STM32-based numerical control laser cutting machine device

A CNC laser and cutting machine technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as failure of electrical components, cutting materials into waste, and the cutting head cannot be fixed, so as to achieve a firm cutting head. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

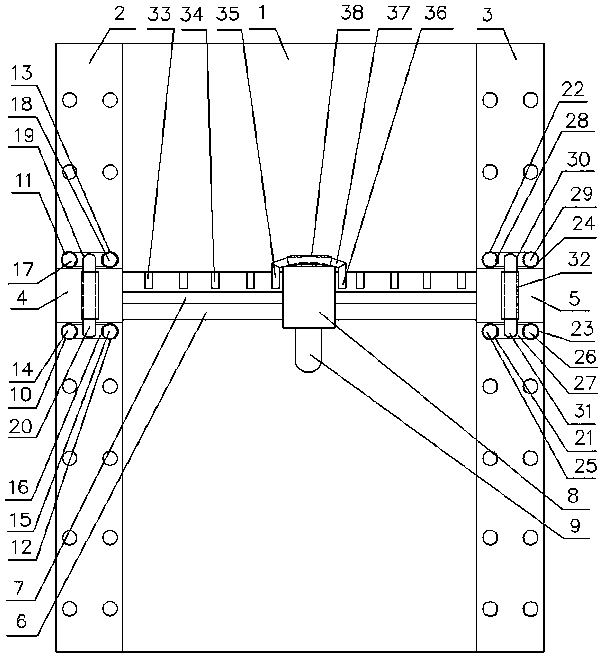

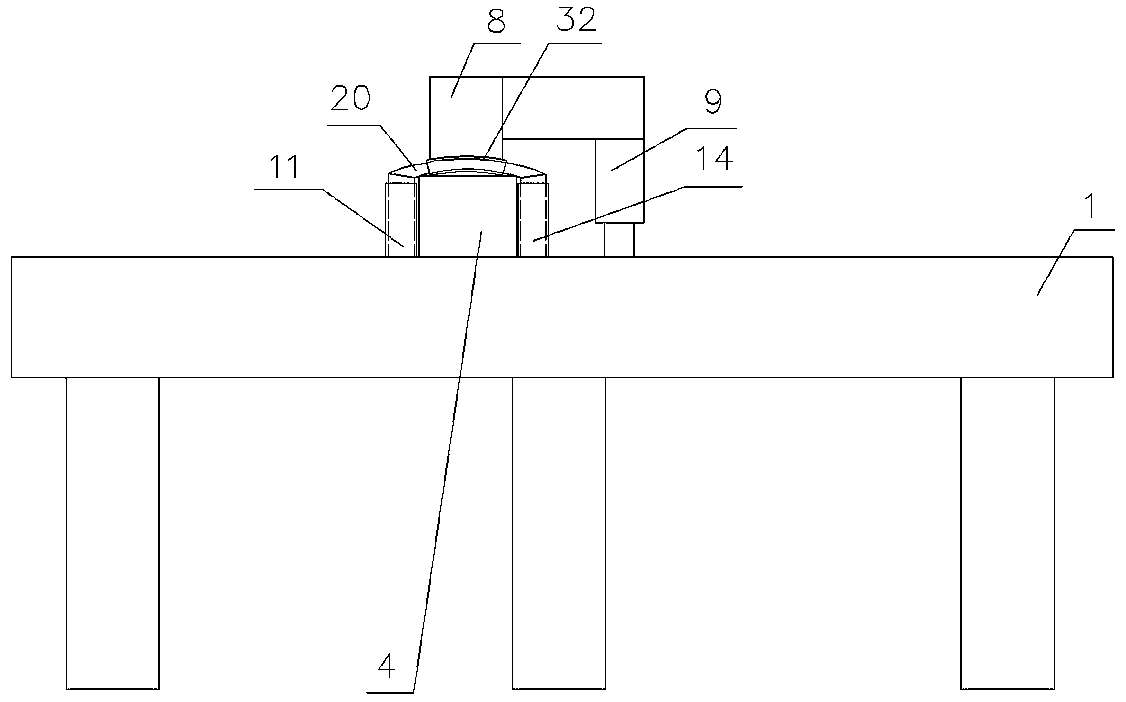

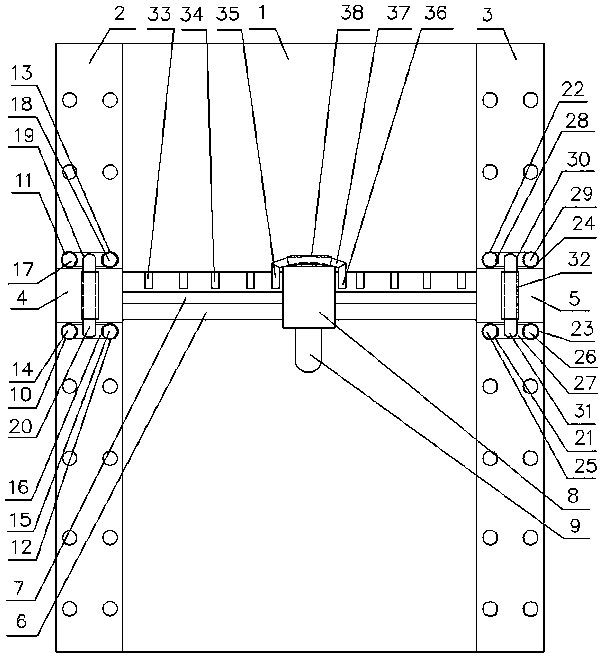

[0022] A kind of numerical control laser cutting machine device based on STM32, its composition comprises: CNC laser cutting machine body 1, described numerical control laser cutting machine body has left slideway 2 and right slideway 3, and described left slideway connects left sliding Part 4, the right slide is connected to the right slide 5, the left slide and the right slide are connected by a cross slide beam 6, the cross slide beam has a cross slide 7, the Said horizontal slideway is connected with horizontal slide member 8, said horizontal slide piece is connected with cutting head 9, said left slideway has a group of vertically arranged left front square fixing holes 10, left rear square fixing holes 11, right front square Fixing hole 12, right rear square fixing hole 13, in described left front square fixing hole, tightly fit and insert left front rod 14, in described right front square fixing hole, tightly fit and insert right front rod 15, described left front rod an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com