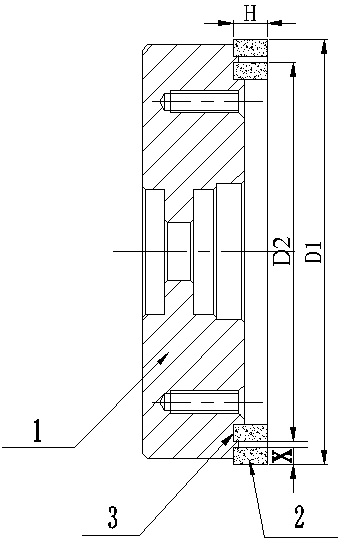

Grinding wheel applied to liquid crystal glass chamfering and manufacturing method thereof

A technology of liquid crystal glass and grinding wheel, which is applied in the field of ultra-precision processing of substrate substrates, can solve the problems of large chipping, product scrapping, fragmentation, etc., and achieve the effect of reducing strength and good holding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method for a grinding wheel applied to liquid crystal glass chamfering, comprising the steps of:

[0038] (1) Coarse grinding layer binder configuration: the binder consists of 10wt% Sn-Cu alloy powder (Sn and Cu mass ratio 34.5︰65.5), and 80wt% Ag-Ni alloy powder (Ag and Ni mass ratio is 37︰63), composed of 10wt% paraffin. Weigh the raw materials of the binder in proportion, mix them evenly, and weigh the 80-mesh diamond and the mixed binder according to the mass ratio of diamond and binder of 1:5. Mix the mixture of diamond and binder with absolute ethanol at a mass ratio of 1:8, stir for 30 minutes at a stirring speed of 1200rpm / min, and finally dry it in an oven at 90°C for 4 hours and pass through a 140-mesh sieve Get the mix.

[0039] (2) Put the mixed material in step (1) into a graphite mold of the corresponding size, and press it into a coarse grinding layer under a pressure of 2MPa after holding at 45°C for 30 minutes, at 200°C for 20 minutes, at...

Embodiment 2

[0044] A preparation method for a grinding wheel applied to liquid crystal glass chamfering, comprising the steps of:

[0045] (1) Coarse grinding layer binder configuration: the binder consists of 30wt% Sn-Cu alloy powder (the mass ratio of Sn and Cu is 42:58), and 60wt% Ag-Ni alloy powder (the mass ratio of Ag and Ni 22:78), 10wt% paraffin composition. Weigh the raw materials of the binder in proportion, mix them well, and then weigh the 120 mesh diamond and the mixed binder according to the mass ratio of diamond and binder of 1:10. Put the diamond and bonding agent into the mixture of diamond and bonding agent and absolute ethanol according to the mass ratio of 1:9, stir for 50 minutes, the stirring speed is 1200rpm / min, and finally put it in an oven at 120°C Dry for 2 hours, and sieve 140 mesh to obtain the mixture.

[0046] (2) Put the mixture in step (1) into a graphite mold of the corresponding size, and under a pressure of 10MPa, hold it at 45°C for 30 minutes, at 20...

Embodiment 3

[0051] A preparation method for a grinding wheel applied to liquid crystal glass chamfering, comprising the steps of:

[0052] (1) Coarse grinding layer binder configuration: the binder consists of 15wt% Sn-Cu alloy powder (the mass ratio of Sn and Cu is 33:67), and 60wt% Ag-Ni alloy powder (the mass ratio of Ag-Ni 20:80), 25wt% paraffin composition. Weigh the raw materials of the binder in proportion, mix them well, and then weigh the diamond and the mixed binder according to the mass ratio of 140 mesh diamond and binder 1:8. Put the diamond and the binder into absolute ethanol, stir for 40 minutes at a stirring speed of 1200rpm / min, and finally place it in an oven at 100°C for 3 hours to dry, and sieve through a 120-mesh sieve to obtain the mixture.

[0053] (2) Put the mixture into a graphite mold of corresponding size, under the pressure of 6MPa, hold at 45°C for 30 minutes, at 200°C for 20 minutes, at 400°C for 15 minutes, at 650°C for 20 minutes, and press it into a coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com