Gradient monocrystalline diamond and preparation method thereof

A single crystal diamond, gradient technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of high-quality single crystal diamond easily cracked, low wear resistance of nitrogen-containing diamond, etc., and achieve high hardness , The effect of inhibiting the growth of steps and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

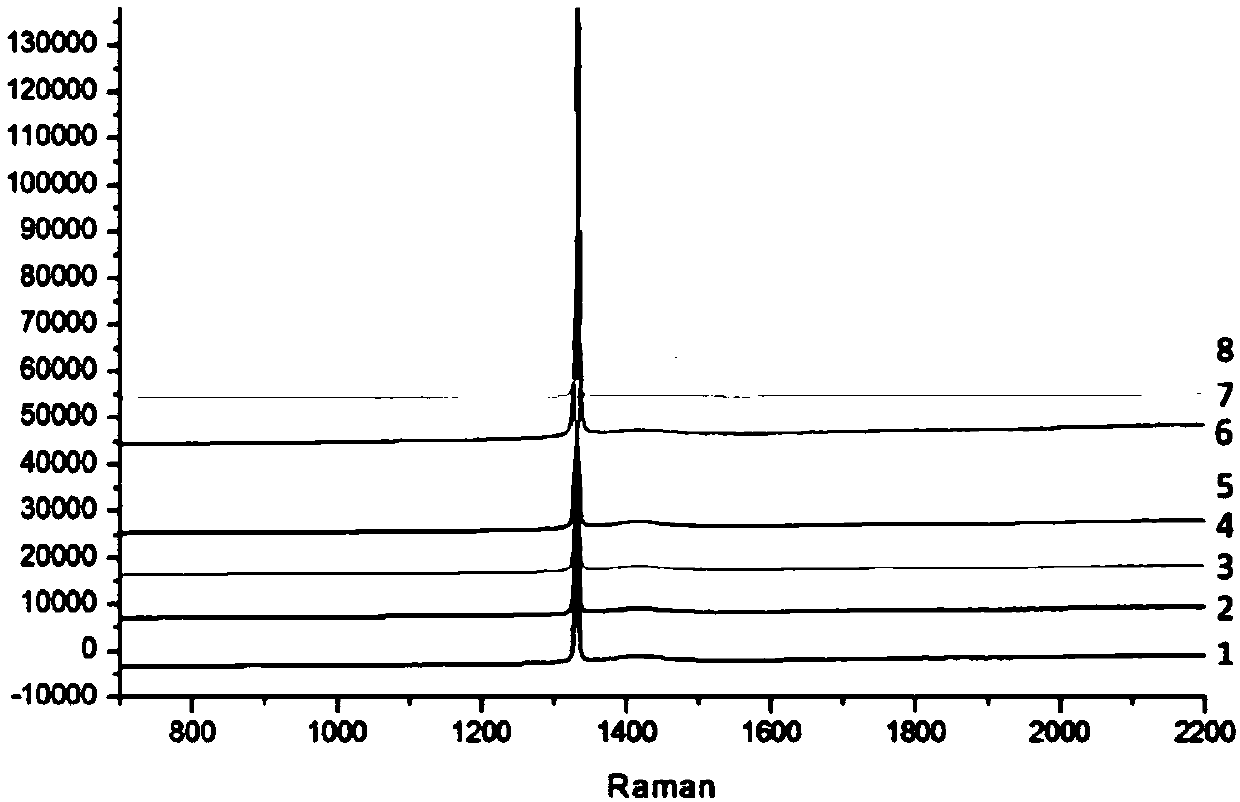

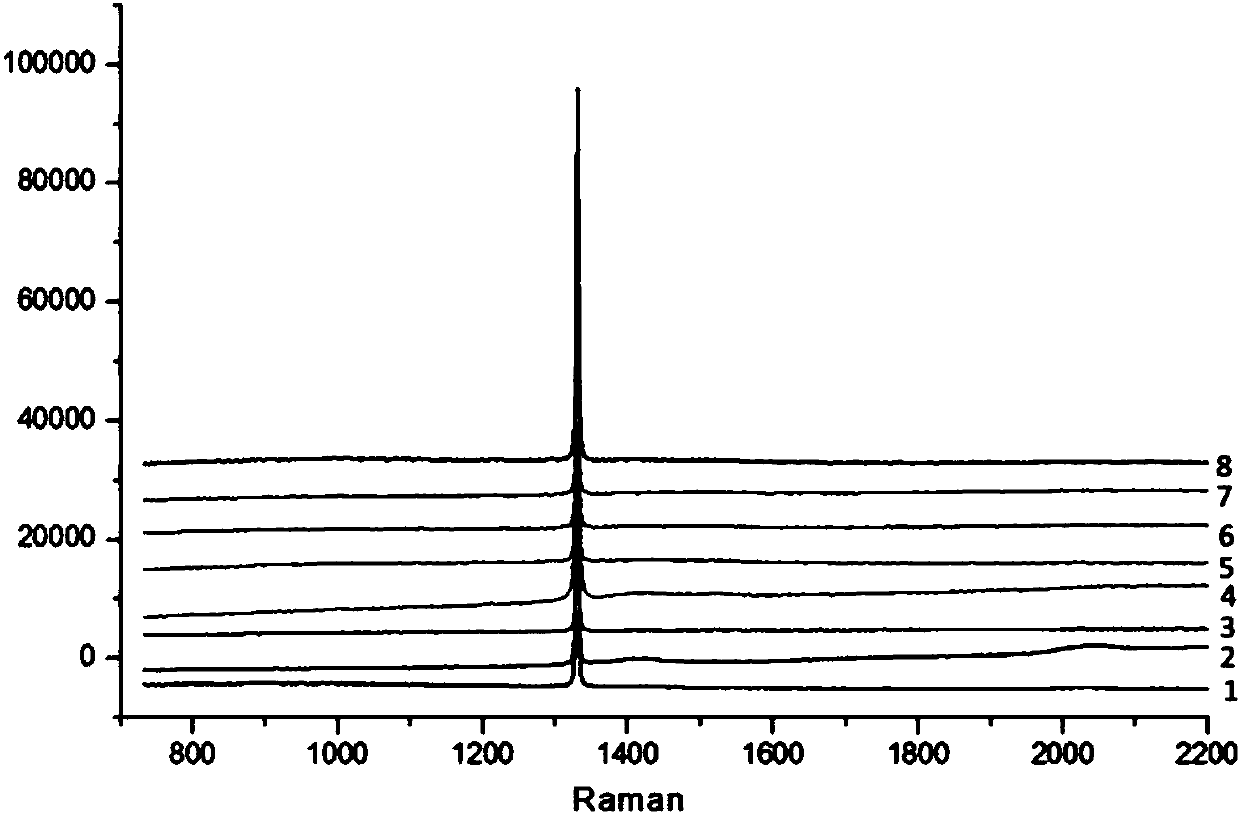

Image

Examples

Embodiment 1

[0044] A method for synthesizing gradient single crystal diamond and its products, comprising: adopting microwave plasma chemical vapor deposition equipment, using a mixed gas source of hydrogen, methane, and high-purity air as a reaction gas into a reaction chamber, and using a working pressure of 20kPa 1. Under the condition of single crystal diamond substrate temperature of 1000°C, high-speed homoepitaxial growth of gradient single crystal diamond is realized. During the gradient single crystal diamond growth process, the flow of hydrogen, methane and high-purity air into the reaction chamber is controlled by a gas flow meter. Hydrogen, methane, and high-purity air are uniformly mixed before entering the reaction chamber. Among them, the feeding method of hydrogen and methane is continuous feeding, and the feeding method of high-purity air is continuous gradient method.

[0045] Further, the specific method of the continuous gradient method is: continuously gradiently cont...

Embodiment 2

