Method and device for deeply treating wastewater by coupling PVDF/ZnO piezoelectric ultrafiltration membrane to advanced oxidation technology

An advanced oxidation technology and advanced treatment technology, which is applied in the field of PVDF/ZnO piezoelectric ultrafiltration membrane coupling advanced oxidation technology advanced treatment of wastewater, can solve the problems of increased conductivity, large influence, and limited application area, etc., to improve the service life of the membrane , Improve the quality of effluent water and reduce the effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

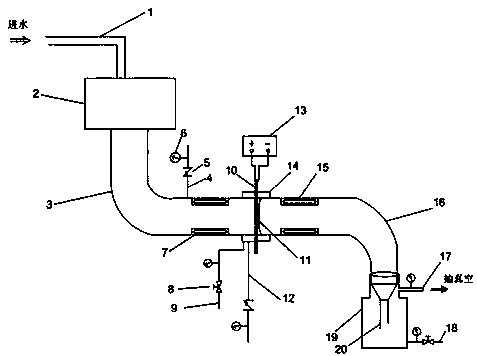

Image

Examples

Embodiment 1

[0024] Example 1: The PVDF / ZnO piezoelectric ultrafiltration membrane is prepared by a conventional phase inversion method to obtain a PVDF / ZnO ultrafiltration membrane with a thickness of 500 μm. It is obtained by 8KV DC high-voltage polarization for 120 minutes under vacuum conditions at 40°C. The specific preparation Methods as below:

[0025] Add nano-ZnO to the NMP solvent, ultrasonic 1h, and magnetically stir for 1h, so that the nano-ZnO is evenly dispersed in the NMP solvent. At this time, PVDF powder is added to the NMP solvent mixed with nano-ZnO. The mass ratio of PVDF powder to nano-ZnO is 2:1, wherein the total mass of PVDF and nano-ZnO accounted for 15% of the total mass of the casting solution, mechanically stirred in a water bath at 30°C for 8 hours, and then stood in a vacuum environment for 12 hours for defoaming treatment to obtain the casting solution; The film scraping machine evenly distributes the casting solution on the glass plate to form a film, bakes ...

Embodiment 2

[0033] Example 2: The PVDF / ZnO piezoelectric ultrafiltration membrane is prepared by a conventional phase inversion method to obtain a PVDF / ZnO ultrafiltration membrane with a thickness of 750 μm. It is obtained by 15KV DC high-voltage polarization for 90 minutes under vacuum conditions at 50°C. The specific steps Referring to Example 1, during preparation, the mass ratio of PVDF powder to nano-ZnO was 1.5:1, wherein the total mass of PVDF and nano-ZnO accounted for 18% of the total mass of the casting liquid, the solvent was DMAc, and the extractant was absolute ethanol.

[0034] Utilize PVDF / ZnO piezoelectric ultrafiltration membrane coupled with advanced oxidation technology for advanced treatment of wastewater, pass the untreated wastewater and ozone through PVDF / ZnO piezoelectric ultrafiltration membrane, and the concentration of ozone introduced is 6g / (L h), PVDF / ZnO The piezoelectric ultrafiltration membrane is connected to an AC power supply to provide a transmembrane p...

Embodiment 3

[0041] Example 3: The PVDF / ZnO piezoelectric ultrafiltration membrane is prepared by a conventional phase inversion method to obtain a PVDF / ZnO ultrafiltration membrane with a thickness of 1000 μm. It is obtained by 20KV DC high-voltage polarization for 40 minutes under vacuum conditions at 45°C. The specific steps Referring to Example 1, during preparation, the mass ratio of PVDF powder to nano-ZnO is 3:1, wherein the total mass of PVDF and nano-ZnO accounts for 30% of the total mass of the casting liquid, the solvent is DMF, and the extractant is absolute ethanol.

[0042] Utilize PVDF / ZnO piezoelectric ultrafiltration membrane coupled with advanced oxidation technology for advanced treatment of wastewater, pass the untreated wastewater and ozone through PVDF / ZnO piezoelectric ultrafiltration membrane, the concentration of ozone introduced is 8g / (L h), PVDF / ZnO The piezoelectric ultrafiltration membrane is connected to an AC power supply to provide a transmembrane pressure in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com