Positioning device of PA nylon stick

A positioning device and nylon rod technology, which is applied in metal processing and other directions, can solve the problems of nylon rod surface slippery, poor clamping, cost waste, etc., and achieve the effects of smooth movement, improved production efficiency, and reduced cost waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

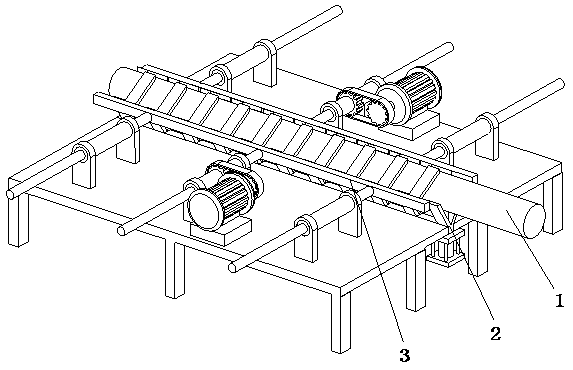

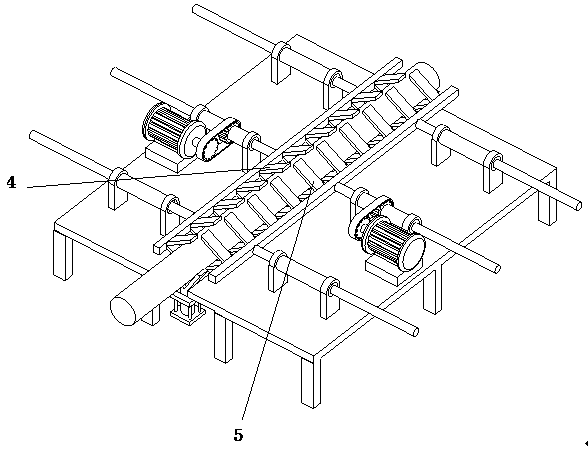

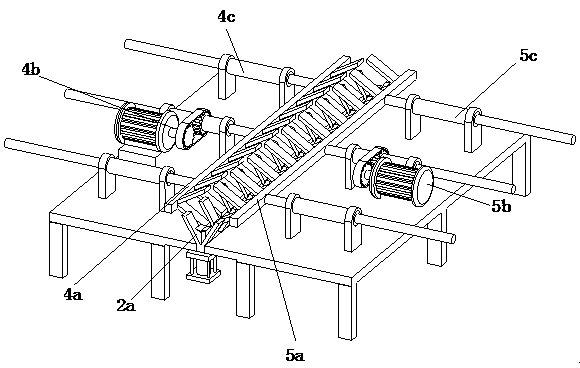

[0025] refer to Figure 1 to Figure 6 The positioning device for a PA nylon rod shown includes a supporting mechanism 2 for supporting the nylon rod 1 and a clamping mechanism 3 for clamping the nylon rod 1 on the supporting mechanism 2. The clamping mechanism 3 includes a supporting part 2a for supporting the nylon rod 1 and a lifting assembly for driving the nylon rod 1 up and down, and the clamping mechanism 3 includes a symmetrically arranged first clamping mechanism 4 and a second clamping mechanism 5 , the first clamping mechanism 4 includes a V-shaped first clamping portion 4a that interferes with the cylindrical side of the nylon rod 1 and a first clamping portion 4a that drives the first clamping portion 4a to travel in a direction perpendicular to the axis of the nylon rod 1. A drive assembly 4b, the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com