Suction-type rotary sand-blasting and powder-spraying device

A suction-type, sandblasting technology, which is applied in the direction of explosion generation device, abrasive feeding device, spray gun, etc., can solve the problem of uneven distribution, achieve the effect of uniform distribution, small equipment size, and reduce wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

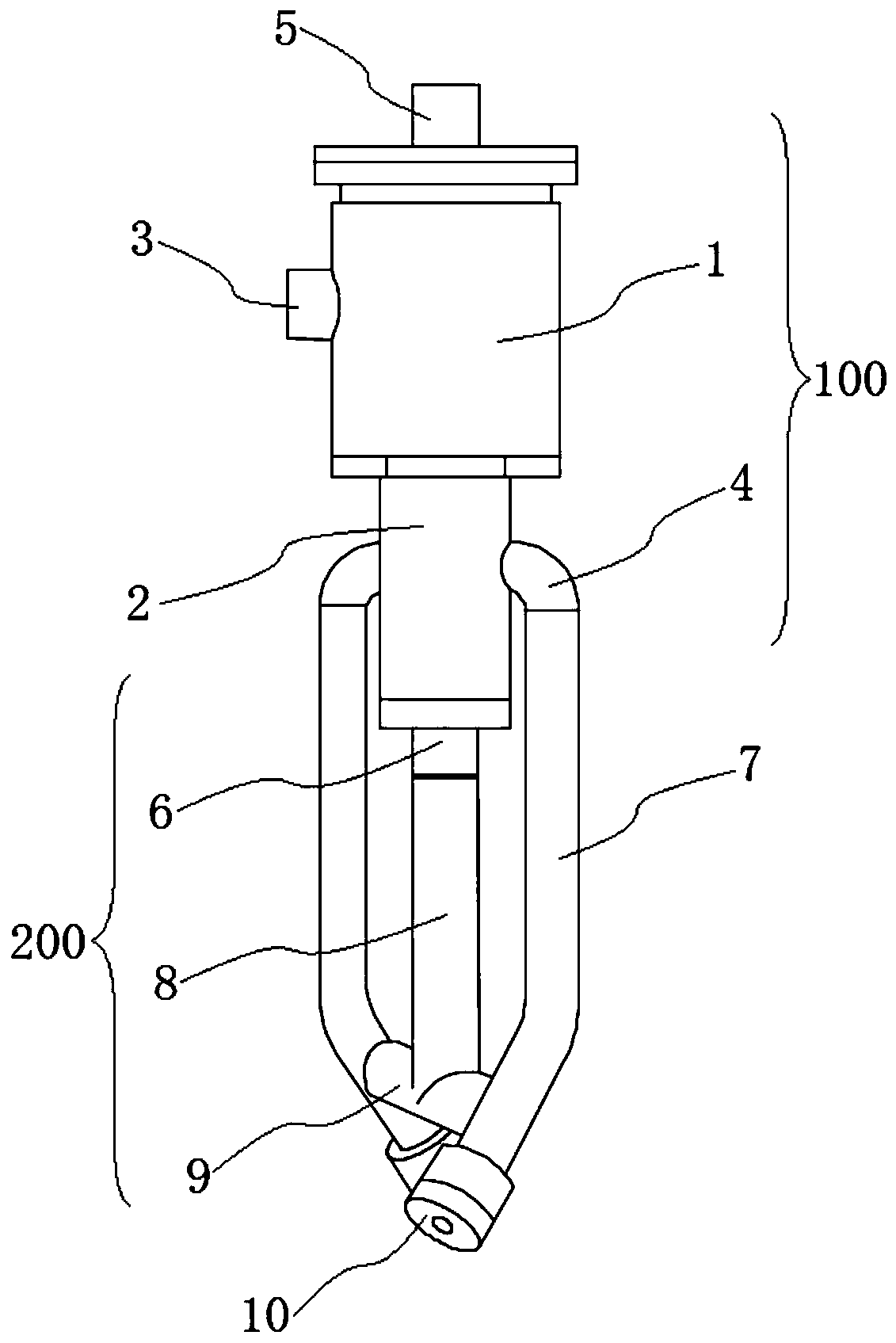

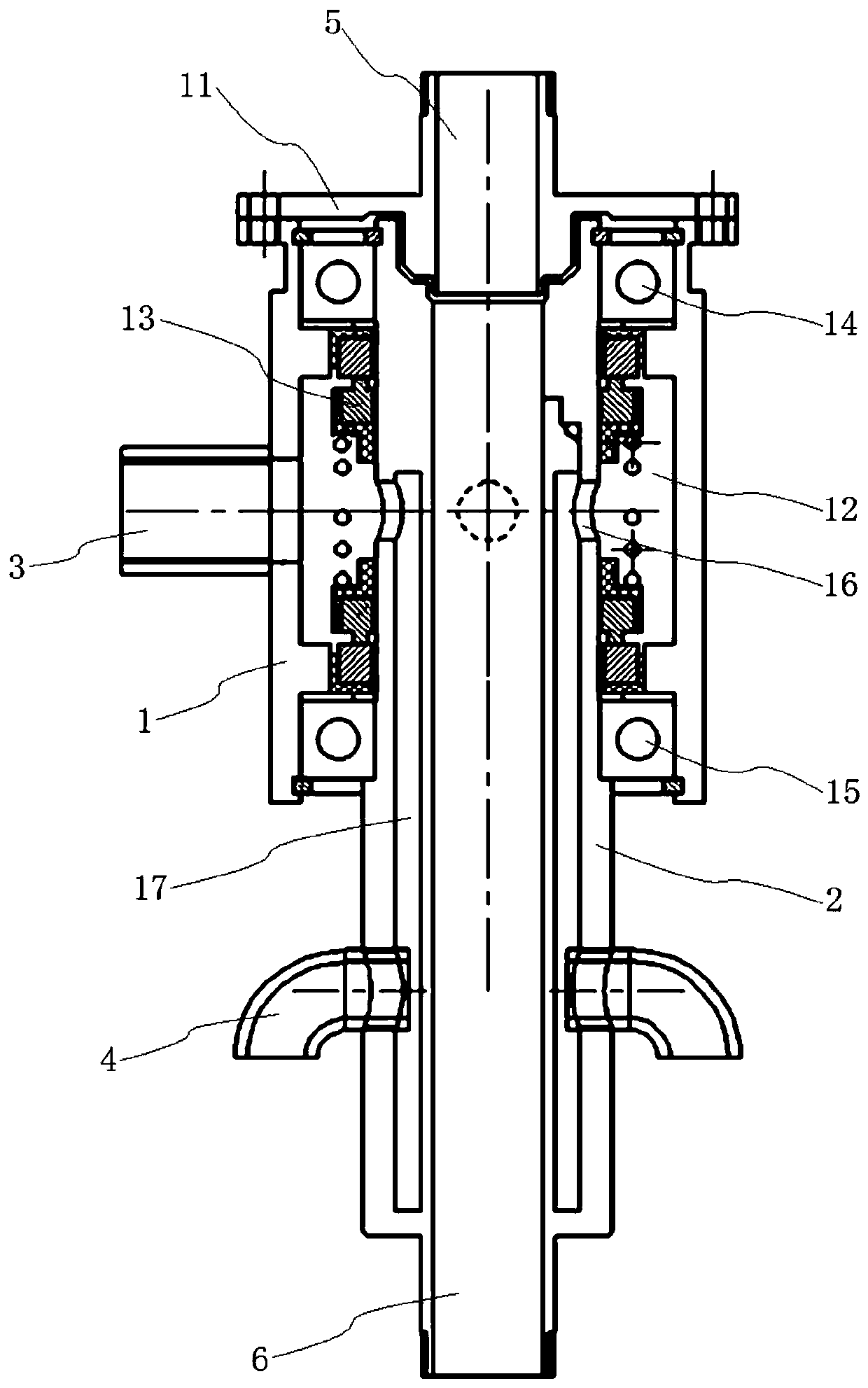

[0034] combine figure 1 and figure 2 As shown, a suction-type rotary sandblasting and powder spraying device of this embodiment includes two parts: a rotary sealing seat 100 and a suction-type sandblasting gun 200. The rotary sealing seat 100 is used to input mutually independent two-phase fluid media, and has Rotary function, suction blasting gun 200 is used to provide rotary drive and negative pressure suction spraying of solid particles. in,

[0035] Such as figure 2As shown, the rotary seal seat 100 is a hermetic rotary connector for 360°rotation conveying fluid medium, which includes a static outer cylinder 1 and a central axis tube 2, and the central axis tube 2 is rotatably installed in the static outer cylinder 1, in order to To ensure the low-resistance operation of the sealed rotating seat 100, in this embodiment, the static outer cylinder 1 and the central axis tube 2 are preferably connected through bearing rotation, that is, the two ends of the static outer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com