Heat pump air conditioner

a technology of heat pump and air conditioner, which is applied in the direction of lighting and heating apparatus, refrigeration components, heating types, etc., can solve the problems of uneven cooling/heating, uneven heating or cooling of air, etc., and achieve stable air conditioning, reduce uneven cooling/heating, and eliminate overshoot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

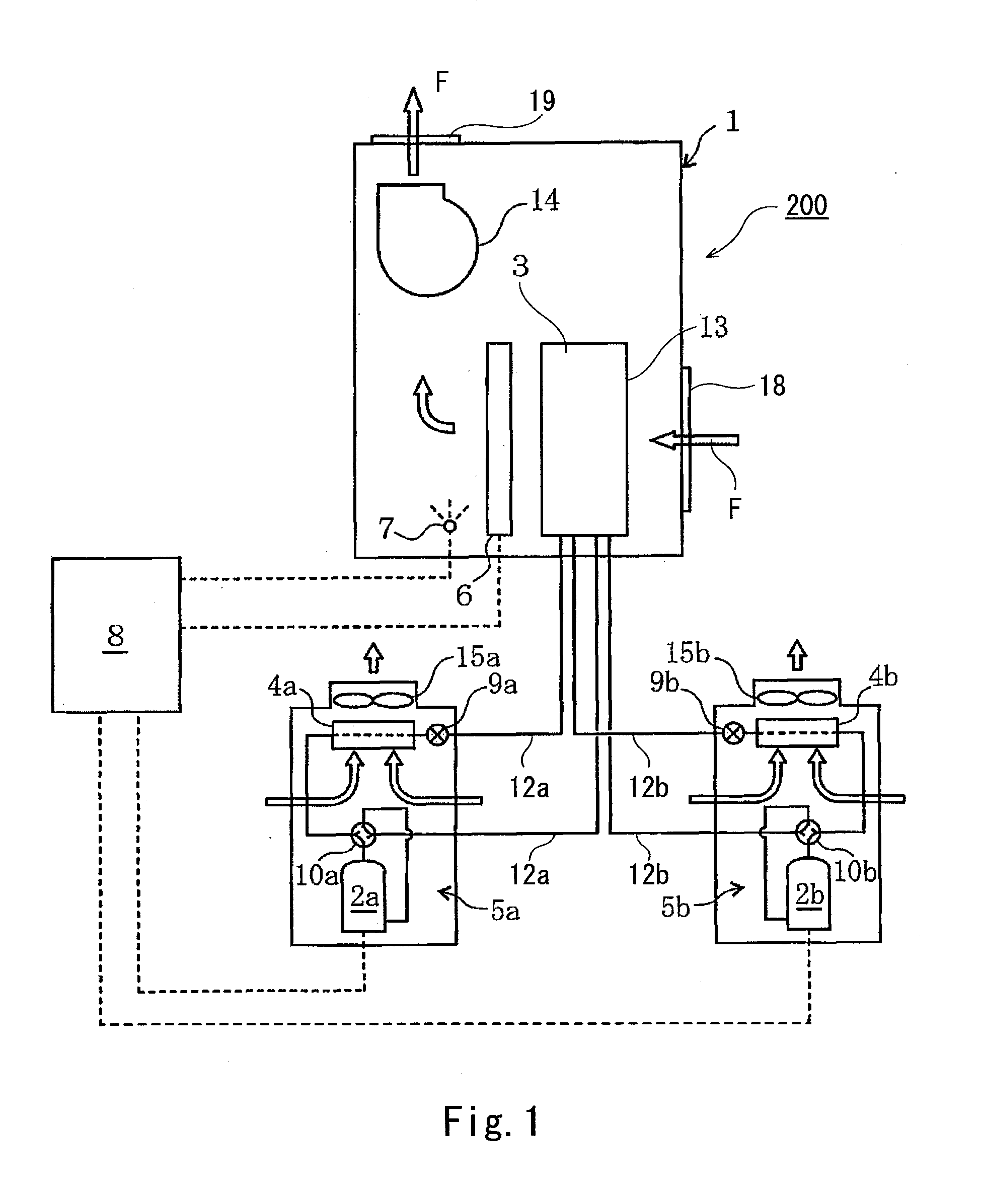

embodiment 1

[0041]The controller 8 includes a microprocessor and various sensors, for example. The controller 8 includes a memory as necessary. The controller 8 stores a reference value for an air-conditioning load applied to the heat pump air conditioner 200. The controller 8 compares the air-conditioning load applied to the heat pump air conditioner 200 with the reference value, switches the state of the first compressor 2a and the second compressor 2b between an operating state and an operation stopped state, and performs output adjustment. Specifically, if the air-conditioning load applied to the heat pump air conditioner 200 is less than the reference value, the controller 8 stops both the compressors 2a and 2b from operating.

