Sheet metal visual detection acquisition terminal and method

A technology for visual inspection and collection terminals, which is applied in measurement devices, optical testing flaws/defects, instruments, etc., can solve the problems of inability to accurately measure the shape and size of the bottom of the object to be measured, affecting measurement accuracy, and poor shooting effects. Achieve the effect of prolonging the service life, flexible fill light, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

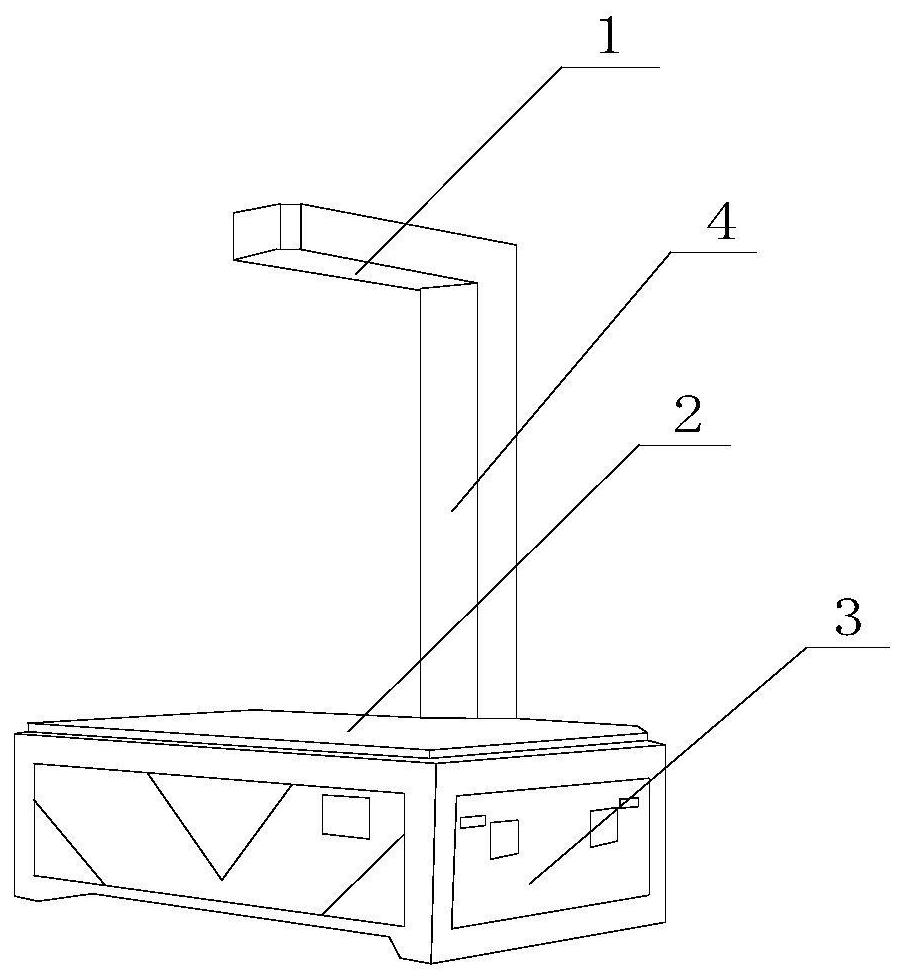

[0026] Such as figure 1 As shown, the present invention includes a sheet metal visual detection acquisition terminal, including a visual capture unit 1, a part measurement platform 2 and a uniform light unit 3, and the visual capture unit 1 includes a box body, a digital camera and a corner nut, and the corner nut is connected to the box body, the digital camera is installed in the box body through the camera base, the box body connected to the digital camera can rotate the position, and the digital camera is facing the parts measurement platform 2; Switches, frames, dodging panels and special lamps, the dosing board is installed in the frame, multiple special lamps and photosensitive sensors are evenly installed on the dosing board, the dosing board is divided into multiple units, each unit is equipped with a shading Each shading plate, multiple special lamps and multiple photosensitive sensors are connected to the controller. The controller compares the light brightness info...

Embodiment 2

[0031] This embodiment is preferably as follows on the basis of Embodiment 1: The area of the shading plate is between 4cm²-8cm². Set the area of the shading plate to a smaller area, and control the closing of the shading plate through the controller to achieve accurate light supplement. The light fill accuracy can reach between 1% and 3%, which can fully meet the needs of various types of parts. light needed.

[0032] A temperature sensor is also connected to the time delay board, and a heat dissipation unit is arranged at the bottom of the sheet metal visual detection and collection terminal 3 of the uniform light unit, and the temperature sensor is connected to the heat dissipation unit. Due to the severe heat generated by the special lamp tube, if it is not dissipated in time, it will easily cause damage to the components. The temperature sensor in this solution can collect the temperature of the uniform light unit and transmit the temperature to the delay board. At th...

Embodiment 3

[0037] The sheet metal visual detection collection method includes the following steps:

[0038] Step A) Connect the computer control switch to an external computer terminal, turn on the terminal, and place the part to be tested on the part measurement platform; Step B) import the CAD graphic file corresponding to the part to be tested on the computer terminal; Step C) the The controller compares the lighting information fed back by the photosensitive sensor with the preset value, and then automatically adjusts the number of open shading plates and special lamps, and then obtains the actual outline of the part through the digital camera; step D) the part to be tested The actual contour drawing of the actual profile is compared with the CAD graphics of the part to be tested; step E) sets the color deviation band, and represents different deviation ranges through different colors; step F) displays the deviation state of the part; step G) generates a test report; step H) Save the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com