Anaerobic online acid washing device

A pickling and line acid technology, which is applied in anaerobic digestion treatment, cleaning hollow objects, water treatment parameter control, etc., can solve the problems of large fluctuations in water output, fluctuations in biochemical loads, and reduced processing capacity, so as to improve the safety of use High performance, convenient maintenance of equipment, prolonging the effect of using time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

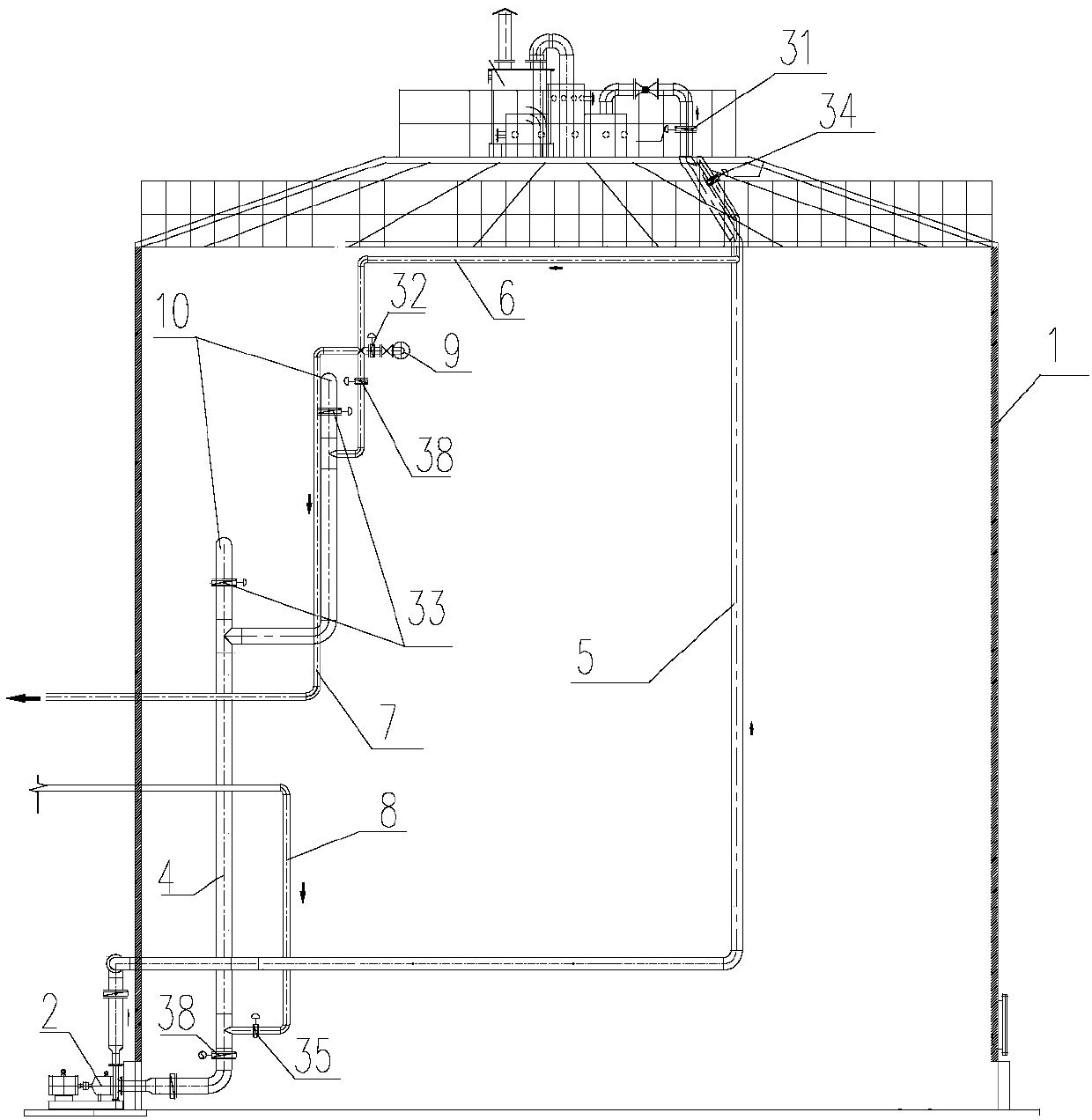

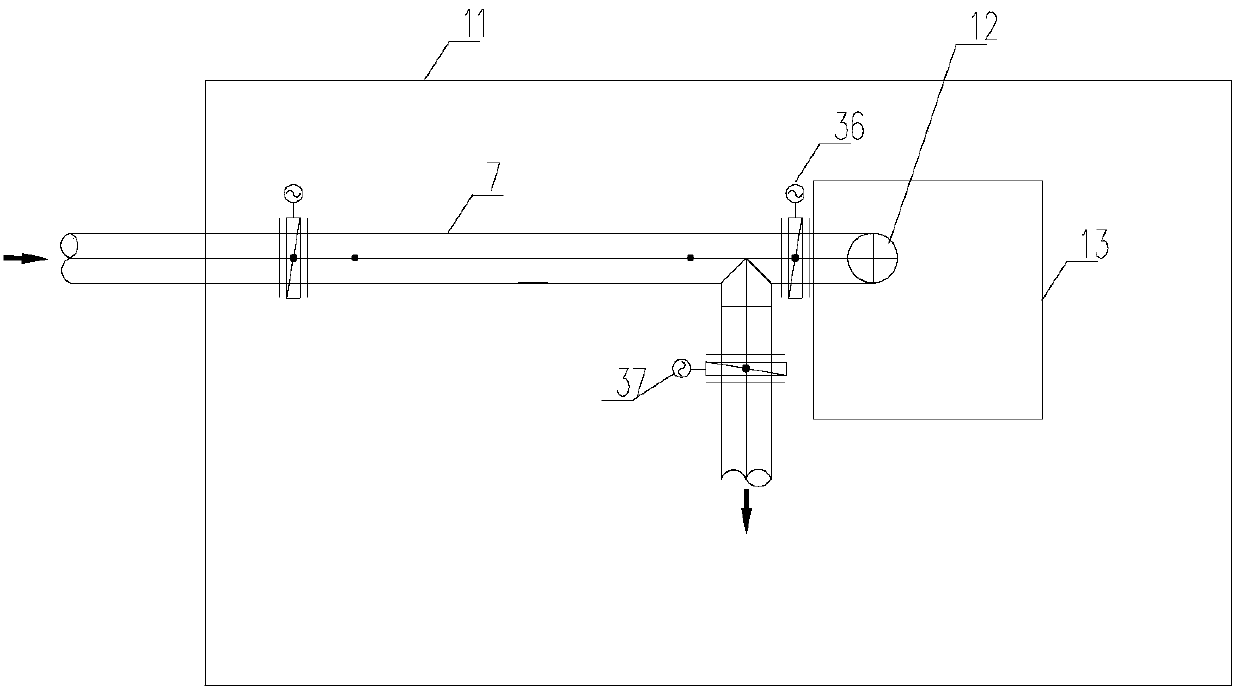

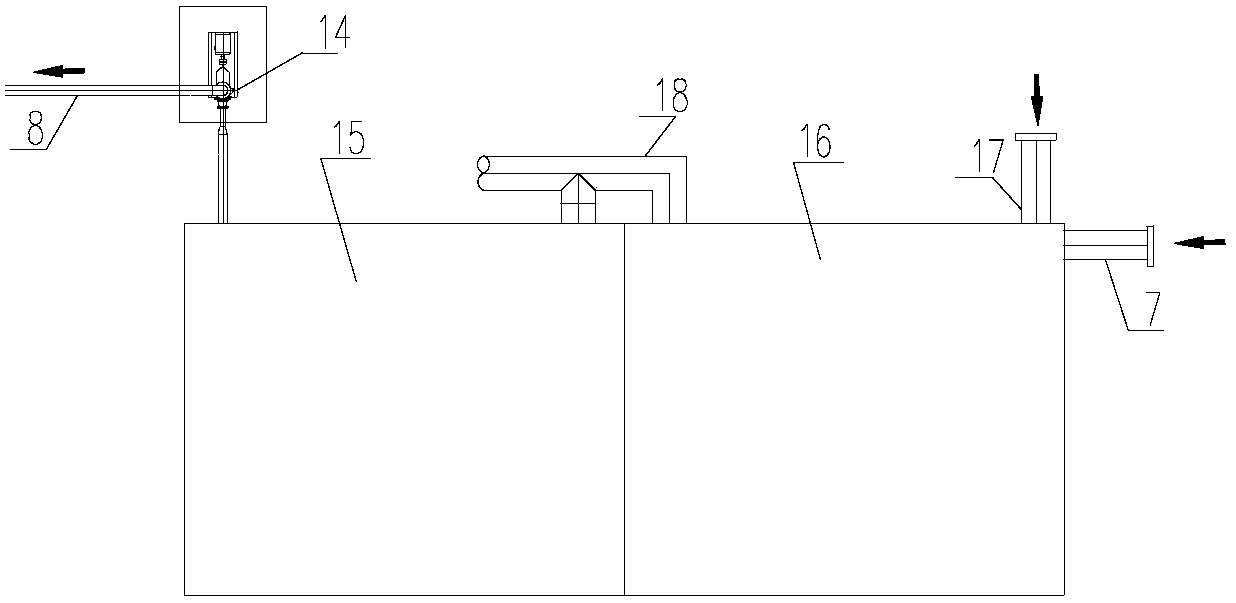

[0021] refer to figure 1 , figure 2 , image 3 , an anaerobic on-line pickling device proposed by the present invention, a first valve 31 is provided at one end of the circulating pump outlet pipe 5 connected to the anaerobic reactor 1, and a first valve 31 is provided at one end of the anaerobic outlet pipe 7 connected to the anaerobic reactor 1. Two valves 32, and a third valve 33 is provided at the input port of the water inlet pipe 4 of the circulating pump.

[0022] The circulation pump outlet pipe 5 and the anaerobic outlet pipe 7 are connected through the pre-installed pickling circulation pipe 6, and the circulation pump inlet pipe 4 is connected with the pickling water inlet pipe 8. The pickling circulation pipe 6 is provided with a fourth valve 34 , and the pickling water inlet pipe 8 is provided with a fifth valve 35 .

[0023] Thus, in this embodiment, when the fourth valve 34 and the fifth valve 35 are closed, and the first valve 31, the second valve 32 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com