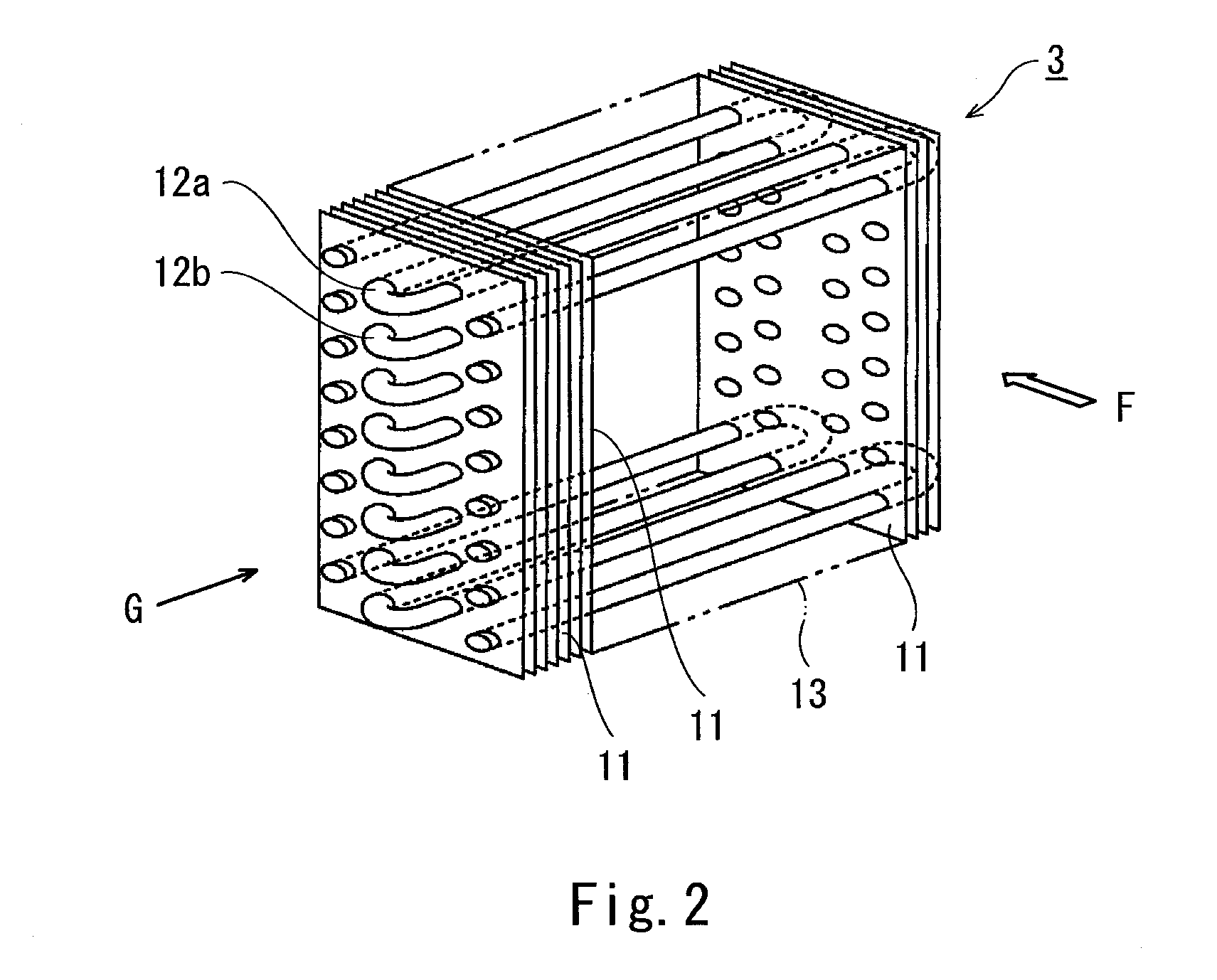

[0042]If the load applied to the heat pump air conditioner 200 is higher than or equal to the reference value and is great, the controller 8 causes both the compressors 2a and 2b to operate, thereby causing the refrigerant to flow into all of the heat transfer pipes 1...

embodiment 2

[0044]If the load applied to the heat pump air conditioner 200 is higher than or equal to the reference value, the controller 8 may cause the first compressor 2a and the second compressor 2b to operate alternately. As a result, the refrigerant flows into the heat transfer pipes 12a and the heat transfer pipes 12b alternately. Specifically, while causing the first compressor 2a to operate, the controller 8 stops the second compressor 2b, thereby stopping the flow of the refrigerant in the second heat transfer pipes 12b, and while stopping the first compressor 2a, the controller 8 causes the second compressor 2b to operate, thereby causing the refrigerant to flow into the heat transfer pipes 12b. The order in which the first compressor 2a and the second compressor 2b are caused to operate alternately may be inverted during the operation. Further, the controller 8 may adopt an operation pattern in which the heat pumps 5a and 5b are sequentially caused, one by one, to start and stop. In...

embodiment 3

[0046]Alternatively, when causing the first compressor 2a and the second compressor 2b to operate alternately, the controller 8 totals either a previous operating time of each of the compressors 2a and 2b or the number of previously performed operations of each of the compressors 2a and 2b. The controller 8 may preferentially cause one of the compressors 2a and 2b with a less previous operating time or a less number of previously performed operations to operate, and may stop the other one of the compressors 2a and 2b with a more previous operating time or a more number of previously performed operations. In this manner, the operation frequency or operating time can be made uniform between the compressors 2a and 2b. This makes it possible to extend the life of the compressors 2a and 2b, and reduce the number of times to repair the compressors 2a and 2b due to breakdown.

[0047]The controller 8 may switch the state of the compressors 2a and 2b between an operating state and an operation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com