Chamfering machine

A technology of a chamfering machine and a chamfering device, which is applied in the field of chamfering machines, can solve the problems of uneven product quality, low processing efficiency and difficulty, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

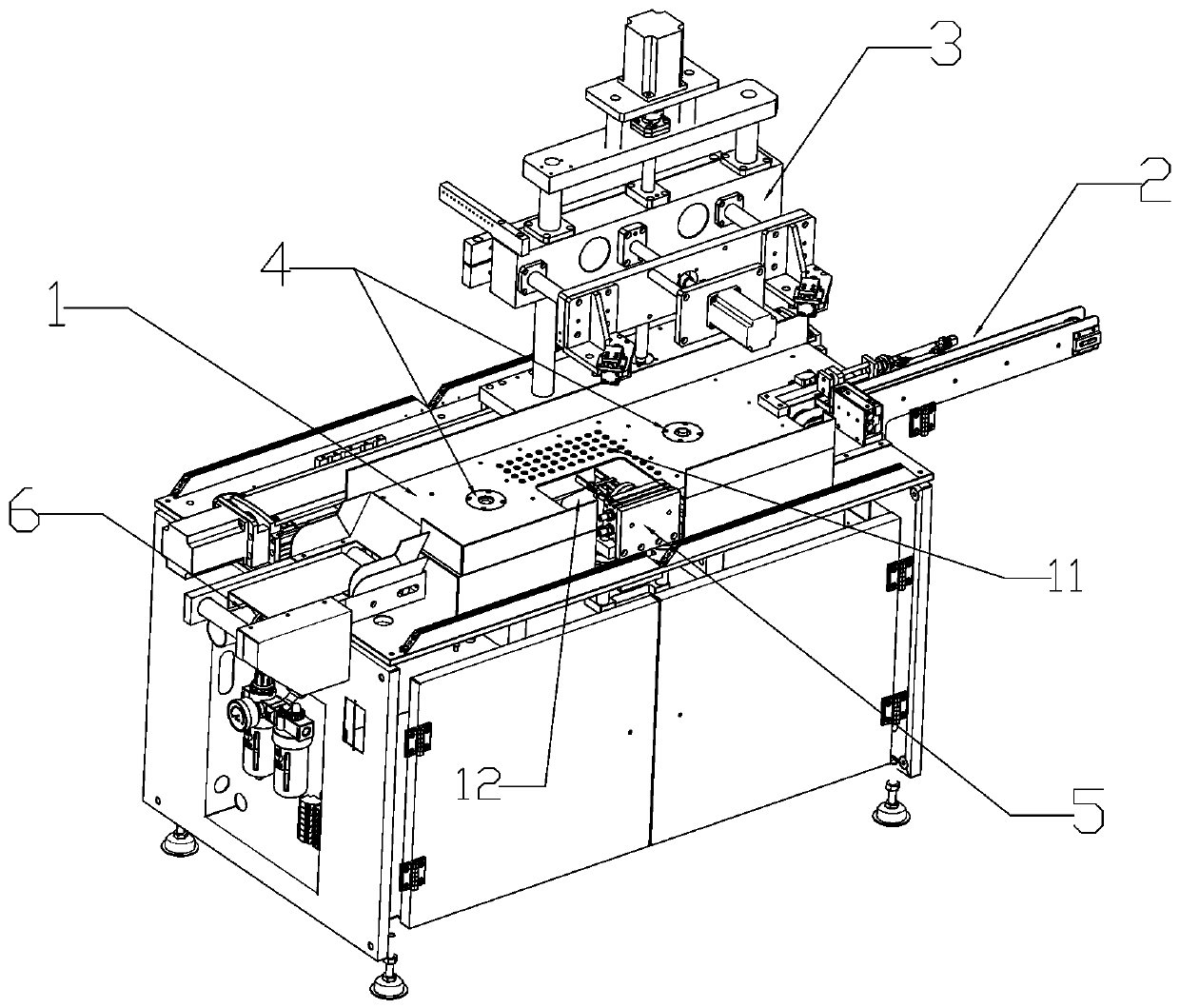

[0030] Such as figure 2 As shown, as a preferred embodiment of the present invention, the workbench 1 is provided with a plurality of dust suction through holes 11, and the bottom of the dust suction through holes 11 is provided with a dust collection tank 12, and the dust collection tank 12 is connected with the negative through a pipeline. The pressure fan is connected; a large amount of dust will be generated during the chamfering process. Under the action of the negative pressure fan, a negative pressure will be generated in the dust collection tank to suck away the dust on the workbench 1 surface and keep the workbench 1 surface clean.

