Synchronous punching equipment at both ends of a few-shaped steel beam

A type of steel and equipment technology, applied in the field of synchronous punching equipment at both ends of several-shaped steel beams, can solve the problems of complex production, high labor intensity, and low production efficiency, achieve constant speed and stability at both ends, reduce labor intensity, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

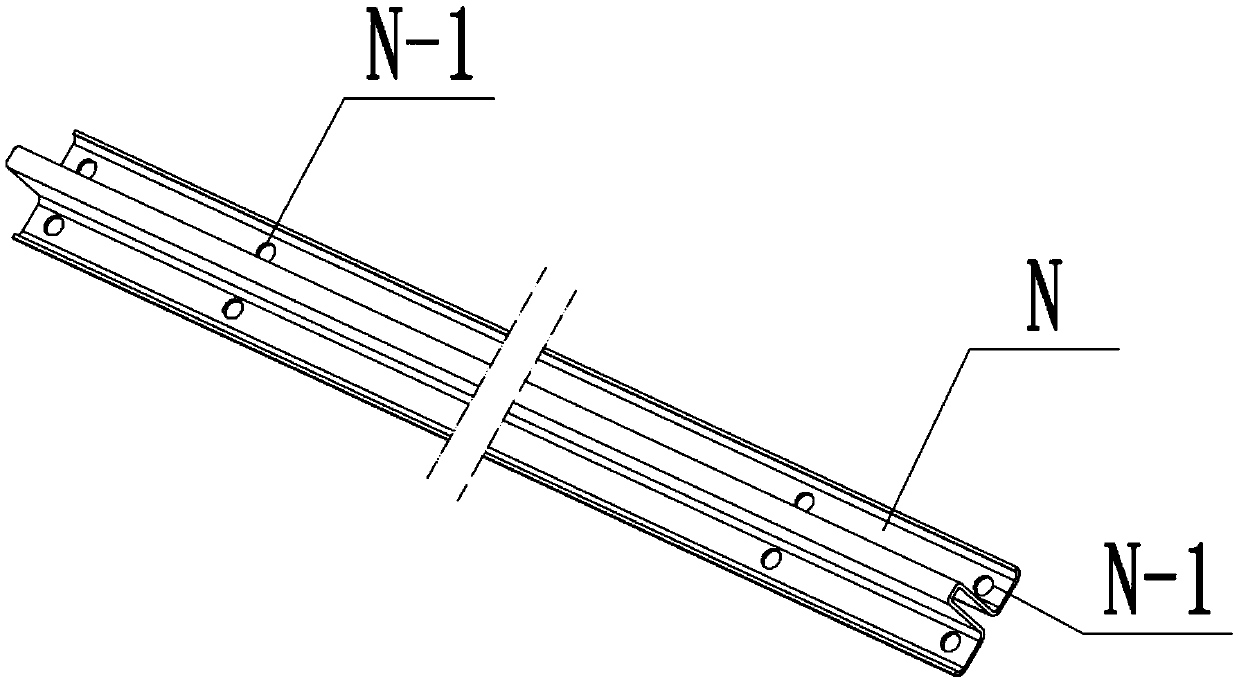

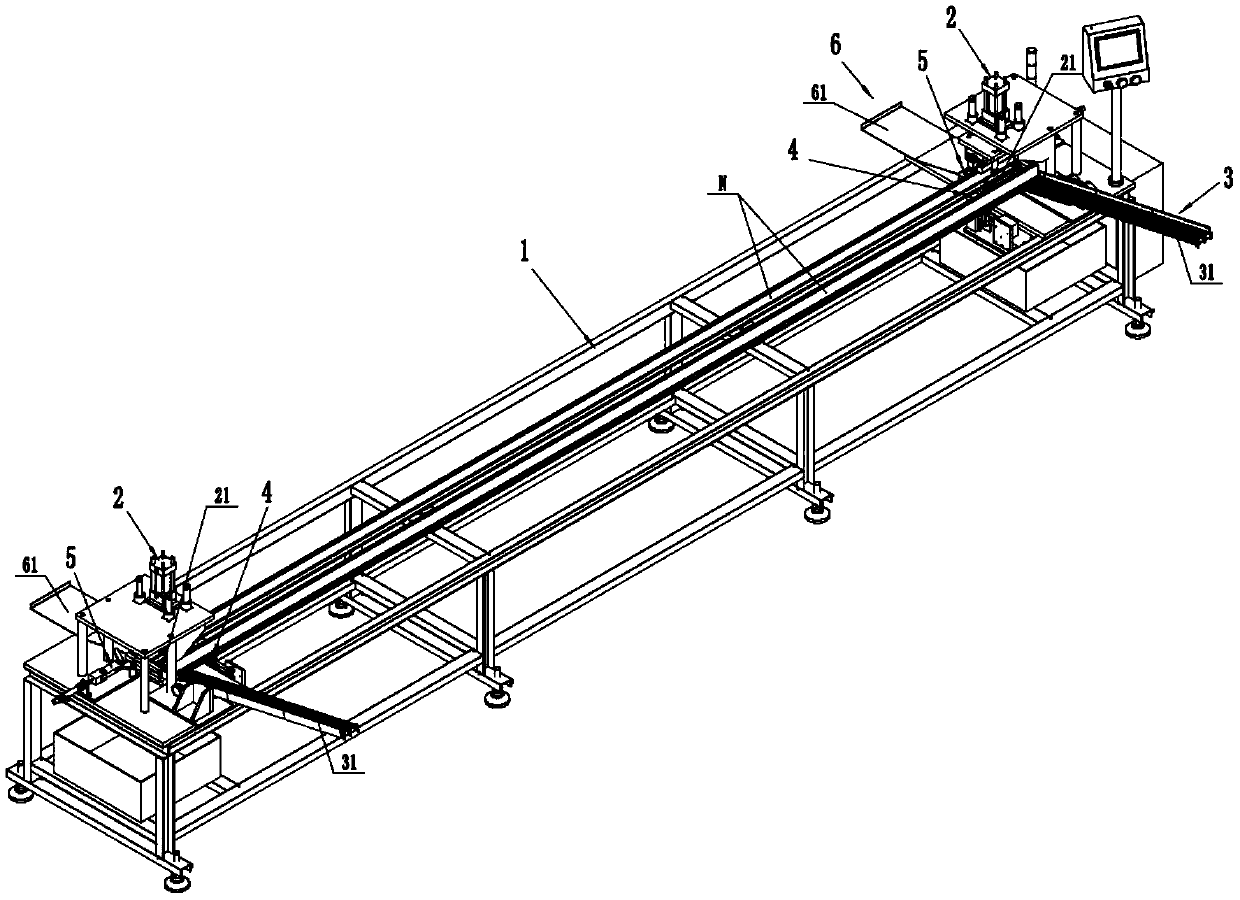

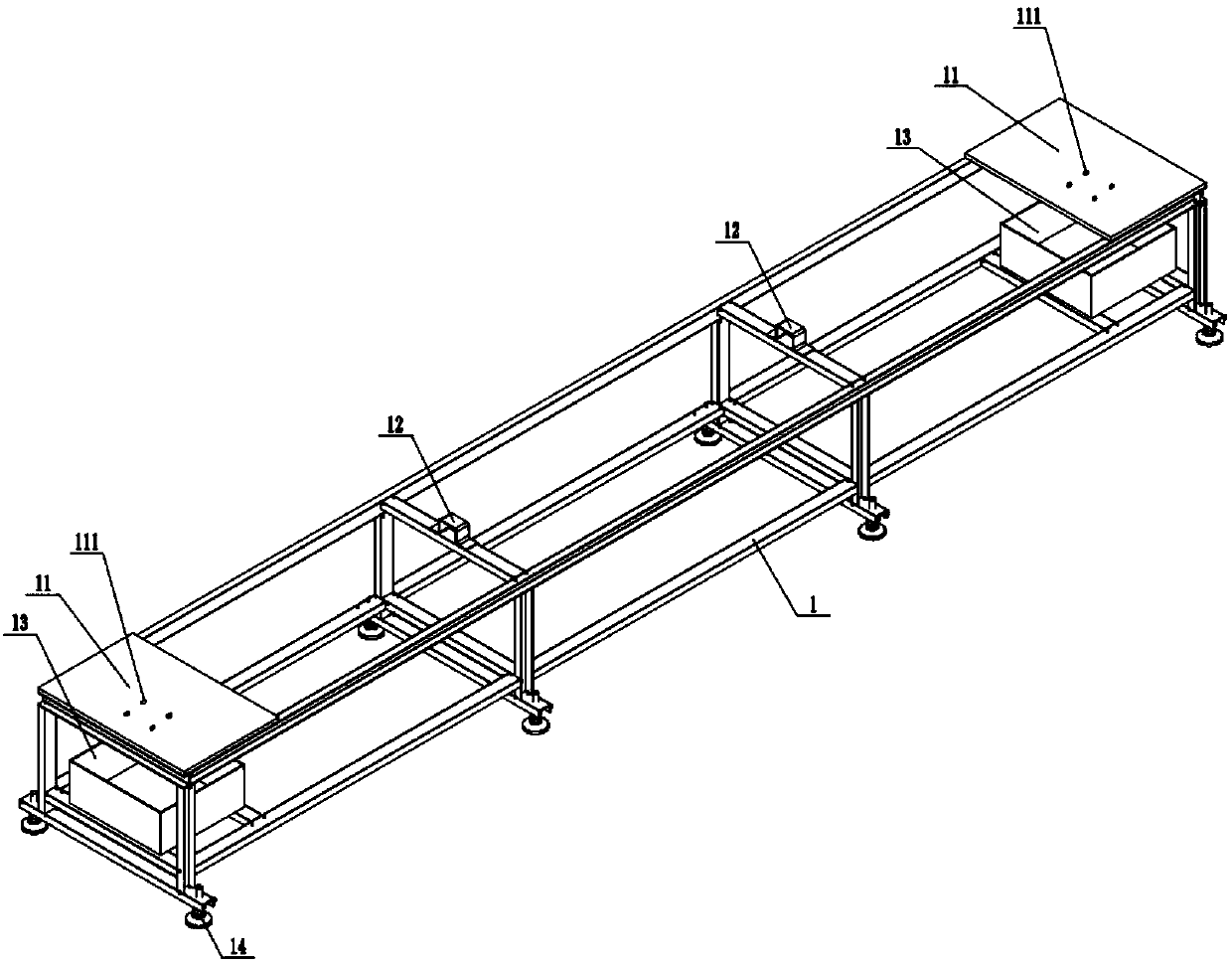

[0039] join Figure 1-16 Shown: a synchronous punching equipment at both ends of a several-shaped steel beam, which includes a frame 1, two punching mechanisms 2, a material rack 3, two discharging control mechanisms 4, and two blocking control mechanisms 5 And the material receiving frame 6, the material storing frame 3 and the material receiving frame 6 are respectively located on both sides of the width direction of the frame 1, and the two punching mechanisms 2 are located on both sides of the frame 1 along the length direction. Two discharge control mechanisms 4 are located on both sides of the frame 1 along the length direction, and the two discharge control mechanisms 4 are respectively used for synchronous blocking and synchronous release control at the two ends of the front several-shaped steel beam N; The control mechanism 5 is located on both side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com