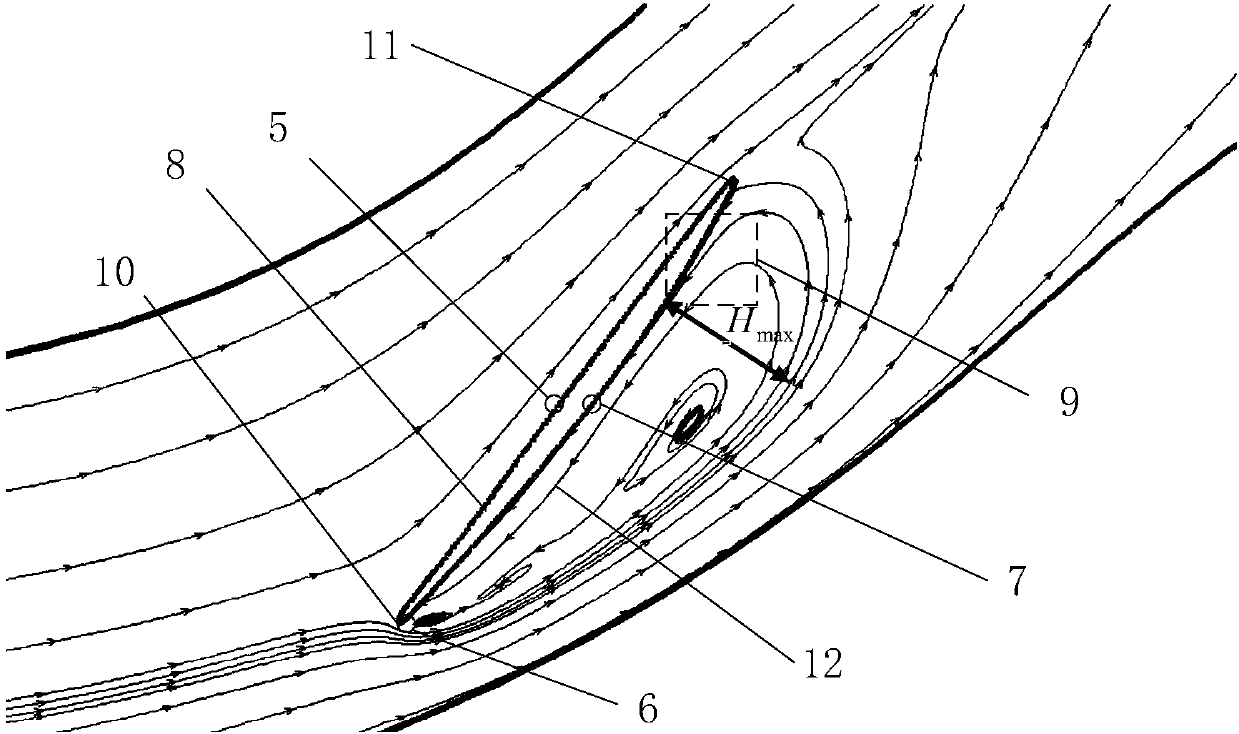

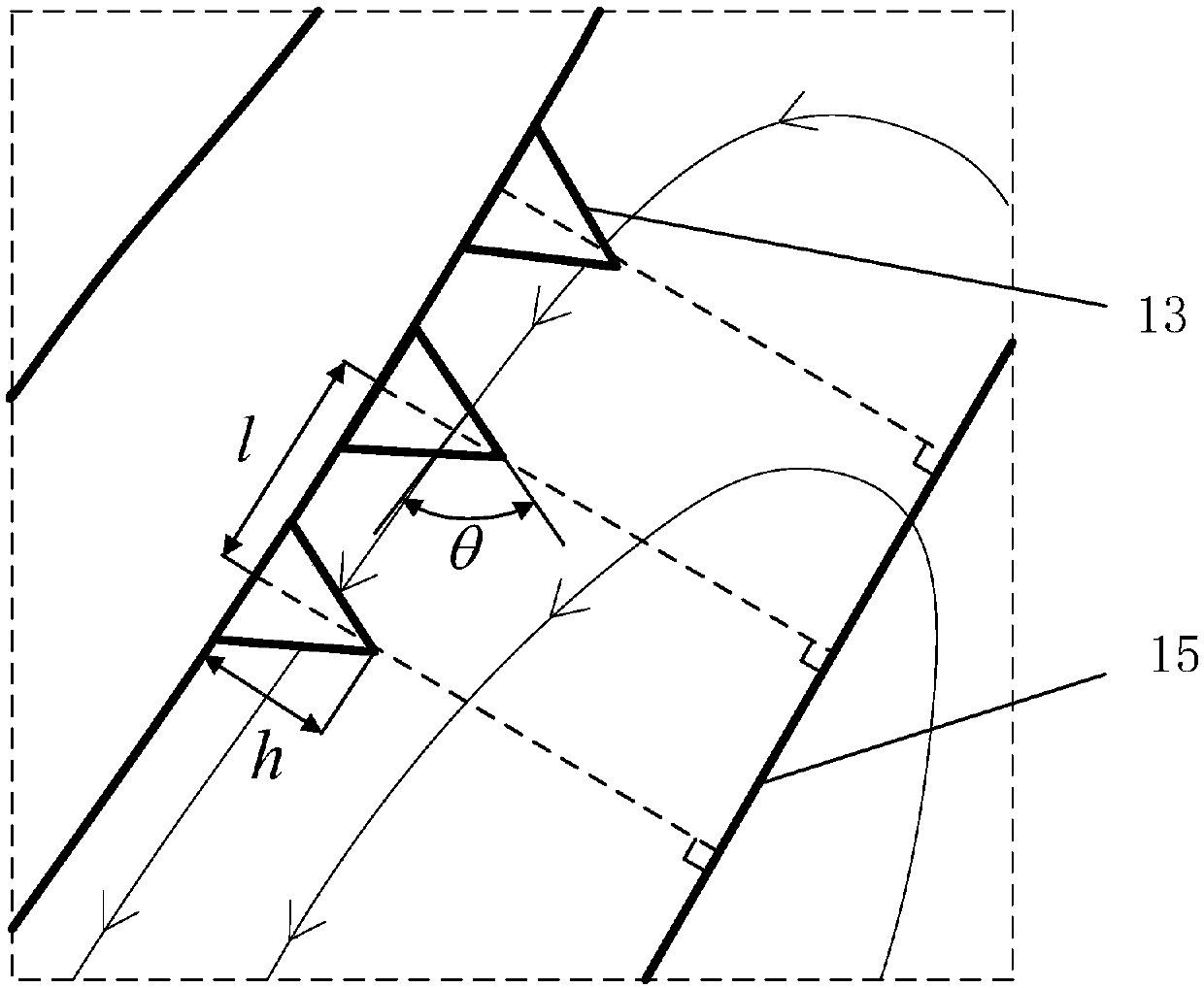

Image

Examples

Embodiment Construction

[0040] Table 1 Point coordinate data of blade example

[0041]

[0042]

[0043]

[0044]

[0045]

[0046]

[0047]

[0048] Table 2 Numerical simulation model parameters

[0049] name

parameter

Inlet speed (m / s)

75

fluid

temperature (k)

300

Turbulence model

k-ε(2eqn); Realizable

wall function

Enhanced Wall Treatment

[0050] Table 3 Experimental results of micro-texture height h and drag reduction effect

[0051] Microtexture height h and H max ratio / %

Drag reduction percentage / %

3.6

3.1

4

5

4.4

6.1

4.8

6

5.2

5.5

5.6

4

6

3.1

6.4

1.1

6.8

0.5

7.2

-1.3

[0052] Table 4 Experimental results of micro-texture center distance l and drag reduction effect

[0053]

[0054]

[0055] Table 5 The experimental results of the angle θ between the upstream edge and the incom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com