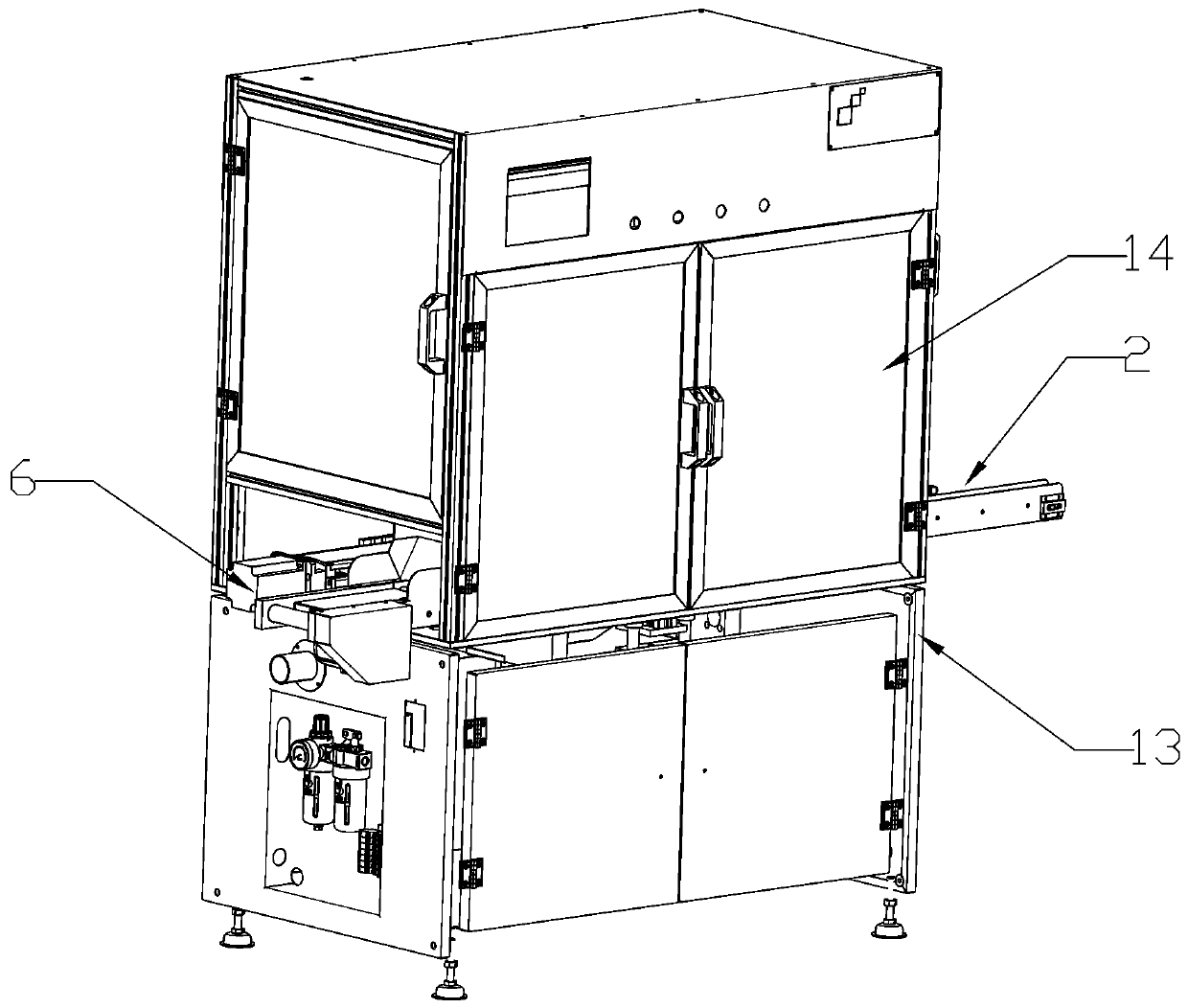

[0031] Such as figure 1 As shown, as a preferred embodiment of the present invention, the outside of the workbench 1 is also provided with a frame 13, and the outside of the frame 13 is provided with a protective door 14 to prevent waste from splashing; Blocks of waste splash and cause personal injury.

[0032] Working principle: The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com