[0050] In the present invention, when growing single crystal diamond, a certain concentration of high-purity air is mixed into the mixed gas source of hydrogen and methane, nitrogen can increase the growth rate of single crystal diamond, oxygen can improve the growth quality of single crystal diamond, and the continuous gradient method controls the mixing of hydrogen The concentration ratio of high-purity air in the methane mixed gas source can realize the gradient change of single crystal diamond quality. On the premise of ensuring the high speed and high hardness growth of single crystal diamond, it can also improve the toughness of single crystal diamond and greatly improve the wear resistance of single crystal diamond.

[0051] A method for growing single crystal diamond at a high speed in the present invention, comprising: controlling the working pressure of single crystal diamond growth to 16.8kPa; controlling the working temperature of single crystal diamond to 980°C; O...

Embodiment 3

[0056] Example 3 Effect of high-purity air composition on the quality of gradient single crystal diamond

[0057] Change the composition of high-purity air, including see Table 1 according to volume percentage, others are the same as in Example 2, compare with Comparative Example 1-5, the comparison of the number of workpieces processed by diamond tools is shown in Table 1, and it can be seen from Table 1 that nitrogen and oxygen in high-purity air The ratio of nitrogen to oxygen is a specific range interval. When the ratio of nitrogen to oxygen is close to 4:1, the number of processing is the best. This is because the ratio of nitrogen atoms to oxygen atoms is too high to reduce the hardness of single crystal diamond, and the ratio is too low. It will lead to a decrease in the overall strength of the material, thereby affecting the processing performance of the tool, while less carbon dioxide, argon and water vapor have less impact on the product.

[0058] Table 1 Effect of h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com